Treat area with a large area, where much of the territory allotted to the garden, using only improvised tools is no easy task. Work on the hoeing, digging, and weeding the garden by hand takes a lot of time and effort. Well, when I have the opportunity to purchase the tillers, which will be indispensable in the area. But to facilitate work on land, and making the tillers with your own hands.

The contents

Anyone can build their own?

The market of tillers plant production offers customers a fairly wide range of products for every taste. However, the prices for such agricultural equipment is able to master not many. Therefore, in the gardens, in a rural area quite often you can find homemade tillers, which operational parameters or slightly inferior to the factory counterpart.

Creating universal design, craftsmen often use parts of old bikes and scrap metal

Outdated models of motorcycles often serve as the basis for the manufacture of different homemade and household small tools.

Because the self-made tillers are often created from scrap, old materials, and as the engine Assembly is often used known to many motor saws «Friendship».

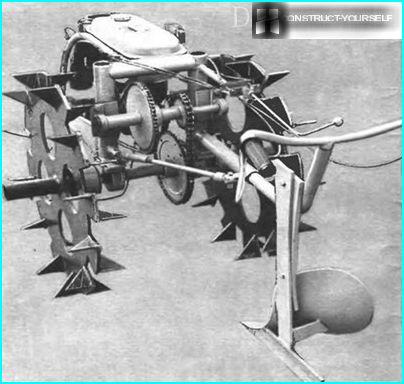

On the basis of a homemade tillers craftsmen create not less important in agriculture tools, for example: plows and Hillers for hilling corn or potatoes

One of these masters — inventor Valentin Arkhipov, who is the author of the production of many useful devices and building all kinds of household equipment.

The talented designer has created a multifunctional device which can be used not only to plow and harrow the land, but plant, hoe tuberous culture and harvest, and raking leaves

So thinking through how to make the tillers with your own hands, it is better to opt for this tested and successfully applied version. With a simple and easy-to-use SEL’khozagregat will be able to handle any man.

Built tillers according to the instructions from Arkhipova

Design features of the unit

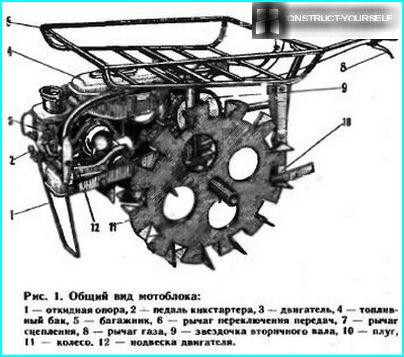

The device is a walk-behind self-propelled machines on two wheels, equipped with the engine removed from the scooter trip-150M. The reason for choosing this engine was that it has a constructive solution, through which is forced-cooled cylinder head air.

A motor scooter capable of operating at the lowest speeds on fairly large loads

For the construction of how the master used is taken from the scooter control cables, engine mount, and the double arc of the frame, arm and chain. The remaining design details were industrial production

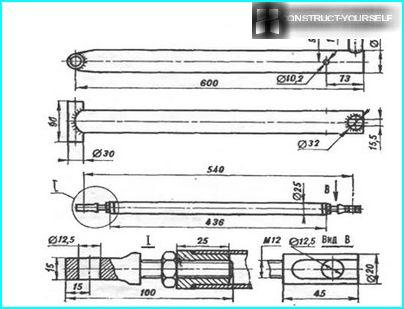

Separately, the designer has produced the welded pipe of U-shaped frame and machined on a lathe wheel axle. Did it also for the core and control rods 3 homemade hinge. They will be used as connecting elements between the motor-block, the wheel and plow.

On the skid is attached by welding steel pipe, the final axis, which is necessary for the implementation of tension going to the gearbox and the motor cables. The very tension is carried by a swinging rocker arm, as the shift lever of which is welded a section of steel pipe.

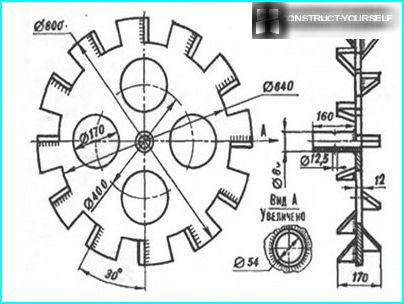

Step chains used to create the device is 12.7 mm and 15.9 mm Number of teeth of sprockets: the output shaft 11, output shaft 20 and 60, the axle – 40.

What good is this design?

Analogues of such models there are not a dozen, but in comparison, the original model tillers Kaluga masters has a number of advantages.

- Swivel. Machining tools and trucks most of these models have a rigid connection, which complicates the maneuvering of the Assembly and complicates the work with him. Details of the SEL’khozagregat connected by hinges. In the process, if necessary, to change direction without removing the plow from the furrow.

