Country construction and repair can not do without the use of a chainsaw, and garden maintenance. Due to a malfunction of the tool can get all the work, so it is important to be able to take it apart to find the issue and fix them. With sufficient experience and skill, is possible even adjusting the carburetor of a chainsaw is a difficult procedure, and more specifically, jewellery. How to carry out procedures for adjustment, we offer you today to disassemble.

The contents

The device carburetor chainsaw

No repair can do without knowledge of the basics of the device mechanism. Understanding the constituent elements and working principle, it is easier to determine the cause of failure.

Any malfunction in the carburetor threatens to stop the engine

The carburetor is one of the main functional parts of the engine, which serves for the preparation and supply of fuel mixture, consisting of specific proportions of fuel and air. As soon as the proportion of violated – the engine starts «to act up», and then stops working.

To achieve proper operation of the carburetor can be found by examining it «stuffing»:

- Tube with transverse damper to adjust air flow.

- Diffuser – contraction to increase the flow rate of air, is near the inlet of the fuel.

- The atomizer, which feeds the fuel (the fuel needle on the diagram).

- Float chamber for regulating the fuel level when entering the channel.

Here’s how it looks on the diagram:

The diagram shows the interaction of the fuel and air flow

Working principle: the air stream in the diffuser sprays the fuel, creating a mixture that enters the cylinder. The greater the number of the incoming fuel, the higher engine speed. Carburetors various models work on the same scheme.

When all the necessary adjustment?

Specifically, adjusting the carburetor of a chainsaw is required in rare cases are more likely to have problems associated with the supply of fuel or wear and tear. But sometimes «symptoms» indicate that it is necessary to adjust the mechanism. Here are some signs:

- After the engine starts, it immediately stalls. As an option – do not start. The reason lies in the overabundance of air and the fuel shortage.

- The increase in fuel consumption, and as a result a large amount of exhaust gases. This is due to the reverse process — the saturation of the mixture of fuel.

Reasons for failure of adjustment may be mechanical:

- Due to the strong vibration damaged the protective cover, as a result, all three bolts are losing the installed fixation.

- Due to wear of the piston of the engine. In this case, the adjusting the carburetor of a chainsaw will help only for a while, it is better to replace worn-out part.

- The cause of the blockage, which occurs due to poor quality fuel, slag or filter damage. Carburetor requires complete disassembly, cleaning and adjustment.

If the chainsaw suddenly stopped working to clarify the reasons you need to disassemble it

Step-by-step instructions for the disassembly

The device of the carburettor models from different brands is almost identical, so take for example the chainsaw Partner. Each element is carefully removed and stacked in order to make it easier to collect.

The carburetors of chainsaws from different manufacturers if they are different, does not matter

The top cover is removed by unscrewing three bolts. Then the foam composite air filter.

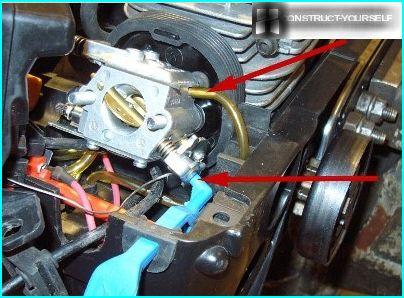

The arrows indicate the bolts that need to Unscrew to remove the cover

Then remove the fuel hose behind him – thrust actuator.

The upper arrow points to the fuel hose, bottom — for traction drive

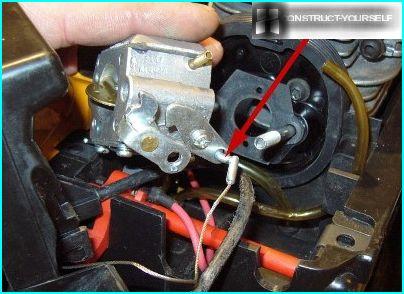

Next you should remove the tip of the cable.

The arrow shows the tip of a rope that must be removed

Left the bleeder contractible petrol hose.

Also gently remove the petrol hose that the arrow is pointing

Carb completely detachable, it is ready for adjustment. Its mechanism is quite complicated, so if you want to further disassemble the carb, remove the items very carefully – they are small so can get lost.

The carburetor consists of many small parts which when disassembling should be expanded in order

Features settings and adjustments

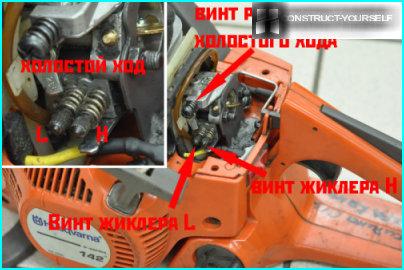

To learn how to adjust the carburetor on the chainsaw, you should learn to distinguish the three screws (some models have only one).

The screws L and H are similar only in appearance, they are actually different

Each screw has its own letter designation:

- «L» configures the low speed;

- «H» necessary to adjust the top speed;

- «T» need to adjust idle (for models with a single screw is present only).

Factory setting is optimal, and with the screws set engine operation in special situations (work, associated with different climatic conditions).

In the diagram, one may see the adjustment screws of the carburetor when the cover is closed

To configure chainsaw using special tool

Setting is performed only by the screws L and N. To increase the speed, turn them clockwise. To lower – counterclockwise. The sequence of the screws: L – N – T. If there is any doubt about the adjustment, it is better to consult a specialist, as incorrect configuration can bring the engine down.