The contents

- Plastic panels

- Wall panels for corridor MDF

- Panels of natural wood

- Panels MDF

- A variety of wall panels

The wall in the hallway, especially if you have small children or Pets, are subjected to various damage and dirt a lot more than in other areas. That is why finishing materials for hallway and corridor should be selected with special care, because this part of the house – the first thing you see come visit.

Finishing materials that can be used in such cases are many, and each of them has its own advantages and disadvantages.

Plastic panels ↑

Panel made of PVC represent an artificial material, which contain no cadmium or asbestos. Due to their cellular structure they are ideal in situations when you want to provide quality sound insulation.

Among the main advantages of plastic panels are the following:

- huge selection of colors and patterns;

- the presence of the protective coating providing good resistance to sunlight;

- the possibility of use in rooms with high humidity levels;

- convenient care;

However, given the fact that the artificial material, these panels are not recommended for use in decoration of residential premises.

Wall panels for corridor MDF ↑

In the manufacture of MDF panels used fine shavings and wood dust, which are pressed under high temperature and high pressure.

Panel whose thickness reaches 16 mm, similar in appearance to wood.

The advantages of MDF panels include:

- reliable and sturdy, easy to cut;

- increase the heat and sound insulation;

- in the market you can find panels with waterproof and fireproof impregnation;

- you can use when decorating any room, but the advantageous of all, they look in the hallway and the hallway.

Panels of natural wood ↑

In the manufacture of such panels used solid rock, and wood with veneer from natural wood. The main materials are: alder, cedar, oak, ash, pine, beech and maple.

Once the panels are fabricated, they are impregnated with special compounds so that the material is resistant to moisture and fire.

- Veneered panel includes several layers. The core layer made from pine, very cheap materials. Then it is glued of two or three-ply veneer, on top of which the final paste (from valuable breeds).

- Bond the layers to each other occurs by means of hot pressing.

- In conclusion, the panel carefully polished, then coated with varnish, paint or wax.

The most expensive are the panels made of precious wood, with further polishing.

Panels MDF ↑

Manufacture drevesno-fibrous plates is carried out by hot pressing of wood fibers, which allows to produce lignin (an organic binder). It eliminates in the production the use of synthetic thickening agents.

The advantages of MDF panels include:

- the possibility of use in residential areas, as the fiberboard panels are environmentally friendly material;

- they are water resistant, so they can be washed as necessary;

- these panels, due to its appearance, perfect for decoration in hall and corridor.

A variety of wall panels ↑

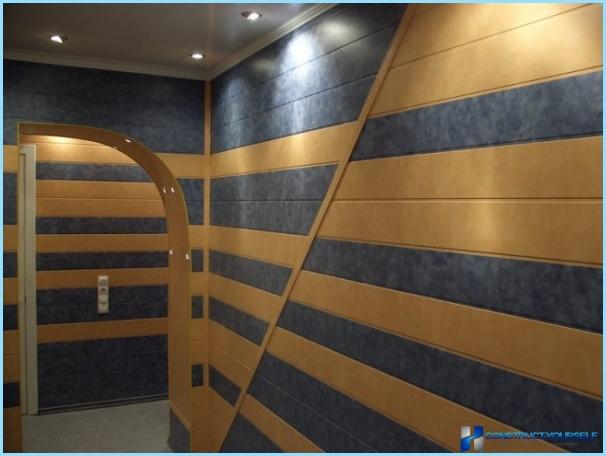

Today wall panels for corridor available in various colors, textures and sizes. In line with this, all the panels are divided among themselves by several types.

Tile panel ↑

Tile panel in its outward appearance similar to ceramic tiles, but on the back they have a fastening system «the tongue-and-groove». These panels can be used for decoration as the main material, or in combination with other types of finishes, creating a striking and unusual composition. Produced in various colors, often complemented with different finishes.

Rack panels ↑

In its external appearance this material is very similar to the usual battens, but they also come with a mounting system «the tongue-and-groove», so that installation becomes much easier. In most cases, their height is from 2.5 to 6 meters and the width reaches from 10 to 40 centimeters.

Sheet panels ↑

These panels are manufactured as a monolithic, homogeneous sheets, is further embellished in various patterns. They are often used for walls custom sizes. The main feature of the panels is the possibility of their installation on a flat wall without additional funds.

Rules for the selection of wall panels for corridor ↑

Select panel for the decoration of your corridor should be focusing not only on their idea of beauty, but also the characteristics of each material. If the front side of the selected panels coated with wax, it means that the material has good resistance to moisture. However, in corridors with high humidity is not so frequent, so this feature can be considered optional.

MDF ↑

Panels made of MDF are very strong, they are able to improve significantly the level of heat and sound insulation in the room. If they are required for finishing of the room in which the air temperature is high, it is necessary to notice that in such circumstances the material quickly loses its attractive appearance.

Plastic ↑

Wall panels for corridor PVC is ideal in those cases, if the room requires additional soundproofing. They are a boon if you want the implementation of design solutions, because these finishes can be not only matte, but glossy, cellular, with designs and patterns. An important advantage is the ease of maintenance, because to clean the panels of dirt, they simply wash. Their main drawback is the artificiality of the material.

Tree ↑

The tree stands in first place in the list of the most popular materials for the walls. The appearance of these panels is able to make the home more comfortable, but the material is one of the most expensive.

Particleboard and fiberboard ↑

The main positive feature of this material is its low cost. Perfect in cases where a simple trim with no frills. The downside is low durability.

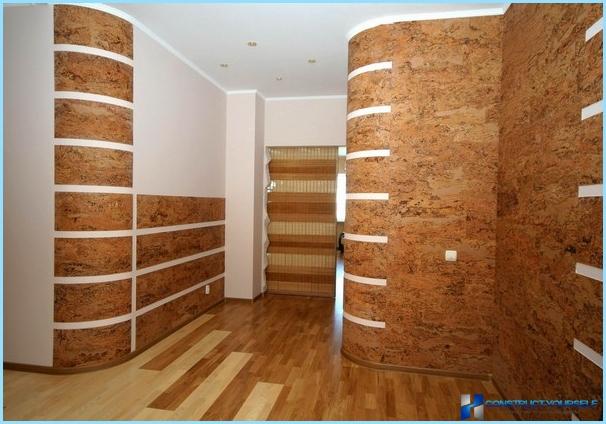

Tube ↑

Cork panels are a natural, durable and lightweight material, which significantly enhances heat and sound insulation properties of the room. Due to its cellular structure they can become a real decoration for any hallway or hallway.

Finish corridor wall panels with their hands ↑

Methods of attachment of the wall panels depends on the material of their manufacture and the quality of the walls:

- Panels made of MDF and fiberboard due to its small weight can be mounted directly on the wall with glue (but only if the wall is perfectly flat). The zigzag adhesive is applied to the entire surface of the panel, then gently pressed her to the wall. The glue should be elastic and not interfere with the thermal expansion panel.

- As an additional method to mechanical fastening can be used for bonding the panels to the sheathing. As the main this method will not work, as it’s not too reliable.

- One of the most reliable ways of fastening the panel to the sheathing is fastening with screws. However, this method can be applied only in those areas in which there are no sudden temperature drops and high humidity. The reason is that the screws prevent the extension panels in the process of raising temperature and humidity, which leads to deformation of the material.

- Another popular method is to mount the panels to the purlins by means of Kleimenov. In this case, the deformation of the panels are not facing, so this mounting method can be used for any room.

Before you start decorating, you need to calculate the right amount of finishing material. In the shop helped me decide on the right amount, the sales assistant just need to call the height and length of walls.