Sometimes vegetables and fruits is really cheaper to buy in the store. But the quality of the products grown on your own is always more confidence. Besides working the land increases vitality if you do it wisely. But heavy physical labor are not always useful, especially for those who are accustomed to work only in the office. To spring chores were pleasant and not too burdensome, you need to get by means of minor mechanization. Modern technology can certainly buy, but it turned out that to make, for example, the cultivator with your hands simply. Check this.

The contents

Option #1: manual tornado – death to the weeds

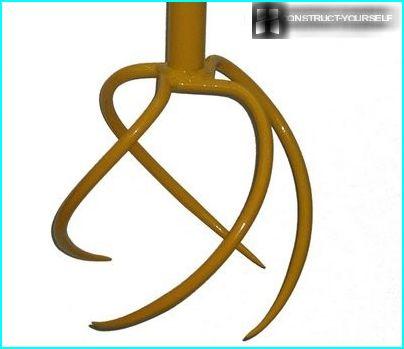

Tornado is a hand cultivator, which can and must be done by hand. Having such a device resembling a curved fork, you can forget about the endless battle with weeds. The teeth of the tool at an angle digging into the ground, then a Tornado should rotate and lift. It does not have to exert excessive effort, because instead of the usual knobs have a Tornado there is a lever.

Cultivator Tornado attracts the fact that it is quite easy to use and does not require any significant effort

All good this wonderful corneoscleral, but familiarity with its shop price can completely fight off the desire to become its owner. However, nothing complicated in this fixture no. Cultivator Tornado can be done independently, and even in several different ways.

Tornado of springy steel

We will need a steel tape of length 50 cm, 1-1. 5 mm thickness and 2 cm width. For our purpose it is best to use spring steel. Bend the tape in the form of a loop and fasten to the wooden haft of a tool. The length of the stalk depends on the growth of the owner: to operate the tool should be convenient. You can make the lever, the same as in store cornudella. Working steel loop should be with a diameter of 20 cm, which is slightly less than the width of the aisles. Edge loops to sharpen with a file with two sides.

Weeds — the fork in the side

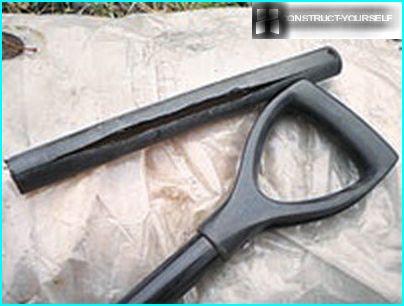

If a Tornado similar to a pitchfork, why this familiar to all gardeners tool and do manual cultivator with your hands? Buy at the hardware store conventional forks and give the teeth of this tool is needed to bend with a hammer. In General, the tool should resemble a kind of tailspin. It is important not to hurry and to proceed with caution.

For arm you will need a two foot long section of plastic pipe. Buy in the store and a plastic handle with a nozzle for the stem, which is used for forks or shovels. The tube in half lengthwise, put on handle and fasten with tape so it does not slip. Now the arm stands about 25 cm from the handle on both sides.

It is logical to do viloobraznym part of the Tornado is from vil – familiar to all gardeners tool that everyone has

An important part for the cultivator Tornado is the upper part of the lever: the lever is possible with minimum effort, to do the heavy work

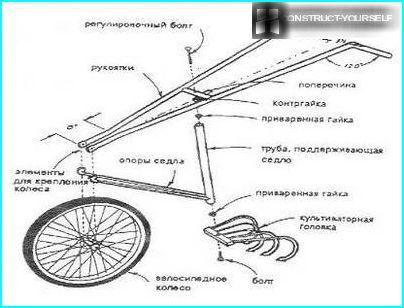

Option #2: plane on the basis of the bike

Cultivator-a cultivator will help to cope with weeds and will greatly facilitate the life of any gardener. Structurally, it is harder than a Tornado, but not much.

To create plane you need:

- old bike that no one uses for its intended purpose;

- head worn cultivator or the working surface is a two-handed saw;

- drill, grinder, wrenches, drill bits, bolts and so on.

