One of the conditions for proper growth and development of plants is timely watering. But not always because of the employment of the owners and the remoteness of the site from the city are able to provide. To solve the problem of creating optimal conditions for compliance with the humidity conditions will help set the timer. This device does not only simplify the maintenance of the green «Pets», but also have a beneficial effect on the quality of the crop. Need in the household appliance can be purchased at gardening store or you can make a watering timer with his hands. How to choose the optimal variant of the model or make a simple device to independently consider the article.

The contents

The watering timer is a single or multi-channel locking mechanism, managing water pump. It opens periodically, allowing the water to enter the watering system.

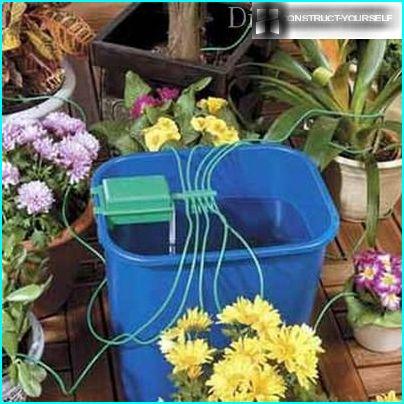

Drip irrigation systems provide the ability for a few days or even weeks to appear on the site without worrying for your seedlings

Timer automatic watering in one fell swoop solves a lot of problems:

- Provides watering with a predetermined intensity and frequency;

- Prevents waterlogged soil and root rot due to the steady and slow water flow;

- Feeding water from the roots of vegetable crops, solves the problem of sunburn of the leaves and minimizes the risk of disease;

- Providing local irrigation, helps to resolve the issue with the weeds.

For ease of maintenance timers water flow place, together with other equipment in plastic boxes that are installed under the ground.

To have the ability to quickly access devices, such boxes are equipped with a removable hatch or a tight-fitting lid

Principal of such devices

According to the principle of countdown timers are divided into the device a single action (in case of a single actuation) and multiple (when preset exposures triggers multiple times).

Depending on the type of mechanism the timer is:

- Electronic the control unit includes an electronic apparatus, which determines the response time and opening the electromagnetic valve. The undeniable advantage of this type of devices is the wide range of time delay that can vary from as short as 30 seconds and up to one week. The watering can be adjusted on site or remotely.

- Mechanical – a control unit, equipped with a spiral spring and a mechanical valve. Works on the principle of a mechanical watch. One cycle of a plant the spring unit is able to provide uninterrupted work of the mechanism to 24 hours, opening the valve on the user-defined period of operation. Irrigation mode is adjusted manually only.

Both devices are multi-channel design. Mechanical watering timer has simple design and lack of lead-in wires. It significantly reduces the cost of the device.

The mechanical timer is compared with the digital counterpart has a more limited duration of a given cycle

Mechanical timer, it is sufficient to set cyclical irrigation, by choosing the interval. With the electronic model somewhat more complicated: you must first set the date and time, and after that choose the best for growing crops program.

Many have noticed that in the water supply systems of country towns at daytime due to intensive water abstraction reduced pressure. Installing automatic sprinkler timer, you can apply irrigation at evening and night time hours.

Depending on the modification of the device timers can be internal or external «normal» pipe threads, and is also equipped with quick-connectors or hose connectors quick connect irrigation system.

The most expensive models have additional functions, for example, determine the moisture content, depending on which watering is automatically reduced or extended

The options for making water timer

Planning to build on a plot automatic irrigation system for control valves is convenient to use water timers. With their help, the water supply system can be made completely non-volatile, avoiding the use of any electronics.

Design #1 — timer with a drip-wick

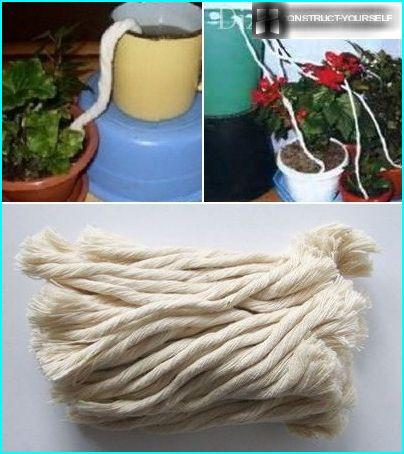

Fiber wick, capitivate moisture, raise it up to a certain height, not allowing the water to evaporate quickly. If the wick is to throw overboard the vessel, the absorbed water will start to drip from the free end.

The basis of this method are the laws of physics that create the capillary effect. It occurs when lowering a fabric wick in a container of water

The throughput of the moisture can be adjusted by adjusting the thickness of the wick, the density of twisting strands and pinch them with a wire loop.

