Snow time is a favorite time kids skiing and sleigh, fun games in the snow and building ice castles… But the owners of country houses, the abundance of snow is not very happy, because it is necessary again to undertake a shovel and to clear the area. Well, when I have the opportunity to acquire a snow machine to turn a seasonal service in a pleasant work. But if there is no extra money to buy useful «assistant», you can always make a thrower with his own hands from materials that have long been gathering dust idle in the corner of your workshop or shed.

The contents

Design #1 — model auger snowthrower

Preparation of the basic elements

Propose first to consider how to make snow with their hands based on the old engine of cultivator. For this you must prepare:

- Sheet (roofing) iron to build the body of the screw;

- Angle steel 50×50 mm for frame structures;

- Plywood 10 mm thick for the side parts;

- Half-inch pipe for the arrangement of the handle of the machine.

Planning to build a homemade snow thrower engine with air cooling, it is necessary to provide additional protection for the air intake openings from the emitted in the process small particles of snow.

Engine power of this device is 6.5 HP. It is enough for the cleaning of fresh snow with gardening area

Due to the width of the machine within 50 cm, it convenient move designed to clear paths on the site. The machine has compact dimensions, its width does not exceed 65 cm. This allows at any time no longer needed to hide the snowthrower in the shed, it easily passes through a normal doorway.

For the manufacture of the shaft of the screw can be used ? inch pipe. In the pipe make through propyl, required for fixing metal blades dimensions mm. 120х270 In the process captured snow mass of the conveyor screw will move the shoulder. This blade, in turn, under the action of rotation of the shaft will throw the snow to the side.

The frame of the snowthrower can be welded from steel corners 50×50 mm, but closer to the edges of the design in the tube to the transverse angles it remains only to weld two angle on each side, whose dimensions are 25×25 mm

To these parts in future will be attached to the engine platform. Bonding of the transverse angles with the longitudinal and fix them on the handles, you can use the bolts (M8).

The auger tube is equipped with a metal spatula and four rubber rings d=28 cm, material which can serve as the sidewall of the tire, or 1.5-meter conveyor belt thickness 1.5 mm.

Cut the rings from the rubber base by using simple device: at the plate to score the two screws, and then this construction firmly secure the ribbon and to rotate in a circle. To simplify the procedure of cutting out using a jigsaw

Sigourney because the auger of the machine rotates in savantium bearings 205, place them on the pipe. In order to make the snowthrower, you can use any bearings, the main thing — they should be enclosed. As a protective casing for the bearing may be a bearing from the cardan shaft of the old models of Lada.

Council. To design were well into the bearings, it is necessary to make a couple of cuts and slightly obstuchal. Such manipulations allow to reduce the diameter of the shaft.

For insurance homemade auger from penetrating the ice it is desirable to provide a safety pin. In addition to the direct purpose – cut in case of jamming of the screw, it will serve as a belt guard (if you equip the belt system). The auger drive can be realized and chain. The frequency of rotation idling goes to about 800 rpm All the necessary components of a snowplow can be purchased at any specialty store.

For snow removal a good fit cut the plastic sewer pipe d=160 mm. It is fixed on a pipe of the same diameter, placed on the body of the screw

Continuation of this segment of pipe will be the discharge chute of the snow, the diameter of which must be greater than the width of the metal blades of the auger.

Assembly design

Before Assembly, the design should pay attention to the fact that the size of the machine body needs a couple of inches to exceed the dimensions of the auger. This would prevent the interference mechanism of the housing walls in the process.

Since the engine of the snow thrower in the snow-free periods can also be used for other purposes in the construction of the unit it is desirable to provide a convenient quick-release platform, which the engine at any time can be removed without requiring any tools.

A significant advantage of such a constructive solution is the ease of cleaning of the housing and the movable parts of the machine from utrambovyvaya snow. And to get rid of this snow thrower for storage is much simpler: it is enough to remove the engine and the car will be twice as easier.

