Potatoes are one of the most popular crops which are grown not only for us, but also in many Eastern European countries. For over three hundred year history of growing potatoes was created agronomic technology, which tried to facilitate the cultivation of culture and increase its productivity. If industrial scale cultivation of potatoes today for the hilling of the plants used tractors with interchangeable attachments, cultivators, on private land you can use Hiller made for walking tractor.

The contents

Various models of Hillers

Hiller is the second most important tool after a plow and winch. It can be first cut into furrows for planting, and subsequently fill them with seed.

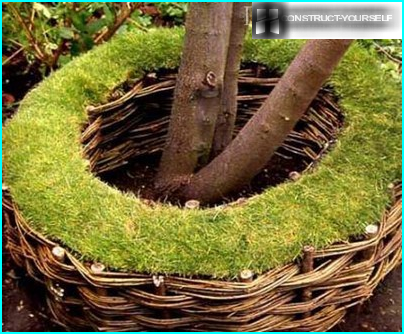

Spending Hiller on the rows of evenly planted rows of potatoes can be seen as the wings of the tool quickly spiked soil in the hole with the tubers

In the market you can find several model variants of this tool.

Option #1 — listary Hiller

This is the easiest type of instrument that has a fixed width. The design represents two connected and moved apart a little fixed wing. Since the wings of the tool is fixed, you cannot adjust the width, adjusting the mouldboard to the width of the aisles. Therefore, when working with this tool aisle adapt to the capabilities of the Hiller, not Vice versa. Traditionally, manufacturers produce products with a width of 25-30 cm, which is also not the most convenient option, because the technology of growing potatoes provides for row spacing of 50-60 cm.

These tools are designed to work with the cultivators, the power of which does not exceed 3.5 HP and the total weight of the unit is 25-30 kg

The design feature of Lusternik Hillers is also the presence of thin struts, which prevent the overload of the cultivator when the depth of the mouldboard in dense layers of the soil.

Some models listerner Hillers are streamlined, that is more preferable, because when working with such a tool less flips and issuepedia soil.

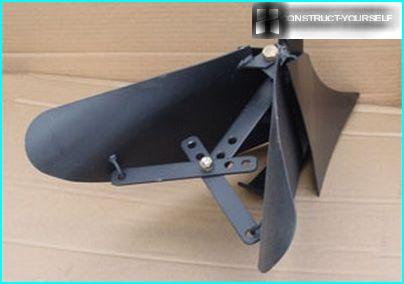

Option #2 — products with variable widths

Such tools are more convenient, because equipped with adjustment mechanism, through which you can change the position of the wings. This allows you to adjust the tool under different row spacing.

These Hillers are designed to work with a more powerful tillers with motors from 4, 0 HP more, weighing more than 30 kg

A significant drawback of such designs is their large power consumption. The reason for this is that in the process the wings of the tool push the soil to the side, part of which after passing it all crumbles back into the furrow. As a result, the back and arms get tired more quickly, and part of engine power is spent on useless work. But despite this they are one of the most popular models among the majority of gardeners.

Option #3 — disc models

The disk Hillers are much more expensive than their traditional counterparts, but the efficiency of such tools in times more

The main advantages of disk Hillers are:

- A good combination of power tillers by tool. Using disk Hiller, by lowering the speed of the welder increases its power. This not only improves the efficiency of cultivation, but also positively affects the operation of the machine.

- Ease of use. To operate this tool need to exert minimum effort: he himself pushes itself forward, without requiring an additional push in the back.

- Versatility. With this tool hilling can be done after planting of the tubers and the period of active growth of the aerial parts of the crops.

Choosing among the variety of assortment, it is desirable to give preference to models, made of alloy steel, is equipped with ball bearings (not bushings slide), with large diameter and thick disks.

Option #4 — Hillers propeller type

The principle of the tool is in the special propellers, under the action of which first the soil is crushed and combed weeds and loose soil asociada beds

These Hillers are designed for arrangement of tillers and cultivators, which have two front gears. This is necessary in order to second gear with a boost of power and 180 rpm, using the tool you can not only loosen, but also to throw the soil in the beds between rows.

An example of self-production osternohe Hiller

As can be seen, the Hillers are a fairly simple design. To make a mouldboard for tillers, there is nothing difficult.