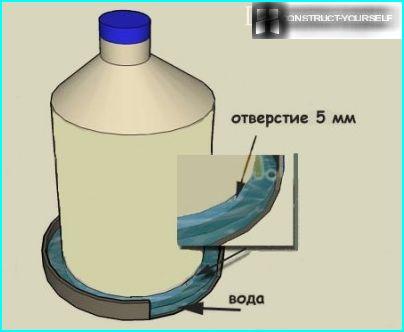

For the arrangement of the timer in a container with low sides, with a maximum height of 5-8 cm, set five or ten-litre plastic bottle. One of the key things is keeping the level of liquid in the container at a constant height. The optimal ratio of capacities is easiest to determine experimentally.

The determining factor in his work is the water column. Therefore, the height of the bottle and the depth of the wide capacity – related things

In the bottom of the bottle make a small hole for the water flow. A bottle filled with water, at the time of closing the drain hole, and is hermetically closed with the lid. The filled bottle is installed in the trough. Percolating through the bottom water will gradually leak out, stopping at the level where the hole is hidden under a layer. As the flow of water flowing from bottle water to make up the loss.

The wick is the easiest way to make a rope of suitable thickness or harness, twisted piece of fabric. It is placed in the tank correctly distributed all

The main advantage of this timer is that due to the same water level in a broad tank in the event of rain, the hydration of the bottle will be suspended.

Craftsmen, already tested in practice such a device, saying that a five-liter bottle at a flow rate of 1 drop/2 seconds is enough for 20 hours of continuous operation. Selecting the best size of bottle that performs the function of a water column, and adjusting the intensity drops, it is possible to achieve the effect of multiple delays.

Design #2 — the device regulating ball valve

In the water the timer activation time is carried out under the action of Cappel. Arising from the vessel that perform the function of ballast water reduces the weight of the structure. At some point, the weight capacity is no longer enough to hold the handle of the stopcock and the water supply starts.

For the arrangement of the water timer you need:

- The water barrel;

- Ball valve;

- Two plywood or metal circle;

- Cans or 5 liter plastic bottles;

- Construction adhesive;

- Spool of sewing threads.

For the smooth functioning of system ball valve, it is desirable to modify, attach to pinned by means of a screw handle small pulley — rocker. This will allow you to bring the valve from a closed position to an open position by tilting handle.

A pulley constructed of two identical plywood circle, gluing them planes between a construction adhesive or metal, connecting them by bolts. On the pulley wind the durable cord, for reliability, making around it a few turns. By constructing the lever segments of the cord is firmly fixed at its edges. To the free ends of the cord on opposite sides of the cargo tie – ballast and compensating the weight of a container of water. The weight of the load must be such that under the weight of the crane came to the state of the lever.

As cargo ballast and compensating the weight of the water tank is convenient to use five-liter plastic bottles

To adjust the weight of containers is easiest by podsypanina of sand in one of them and podlivaya of water to another. The role of the weighting agent may also act as metal chips or lead shot.

A container of water and will function as a timer. For this purpose in its bottom with a thin needle make a tiny hole, through which, drop by drop, and water will filter. Time leakage will depend on the volume of the bottle itself and the size of the hole. It can be from several hours to three to four days.

To cause the device to, the capacity for irrigation is set on a flat surface and fill with water. The bottles are suspended by the ends of the cord to the pulley, also fill one with sand, another with water. When equal weight of the filled bottle valve is closed.

As the excavation of the water, the capacity of losing weight. At some point the cargo, ballast, outweighing the partially emptied bottle, turn the valve to the on position «open», thereby triggering watering

There are times when you need to fully opening the valve, bypassing the intermediate position, the so – called effect of a switch. In these cases a little trick: in the closed position of the valve to the weight strapped to the edge of the thread that will perform the function of a fuse, and the free end is fixed to the tap. In the closed position of the mechanism the thread will not feel any load. As emptying water containers cargo will outweigh, but thread safety will take the extra weight, not allowing the ballast transfer valve to the on position «open». The thread breaks only when significant superiority of the cargo, instantly switching valve and allowing safe passage of water.

To bring the system to its original state simply to take a load off or to lock it in limbo, eliminating the tension of the cord.

The system is ready for operation, it only remains, before leaving the barrel to fill watering and the water timer and mount the ballast, podstrahovat his thin thread. This device is simple to manufacture and convenient to maintain. Its only disadvantage is a one-time operation.

Other ideas for creating mechanical timers can be gleaned on the thematic forms. For example, in working on the timer, some craftsmen are using a cylindrical plunger with plastic pellets in oil. The device is set up so that when the temperature is lowered at night, the displacer was involved, and weakened the spring to open the valve. To limit water consumption, use aperture. In the afternoon heated the sun’s rays plastic granules increase in size, pushing the plunger to its original position and thereby blocking the flow of water.

Design #3 — electronic timer

Craftsmen, possessing some basic knowledge of electronics can build a simple model of the electronic timer. Manual manufacture of the device presented in this video clip: