Among the useful things stored in the back of the economic owners of suburban areas, you can always find fixtures and devices for cutting wood. This can be a jig saw, hand saw, handy power saw or a power unit operating on liquid fuel. Any of «assistants» requires certain skills and attentive care. For example, the owners of the tool that runs on electricity, you need to know what are chains for power saws, is it difficult to change them yourself and if the file for proper sharpening.

The contents

Logging in large volumes or major construction work on the street will require purchase of a more powerful tool – the chainsaw. However, if you occasionally need to fix a fence, repair a house or to saw a few logs, the ideal tool is a saw. It is convenient to use in confined spaces – inside a house, in the barn or the back, as well as on the site, if the nearby power supply.

What other advantages does the tool supply? It does not require time for preparation of the fuel mixture and cuts more accurately than gasoline counterparts. Minus one – sparing regimen use. Will have to get used to the interval sawing wood. This means that after 40 seconds of work for a saw required «respite» about 20 seconds.

So, if you are already a happy owner of ergonomic, comfortable shave, get ready for what will have to get acquainted with the device, replacement and sharpening of the chain is the main dynamic details.

Before selecting herbicides, check the information about the system overheating protection. The service life of the protected motor is much longer and performance higher

How to choose the right chain?

Circuit along with the engine is a major functional item, so is in active use, often beyond repair, sharpening or replacement. Old, worn out chain it is better to replace completely, and for this it is necessary to know some rules of selection:

- When replacing any spare parts (sprockets, tires or chains) need to remember about the compatibility of the elements of power saws, that is, to acquire parts only of the manufacturer: for example, for power saws Makita chain requires the production company Makita .

- Pick up the chain depending on the purpose. If you need more power, cheaper to buy the product with a pitch of 3/8 inch, at low loads enough of 0.325 inches. The volume of the cylinder in this case is not important.

- Note the angle – this will be useful for future maintenance, repair or restoration. For greater performance, choose the angle of 30? — it is easier to perceive large load. However, when complex processing of wood (if it is raw or frozen) to stop for indicator 10?.

- Chain length must match the size of the tire. In the process, it can stretch out, SAG, but the issue is solved by simply removing 1-2 links.

Of course, you must consider the method and material cutting. For example, a longitudinal cut is better to choose a chain with a small angle. The performance will be less, but the service life will increase noticeably.

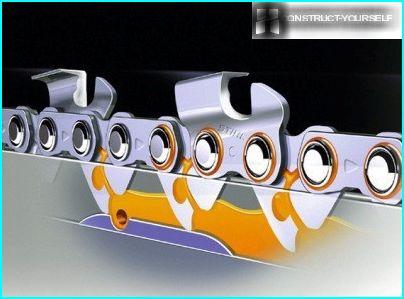

One of the indicators of the selection circuit, a step that is generally measured in inches. Is the spacing of rivets, divided by two. There is now a common notation and a common standards – 3/8, 0,325 and 0,404 inches

The parameters of the teeth of the chain

The elements of the chain – teeth – have differences that are important to consider, when purchasing a chain for those or other works.

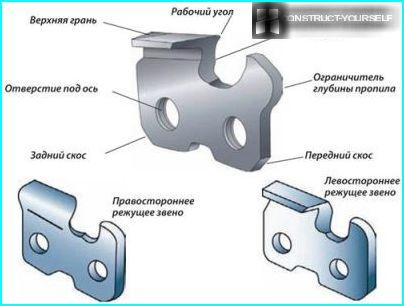

Each part of the tooth has its purpose. For example, the top face of the tooth, often called the blade tapers at the rear and forms an angle end of the blade. It is necessary to trim the chips

The sliding surface and the bevel face of the blade form a angle having a range of options from 60? up to 85?. Adjust the angle of the upper blade as the cutting angle in the sharpening process. Each of the elements, in particular, its value and degree of severity, affect the cutting ability of the saws.

To adjust the angles of inclination at an arbitrary parameters is impossible, there are proven standards that must be followed depending on the type of circuit and its functional purpose.

The angle of the blades determines the optimal cutting properties when cutting chain into the wood layer. The inner side is the angle of sharpening — 10? or 30?, if needed, you can change

The value of the rear angle is 50? or 60?. This is the most important angle, but to measure it rather difficult and complicated to adjust, if you do not follow the rest of the values.