The basis for the skis are wooden beams, which is additionally equipped with plastic covers. To produce such plates from the box from the wiring harness

The snow thrower is ready for use. It remains only to paint a self-made device and get to work on clearing snow.

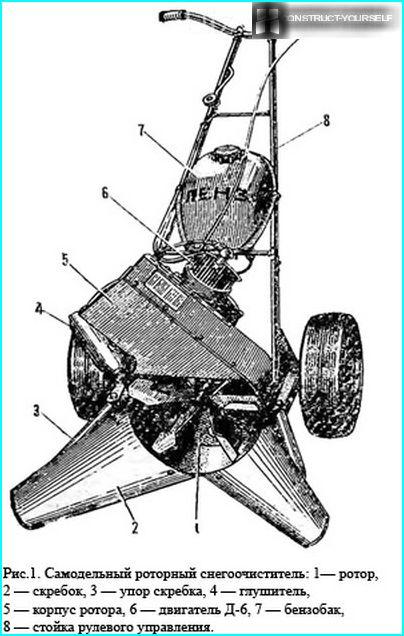

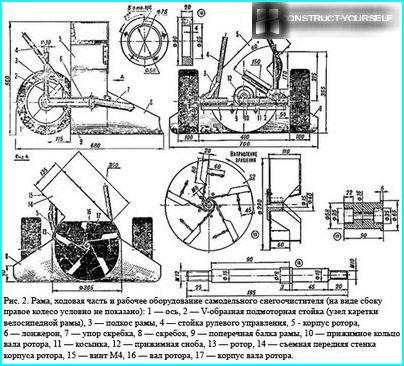

Design #2 — rotary snow blower «Blizzard»

This is quite simple in design, the unit can be done in any workshop equipped with a lathe and a welding machine. Designed Penza artisans snegopady showed himself well even in fairly heavy snow conditions of the notes.

The basic structure of the device consists of a motor with built-in muffler, gas tank and throttle cable for throttle control.

All the components of the device can be purchased in the store or take the same motorbike

First we need to manufacture the rotor on a lathe based on the corresponding workpiece from part of the motor. It looks like a steel disc d=290 mm and a thickness of 2 mm. Disk, connecting with the bolts with the hub, forms the structure to which already fastened by welding of the blades 5. To improve the efficiency of the mechanism of the blade further from the back side strengthened with ribs.

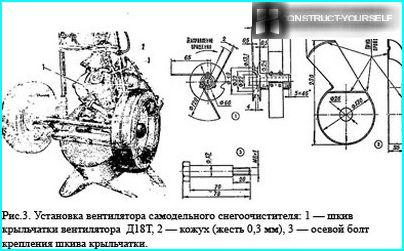

Cooling system motor works on the principle of fan blades which are made from duralumin and fixed on the pulley to start the motor

The solder protects the fan casing is placed on the crankcase cover. To improve the quality of cooling the cylinder head is placed at an angle of 90 degrees.

On the rotor housing is seated on the shaft are placed in pairs four ball bearings. It is fixed to the housing by means of steel clamping ring and bolts. The body of rotor is pressed against the frame using a special bracket, which partially captures the compression ring.

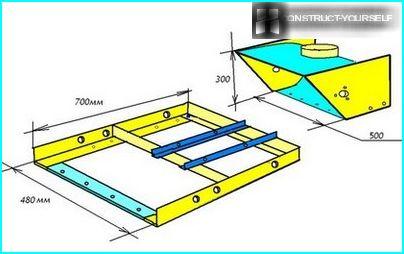

Assembly drawings of the main elements of a snowplow «Blizzard»

Removable elements of the machine are aluminum wall of the rotor body and placed along the frame scrapers.

A significant advantage of the homemade snow machines is the ability by changing the scrapers to adjust the width. At the height and quality characteristics of the unit. The weight of the structure does not exceed 18 kg, which gives the possibility to use it with women, and the range of snow removal — about 8 meters.