It would seem, why the chainsaw vacationers, which is engaged in cultivation of vegetables and fruits, or the owner of a country house with a small garden and a few flower beds? The question is no longer when there is a desire to build the bathhouse, to update the greenhouse, stretch the old case or just a bench to rest. Unfortunately, any mechanism that periodically needs in the prevention and change of spare parts, and for this it is necessary to understand the structure of the product, besides repair chainsaw own hands will save time and money.

The contents

Structural components of the chainsaw

All chainsaws are similar in structure, regardless of whether they are European production (ECHO, Stihl, Husqvarna) or domestic (Cedar, Ural). Inside the case is the basic elements of the fuel tank and the engine, and the outside starter of the handle, the saw part (tire) chain. A sharp jerk of the rope starts the engine and the saw blade.

To begin with we suggest you to see the videos that show how to work the chainsaw and how it works:

From time to time in the work of saws is causing the problems, the solution of which require disassembly. What can happen with such a simple mechanism as a chainsaw? At least the following:

- Ceases to start the engine;

- It starts, but soon stops;

- Ceases to function in the cut;

- Loses power;

Most of the problems are related or interruptions in the operation of the engine (fuel supply system, exhaust system, ignition, cylinder-piston parts), or defects of other systems and components (clutch, brake, chain, tire, lubrication system). Consider the most common breakages and methods of their elimination.

Serviceable chainsaw starts with one charge, and does not fail in the cut

Check the ignition system

The first thing you need to do in case of breakage of a chain saw — inspect the spark plug by disconnecting the wire and gently unscrewing it with a special key.

The components of the ignition system chainsaws: 1 — flywheel with magnets, 2 — ignition module, 3 — candle, 4 — wire high voltage

Twisting the spark plug to check its condition

Its appearance speaks volumes:

- Dry. Most likely, the cylinder gets the fuel mixture. It’s not the ignition system so the candle twist back.

- Heavily splashed with fuel. The cause of the excess fuel mixture lies either in violation of the rules run, or to incorrect adjustment of the carburetor. Carefully wipe the candle, block the flow of fuel and include the starter to remove excess fuel and air to the combustion chamber. Then a candle is placed on the location and trigger mechanism.

- Covered with black soot. This may indicate the use of substandard oil, the carburettor incorrectly adjusted or incorrectly calculated the ratio of gasoline and oil. The candle should be rinsed, cleaned of sludge with a sharp object (awl or needle), wipe the electrodes with sandpaper and put in place.

Checking out the candle, you need to pay attention to the gap between the electrodes: normal is 0.5 to 0.65 mm. Damaged or worn gasket need to replace.

A large amount of black soot on the spark plug tells about the irregularities in the operation of the engine

To be sure, you should check the presence of spark. On the candle put the ignition wire, pliers connect the nut of the candle and the cylinder, make the starter and watch for spark. If not, the candle needs to be replaced. If the new spark does not spark – the problem is high-voltage wire or the connection with the candle.

Repair of fuel injection

The fuel may not enter the cylinder for the following reasons:

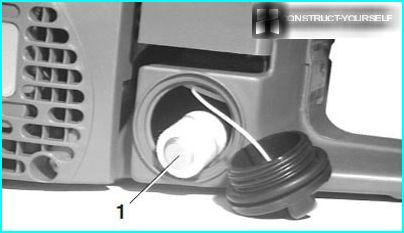

- Contaminated fuel filter. You should remove the fuel hose and check fuel is flowing. If the jet is weak, you may need to clean the filter. It comes out through the filler opening of the fuel tank and cleaned, in case of strong contamination replace new. As prophylaxis it is recommended to replace the fuel filter every three months.

- A clogged breather (holes in the lid of the fuel tank). Also check by disconnecting the hose, in case of blockage clean with a needle.

- Lack or insufficient amount of fuel. The cause of the failure can be several. The first reason is the air filter clogged. The air ceases to flow into the carb in the right quantity, in this regard due to a too rich fuel mixture disrupted motor. A dirty filter carefully removed, cleaned and washed in water, then dried and set in place.