- The offset of the axis to the direction of movement. Many owners, when processing the soil with the use of the cultivator faced with the difficulty that in the process of moving forward under the action of soil resistance, the unit distracting at times. Alignment of furrows should put a lot of effort. To compensate for this drift, the wizard has located the axis of the plow at a slight angle in the direction of motion. When plowing the design turned slightly to the left. The desired position can always be adjusted by three hinges thrust.

- The level of the desired ploughing depth. If in other models, the depth of plowing is maintained by lowering or lifting of the plow when working with this cultivator it will be done automatically. Regulation is carried out by changing the angle of the plow against the furrow. The design is equipped with a field Board, which acts as a lifting force in the burying of the plow. If, however, a shield appears above ground, it instantly increases its angle of attack, under which he again sinks into the soil to a predetermined depth.

Step-by-step technology of Assembly of the device

Assembly designs begin with the development of the suspension shaft. To this he attached to the housing with bearings, welded a sprocket and is mounted overrunning clutch which in the process will carry out the function of the differential. After this, the design is equipped with wheels and frame. On the fixed frame, set the telescopic rod, the plow and the wheel.

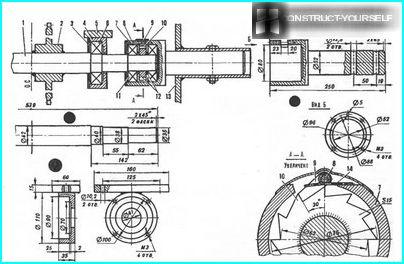

The principal elements running gear shaft: 1 — shaft, 2 — star, 3 — cover, 4 bearing body, 5 — Seating area, 6 — bearing No. 308, 7 — the case of overrunning clutches, the 8 — axle dogs, 9 — dog,10 — ratchet 11 — bearing No. 307, 12 — washer, 13 — wheel 14 — spring dog

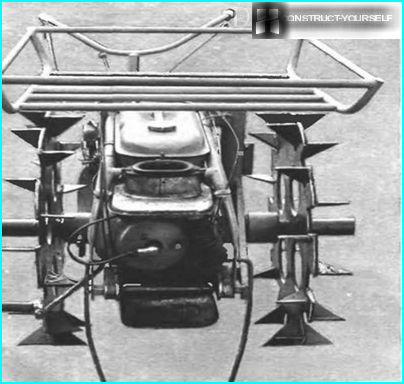

Agricultural tillers equipped with special wheels that as opposed to rubber counterparts, able to provide the best traction.

Such metal wheels are not clogged with earth. In contact with the ground they don’t condense it, but on the contrary loosened

To connect the frame Assembly with suspension, engine and frame of the scooter uses two curved pipes. Between them space to accommodate the fuel tank.

For arrangement of the engine used bracket, culminating in a steel axis with a length of 150 mm console Bracket is welded to a U-shaped frame design. On the axle hung motor with the suspension. Assembled design combined with curved arcs of the frame. Only then assemble the secondary shaft, stretch out control cables and pull chain.

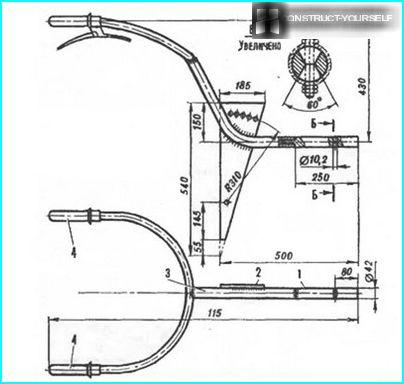

The main elements of the management node: 1 — connecting axle, 2 — strip, 3 — tube, 4 – arm

Connecting construction elements: 1 — main rod 2 regulating craving

How this whole thing works — video examples

An illustrative example of the application of tillers:

But this modification is especially good:

How else can you upgrade homemade tillers?

Tillers multifunctional Arkhipova. It can be used as a plough or cultivator. It is enough to removable parts for a plow to replace parts removed from the dumps to the cultivator. Walk-behind as you move to deepen the furrow in the ground and put them in potato tubers. To plow the tubers need only install the blades and go unit between the planted rows.

The same principle can be Spud and sprouted plants. SEL’khozagregat comfortable and at harvest. Using different heaps, you can change the width. The unit is also able to collect a missed potatoes and remaining after harvesting the tops of the plants. For these purposes it is equipped with a rake or harrow.

Universal design can be used not only for agricultural work. In the winter it is successfully used for snow removal. Faithful assistant will be useful for cleaning the tracks of the local area. Setting the walk-behind roller with a round brush and an extra asterisk, the host will facilitate a job on clearing sidewalks.