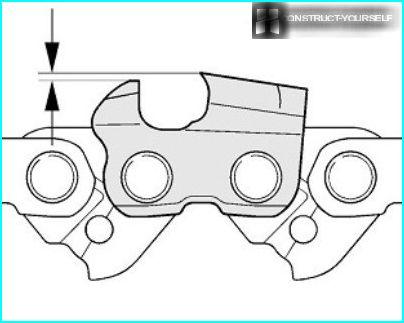

The distance of the depth limiter affects how thick it will chip. It depends on the type and purpose of the circuit and is equal to 0,6-0,8 mm. the Limiter requires adjustment and grinds, but less so in 5-8 shanks

Self-replacement cutting chain

Companies producing electric saws and do not forbid to replace the chain with their hands, on the contrary, it often happens that the new products complement the instructions for the repair and replacement of individual parts. You should start with buying a new chain.

Check the chain for compliance, that is, study her features: the length (depends on tyres), the step size (relative to stars), the thickness of the drive link

One of the common designs budget peel with side tension. To change the circuit, completed the following steps:

- move the shield while lowering the brake;

- with a screwdriver turn the tension control screw, Unscrew the nut, thereby to weaken the tension;

- remove the cover;

- detachable tire chain from the sprocket;

- remove the old chain from the tire, install in its place a new;

- actions in reverse order.

Pull the chain smoothly, without jerks. Finally pulled her after closing the plastic cover using the screws and nuts.

There are modern system Keyless-tensioning chains, but many artists prefer the traditional side stretch, is somewhat problematic, but checked and reliable

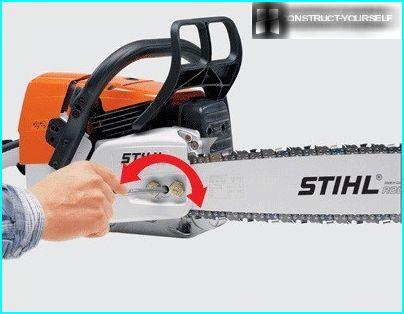

Current models of power saws are the so-called wing nuts are applied to the chain tension. Thanks to this element, the replacement process is faster – and this is important when large volumes of work. Lowering the brake, Unscrew the nut and remove the cover. Gently pushing back the tire, remove the old chain, put on new – first the star, then along the entire length. Then install the sprocket in place, tighten the nut. Turn the tension wheel in the housing direction and finally tighten «lamb».

The last stage of checking chain tension. It should fit snugly to the tire when the brake is released, but scroll under manual exposure. For more efficient check is recommended to run the saw at low speed

For more information about the stretch of the chain you can see in the video:

Technology right stockt

It is naive to think that the saw will always run like the day of purchase. Wood, even pliable and soft, fine solid material, causing a gradual dulling of the cutting surfaces. After a certain period, which depends largely on the activity of using the tool and the quality of wood, the chain will become dull and will need sharpening. If time does not sharpen the teeth, they lose their form will be ruined and will need no repairs, and complete replacement – as is economically disadvantageous.

Don’t miss a moment!

Certain intervals don’t exist. Usually sharpening is required, when they begin to show signs of bluntness. One of the main features – change size and appearance of the chips. Due to violations of the sharp cutting edge of the teeth, it becomes smaller and darker than usual, and sometimes like dust.

An experienced master can determine whether sharpening is not characteristic of sawdust and acetone. In the process of cutting appears unusual vibration that could cause the destruction of the sprocket and wear of important parts

If you suspect, inspect the chain. On the sharp pieces should not be chipping, radius, damage, and form the cutting edge must remain original. If you notice the slightest irregularities in the configuration of the teeth of the chain needs sharpening.

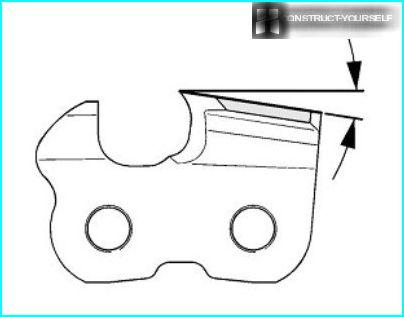

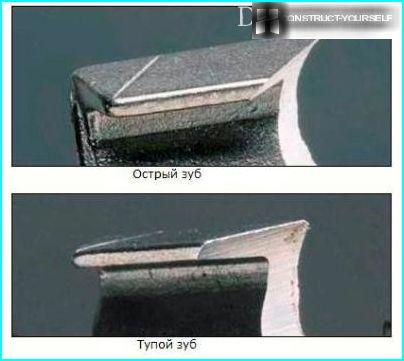

Stupid tooth cutting edge is worn down in two directions: in front of the blade and the line side of the cut. During sharpening it is necessary to correct the form of the whole cutting part

Advice from the professionals?

