Stay outside the city, in the country of residence has the additional complexity, because not all have centralized communication. Residents of the periphery and improve the conditions of life in the cottage or cabin, so that he was no different from urban housing. One of the points of a comfortable life for the continued availability of water in sufficient quantity. In this case, the help of special equipment – pump station with his own hands. Through self-installation can save the family budget.

The contents

The device and principle of operation of the unit

The main number of wells in suburban areas has a depth of 20 m was optimal for the installation of automatic equipment. If these parameters do not need to purchase deep pump, the automatic control system or intermediate capacity: directly from the borehole (or well) water is supplied to points of analysis. To ensure the correct connection of the pumping station, you need to understand what it is and how it works.

The main functional units of the station is the following equipment:

- The pump is of centrifugal type, providing lift water and transport it to the house.

- Accumulator, hydraulic softening the blow. It consists of two parts separated by a membrane.

- Electric motor connected to the pressure switch and pump.

- Pressure switch, controlling the level in the system. If the pressure falls below a certain parameter, it starts the engine, if there is excess pressure off.

- Pressure gauge – a device for determining the pressure. With it, make adjustments.

- The system of water intake, with non-return valve (in the well).

- Thoroughfare connecting the water intake and pump.

Using this formula, we can determine the maximum suction depth: the diagram shows clearly which measurements you need to do

The most common variant of the pumping station with accumulator is mounted to the top surface of the pump and the node, including pressure gauge, pressure switch and dry run protection

As can be seen from the table, cost of pumping stations may be different. It depends on the power, maximum pressure, capacity, manufacturer

Before the installation of pumping equipment you need to buy all of the functional parts according to the parameters of the well and water system.

Separate installation of pump station

The determination of the place of installation

At first sight, places for the installation of the equipment pretty much is any free area in the house or outside. It turns out all different. However, only well-thought-out installation of a pumping station ensures complete her work, so you need to meet certain conditions.

Installation conditions:

- the proximity to the borehole or well provides a stable the absorption of water;

- the room should be warm, dry and ventilated;

- placement should not be difficult, as the required maintenance and repair work;

- the room should hide the noise, which makes pumping equipment.

One of the variants of installation of pump station on a specially attached to the wall shelf. Space for installation is boiler room, boiler room or utility room

It is difficult to comply with all the conditions, but it is advisable to adhere to at least some. So, let’s look at a few suitable places for installation.

Option #1 — the premises inside the house

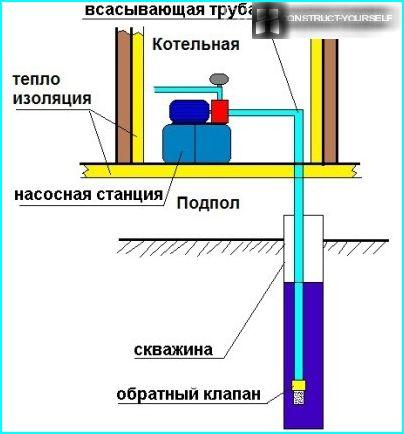

A well insulated boiler room on site – ideal area for installation in the case of permanent residence. The main drawback is good audibility in the low-quality noise insulation.

If the pump station is located in a separate room suburban home, well it is best to arrange directly under the building

Option #2 — basement

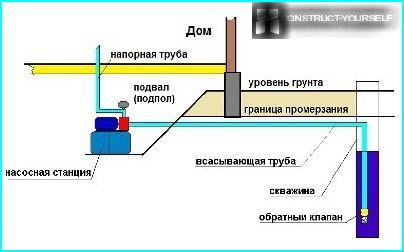

The cellar or basement can be equipped for the installation of a pump station, but it is important to consider when designing. If the room has no heating and the floors and walls aren’t insulated, you will have to spend a lot of effort to prepare it.

A well furnished basement great for installation of pump station. During the laying of the pipeline in the Foundation of the house should make the hole for communication

Option #3 — special well

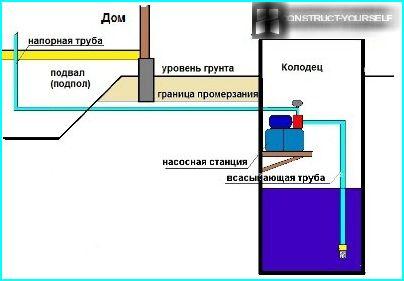

The variant with a couple of pitfalls. First, the difficulty of maintaining the desired level of pressure in the house, the second – the difficulty of the repair work.

When the location of the pumping station in the well, on the Playground, you should adjust the level of pressure that depends on the hardware capacity and settings of the pressure tube

Option #4 — caisson

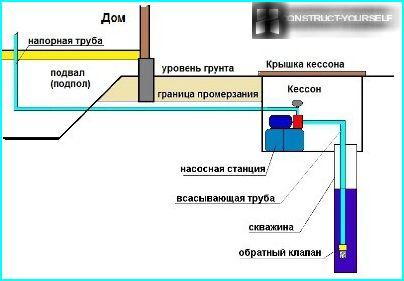

A special area near the outlet hole is also suitable for mounting, the main thing – correctly to calculate depth of its location. The required temperature will create a warm land.