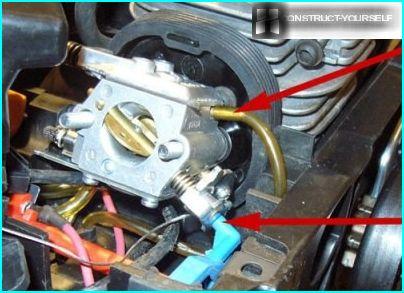

Another reason is the wrong uregulirovanii carb. The adjustment is made with three screws.

Timely replacement of the fuel filter ensures a supply of fuel

The fuel hose and the air damper should fit tightly to the fittings

The lever cable throttle actuator should be in its place

During operation, you must use the manual, otherwise you may make things worse.

Article topic: carb adjustment chainsaw: technical details

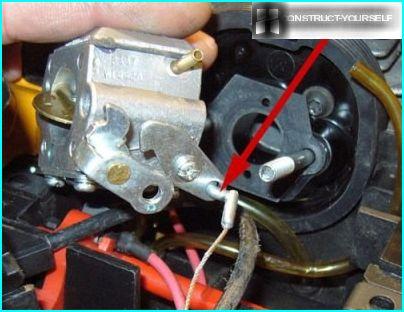

And the last reason – violation of the integrity of the membrane or clogging of the channels of the carb.

To fix the carburetor yourself, you should be familiar with all the details

All parts should be clean, dry and serviceable.

Disassembly and cleaning of the muffler

If the engine is at low speed works fine, and at large begins to stall, the reason may lie in the spark arrestor, muffler, clogged with the combustion products.

Procedure:

- remove the exhaust muffler;

- to disassemble (there are non-separable model);

- be cleaned of sludge using detergents;

- dry with a hair dryer;

- install the.

Dry cleaning not valid, because the soot contains carcinogens, inhalation of which is dangerous for health. After removing the muffler exhaust hole is closed with a clean cloth.

Interruptions in the operation of chainsaws signaled a possible clogged muffler

To prevent clogging of the muffler, it is necessary to monitor the composition of the fuel mixture. The amount of oil should not exceed the norms recommended by the manufacturer. Poor quality oil will also adversely affect engine performance.

Assessment of the status of the cylinder group

Often the engine will not start or is not running at full power due to low cylinder pressure. It can be caused by wear on the piston or cylinder, the ceasing of the piston rings, worn bearings. Partly to consider the state of the cylinder-piston group (tspg) possible by removing the muffler and looking into the opened hole.

The compression gauge placed in the plug hole will help to make a measurement of compression in the engine – the measurement, you can also talk about the state of Chu. Accurate information is obtained only after complete disassembly of the mechanism. If the piston is chipped or scratched, it needs to be replaced. The piston ring must be clean, without soot, and to be exactly in its place.

Wear of the piston and crank mechanism referred to serious problems

According to the results of measurement of compression, you can judge the condition of the parts Chu

Fix system chain lubrication

Consider the three main faults:

- The oil dripping. Should check whether the tube is hermetically attached to the nozzle of the pump and there are no cracks. Problem tube sealed with sealant or change.

- Insufficient flow of the oil. Most likely, clogged channels of supply of lubricant.

- The appearance of cracks on the housing of an oil pump. Necessary replacement parts.

Here’s how diagnosis of lubricating system:

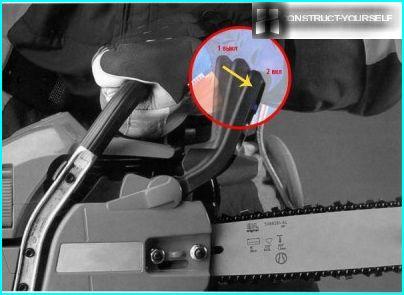

Adjustment chain brake

The chain brake is often not triggered by reason of clogging with grease or sawdust the brake band and the area under the lid. Be sure to clear all of the blockages. Maybe the tape is just worn out, then it must be replaced.

The brake circuit is restored by means of mechanical cleaning

Some parts of chainsaws wear out faster than others. These include sprocket, tyre chain, anti-vibration elements. For quick replacement parts you should always have on hand. Do not neglect and sharpening chain.