From bike useful the frame and one wheel. Attached to the frame of the cultivator head. In the same capacity can be used, the cutting part of a two-handed saw, a small plow or sharp steel rods manufactured on their own. Arm for control mechanism is made of aluminum or steel pipes. Scrap pipe about 2.5 cm in diameter will come in handy as the lug.

The cultivator can be done on the basis of the old bike, using as the cutting of the work surface two-handed saws, ironically called «Friendship»

No special difficulties in the design of this convenient tool is not present, it can be done with any material

Construction should be rigid, so the nodes are pulled together by bolts. The wheel is medium in size should be fastened to the frame with lock nuts. A self-made tiller, which is very functional and easy to use.

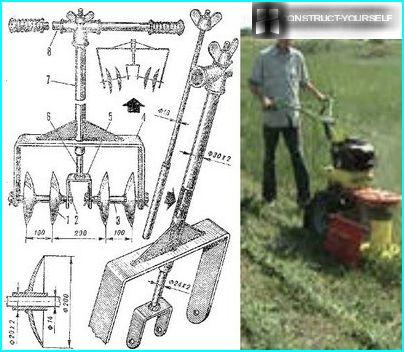

Option #3: disc rotary cultivator

To do with your hands rotary cultivator is not easy. For this you need special skills and good physical preparation. If all these qualities you have, you can try to build this tool, which will be much more effective than all previous. It can be used not only to cultivate, but to harrow the ground, deftly breaking up large clods.

In the composition of the disk rotary cultivator: 1 — disc, 2 — axis. 3 — sleeve, 4 — clip large, 5 — clip small, 6 — rod, 7 — pipe, 8 — pen

The working bodies of the cultivator are convex discs that need to be welded to the sleeves, put on an axis. The axial ends are fixed pins which are fixed in a large clip. Then at the top of this bracket is cut out the hole. It secured the arm bar. To a small bracket to weld the stock length of 25 cm and a diameter of 24 mm. it screwed rod 16 mm diameter. Portion of the rod protrudes above the crossbar.

The desired spherical shape to a disk 4 mm thick to give a not so easy. It needs to be able to deftly handle the hammer. A strong and accurate shot in the center of the disc and converts it into the bowl. Here on this and need major physical effort. Special wing nuts, located on the crossbar, adjust the angle of tilt of the spherical disks to the direction of movement of the cultivator.

Option #4: production the grinder to help us

All of the above equipment is quite simple. But in our own workshop you can make a homemade electric cultivator. This proves once again that the possibilities of DIY are almost limitless. For the realization of this idea will need the old industrial grinder. Based on it and will be constructed effective electrical assistant gardener.

Electric cultivator can be done on the basis grinder industrial purpose: get a sufficiently powerful machine that will last several years

It’s not so difficult as it seems, if you have a welder and master, able to use it as intended. To the gear housing it is necessary to attach two corner. To the corners of the welded pipe bend to be used as handles. Between the arms are welded another piece of pipe – spacer, giving the structure the desired strength.

The corners will be welded and the axis for the wheels of the cultivator. Wheel select the medium size to be comfortable and sinking into the soil.

The main part of the design is the shaft. To carve his have from the usual scrap. The connection is as input in the slot. Nozzle grinder oblivaetsya with a sledgehammer, leaving Bush with thick walls of cast iron. In it are placed carved from scrap preparation, to which is welded lugs in the shape of a screw. They are cut from automotive leaf springs. Was used and other options for lugs, but they proved unsustainable.

The lugs are arranged at an angle of 120 degrees. They need helical to turn in the direction of rotation, then it will be easier to enter into the land, and the cultivator will be easier to manage. The engine unit is connected according to the scheme «triangle», the start – capacitor. The motor switch for convenience, is mounted on the handle of the cultivator. The machine will last a long time if before beginning work to lubricate the pair improvised shaft in a cast iron bushing any used oil.

Take a good look at what should be the lugs and how they should be: on this depends the efficiency of your appliance and its durability

The quality of cultivation depends on the speed of movement of the cultivator. Quick plowing is a tough and slow — the land can be literally recycled to a state of dust.

Option #5: child’s bike and a washing machine

Do not rush to throw an old Bicycle and old washing machine. These things can still be useful, if you wish to make the cultivator with his own hands, spending a minimum of means.

Now You know how to make the cultivator. It remains to apply their knowledge in practice.