Pumping station, located in the caisson wells has two advantages: a full noise insulation and protection from freezing during cold weather

In the absence of seats specially designed set units in common areas (hallway, bathroom, hallway, kitchen), but this is an extreme option. The loud noise of the station and a comfortable stay – concepts incompatible, so for the installation of a pumping station in the country to prepare a separate room.

The pipeline

Well, usually located near the house. To the pumping station worked fine and without interruption, it is necessary to ensure the smooth flow of water from the source to the equipment, which is located in a designated area. With this purpose, pipeline.

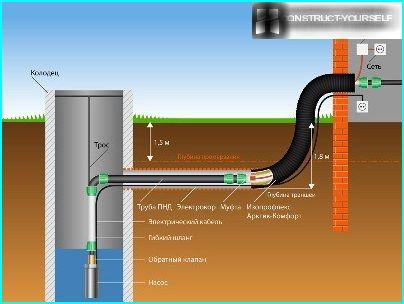

Low winter temperatures may cause freezing pipes, so they are buried in the ground, preferably to a depth which is below the level of soil freezing. Otherwise, should produce a warming of the highway. Work are as follows:

- digging a trench with a slight slope towards the well;

- the device in the Foundation holes for the pipes at the optimum height (if necessary);

- laying of pipes;

- connecting pipe for pumping equipment.

During the arrangement of the trunk can be faced with such a problem, as the presence of high standing surface water. The pipe in this case is mounted above a critical level, and for protection from the cold use a heat insulating material or the heating cable.

Advantages of polyethylene pipes and fittings to the metal analogues: absence of corrosion, ease of installation and repair, low price (30-40 RUB/p. m)

The scheme of installation of the pumping station shows an embodiment of insulation of pipes above the level of soil freezing

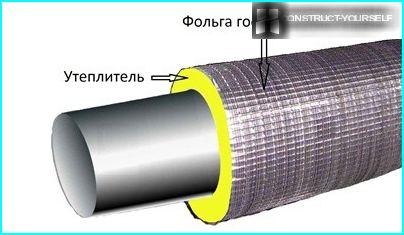

The best option for insulation of the outside water pipes is solid «shell» of polystyrene (thickness 8 cm), wrapped in foil

For thermal insulation of pipes, which are laid above the level of soil freezing, often use inexpensive and environmentally friendly material — mineral wool on basalt basis.

Outdoor work

On the external side of polypropylene pipe fixed in the metal mesh, which will serve as a strainer. In addition, you will need a check valve to ensure the stable filling the pipe with water.

It is possible to purchase ready-made hose with non-return valve and strainer, but is equipped with his own hands will be much cheaper

Without this part the pipe will be empty hence the pump will not pump water. Valve fix using the coupling with external thread. So fitted the end of a pipe placed in the borehole.

Strainer for inlet hose is a metal mesh with a small cell. Without him the correct operation of the pumping station impossible

After performing these steps, you can do ennoblement of headroom well.

The connection of the equipment

So, how to properly connect the home pumping station, to continue not to deal with technical inconsistencies? First set the unit on a specially prepared base. It can be brick, concrete or wood. To ensure stability, screw the legs of the station with the help of anchor bolts.

For installation of the pumping station, there are special leg-stand, however, to impart additional stability to the equipment to be fixed with bolts

If the equipment to put the rubber Mat, it is possible to suppress unnecessary vibration.

For more convenient service pumping station set on the basis of the height of an ordinary table, made of durable material — concrete, brick

The next step is connecting the pipe coming from the well. Most often it is a plastic product with a diameter of 32 mm. For connection, you need a coupler with external thread (1 inch) metal area with external thread (1 inch), non-return valve with the same diameter, a direct faucet «American». All the parts being joined: pipe fasten coupling, «American» fix with a thread.

One of the check valves is in the bore, and the second is mounted directly to the pump station. Both valves serve to protect the system from water hammer and ensure the correct direction of water movement

The second output is intended for communication with the water network. It is usually located at the top of the equipment. Connection pipe is also made of polyethylene, as it is a cheap, plastic, durable material. Fixation occurs in a similar way – using «American women» and the combined clutch (1 inch, 90° angle) with an external thread. First «American» to fasten the exit of the station, then tap mounted clutch from propylene, at last fix a water pipe in the coupling method adhesions.

For full sealing must seal. Traditionally used a coil of flax, on top of it apply a special sealing paste

After you have connected the pumping station to the water intake and water supply, it is necessary to check the quality of its work.

Conduct a trial run

Before starting station must be filled with water. Through the plug hole, let the water so that it filled the pressure tank, line and pump. Open the valves and turn on the power supply. The engine starts and the water begins to fill the pressure tube until all air are removed. Pressure will rise until the required value is 1.5-3 ATM, then the equipment is automatically switched off.

In some cases it is necessary to adjust the pressure. With this purpose, remove the cover from the relay and tighten the nut

As you can see, installing a home pumping station with his own hands is easy, the main thing – to comply with the installation instructions.