Residents of large cities are faced with a choice: it is possible to sharpen chain saws service center or sharpening alone, with the help of special tools. Owners of power tools from small towns and villages do not have this possibility, therefore, despite the complexity of the process, it is better to learn how to repair the chain with their hands. But the self-sharpening is a plus – saving money.

The cost of sharpening one tooth with the editing limiter will cost 100-120 rubles, but most service centers place orders only with a minimum amount of 5000 rubles or more (calculated by the number of teeth of the chain)

Advantage professional-sharpening – high quality work. Chain off the tire, pull on a special machine, set the sharpening angle and alternately ruled by each tooth. The sharpening precision is defined in tenths of a millimeter.

Can I sharpen the chain with a file?

Many master craftsmen are doing just that – when the first symptoms of blunting of the links we take the file and correct the angle of the cutting edge. However, any tool will not work, you should have a special set that includes at least four essential tools:

- a flat file for adjusting depth gauge;

- round file with guide lines;

- caliber;

- bar to determine the angle.

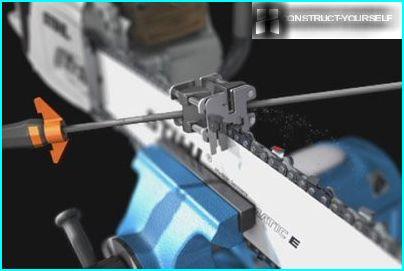

For sharpening the chain is left on the tire, and the tire is clamped in a Vice. The file should conform to the teeth by the diameter.

Tool for manual sharpening of chain saws can be purchased in the supermarket building, the average cost of one set from 300 to 900 rubles

If you are using a round file make sure that it is only 1/5 protrude above ground part. The first tooth is recommended to mark, accidentally wrap around. The movement should be rhythmic and precise, not piecemeal, but in one direction only.

After a few shanks to handle and the limiter, which over time loses its shape. Caliber applied to the edge face side to the limiter. If the limiter is noticeably beyond the boundaries of the caliber, it should be trim with a flat file. The position of the tool perpendicular to the tire.

During sharpening follow the movement of the file which should be located at an angle of 90? in relation to the bus. Try to remember the amplitude and number of movements to all teeth of the chain have been sharpened equally

Teeth chains wear unevenly, so you will be faced with the fact that they have different heights. In this case, you should find the most worn item and focus on it

The quality of the work on the eyes not to determine it will be known only after a trial cut.

Proper sharpening on the machine

Constantly use a file to correct cutting edge is impossible, as the inaccuracy and uneven stitching leads to a rapid chain wear. Even if you have an arm, and the sharpening process seems quick and easy (and it takes 6 to 8 hours), try using the machine more effective device.

All machines for sharpening chains are divided into manual and electric. Hand tools – basic design, resembling a frame or a jig saw. For manual operations it is necessary to firmly secure the tire with the chain (to remove with a saw is not needed) in a vise, and then alternately processing each tooth. Compactness, light weight and ease of transportation make it easy to carry the device for long distances if the need arises.

Manual machines have simple construction and low cost – from 850 to 1700 rubles. The best manufacturers of manual grinding equipment is considered Oregon and champion

When you purchase the second option – electric models will need a power source, and this means that it is impossible to carry out the sharpening away from an outlet. But the quality of work will be much higher, in addition, electrotank have a set of useful features:

- work with different types of circuits;

- correction depth and step cut;

- the exact formation of the limiter;

- setting the desired cutting angle.

Before work is necessary to study carefully the instructions and do a test sharpening on 1 tooth. Then set the parameters according to the first tooth to all of the following items consistent with him. This ensures uniform sharpening of all teeth, thus providing good productivity and high performance.

How to extend the life of the chain?

And finally, a few tips for those who prefer to work more and less to do repair, replacement and sharpening chains. Remember that the saw is designed to work with wood, so in any case, do not use it for cutting products from other materials. Ensure that the wood was not third-party items that can spoil the teeth of the chain, for example, nails, bolts, or metal clips. Even the small steel stud can lead to disrepair a few teeth, and as a result have to replace the whole chain.

The ideal material for cutting dry wooden logs, planks or bars, the width (diameter) not exceeding the length of the bus. To cut the huge trunk into several loops, use gasoline saw industrial type

So you don’t accidentally «to screw up» the saw, use a special high stand «goats» and make sure that the tire chain is not in contact with the ground. The cut shall be done freely, without «Zakusov», if the teeth grab the wood, or the tire moves with the work – time to do the sharpening. Be sure to observe the interval mode — allow the saw to rest. Time to lubricate the mechanism and make sure it was not overheating. Adherence to a few simple rules will increase the service life of the saws and will allow to realize a lot of interesting plans.