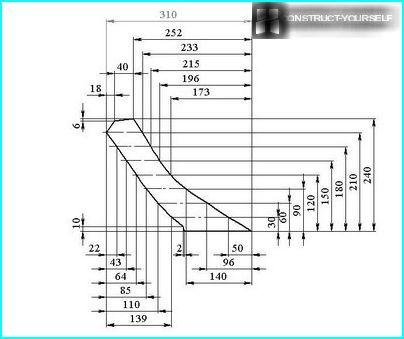

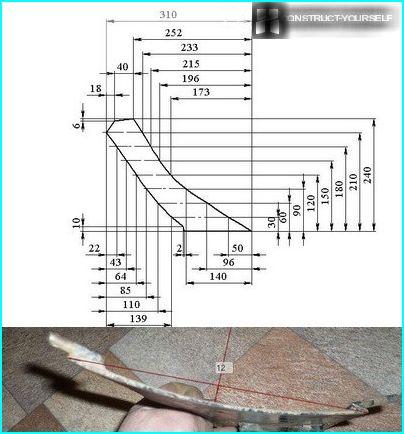

To create a traditional unregulated Hiller is necessary to pattern metal thickness of 2 mm cut halves of the product

These halves should bend to match the radius, and then cook for 2-3 passes. The welds should be treated with a grinder, and if necessary, selectively podarit and re-cleaned. The result is a perfect uniform layer of metal.

The wings of the tool are also cut from metal with a thickness of 2 mm and bonded on the same principle

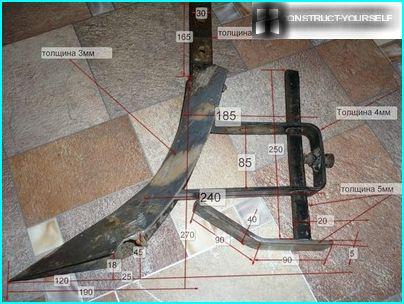

In the result, should get here this design. For clarity, shows the thickness of the elements and all the dimensions of the base of the tool

A simple model of a disk Hiller to the tillers

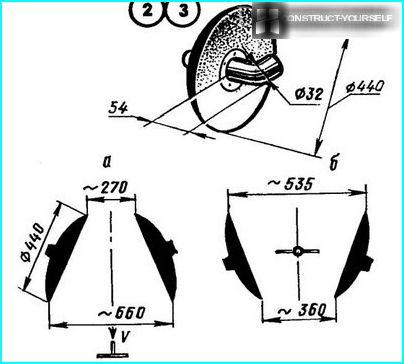

For the manufacture of tools is necessary to choose the type of wings. Discs, tines or blades, are steel sheets with thickness 1.5-2 mm, with recurved bottom edge.

Important: drives must be strictly symmetrical. Otherwise, the design will be «news» that will greatly hinder the work.

When building a design, you can use the shears taken from the old planter.

Tines set at an angle, keeping the distance between the bottom points corresponding to the width of the wheel track is the width between the rows

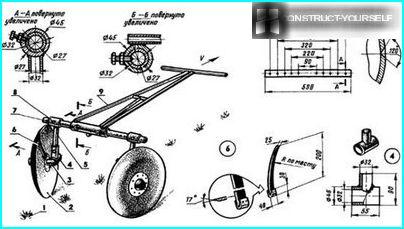

Connect the elements together using a bolt connection or by welding. Drives themselves connect by using the adjustable adapter. In addition to the discs, the main elements of the tool are: T-shaped leash, screw turnbuckle and stands. Lanyards are required for regulation along the vertical axis of rotation of the discs. To the cultivator tool is attached with beams with wings.

In the manufacture and Assembly of parts based on the drawing it is important to consider the ratio of the size and design of the attachment. There are two possible the manufacture of tools: fixed or variable width of the wings. In the second method of arrangement the distance between the discs can be changed by a symmetric permutation stands.

The main elements of Assembly: 1 – a number of processed, 2 – disc, 3 – a fist 4 – a T-shaped bracket, 5 – stand, 6 – steel scraper, 7 – axle, 8 – bolt, 9 – arm, the beam

To facilitate the work with the tool you need to include the arrangement of bearings. Installing bearings, not sliding bushing, it is possible to improve the reliability of the product.

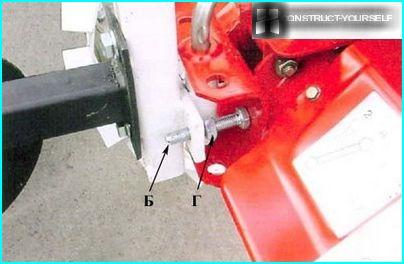

In the Assembly process of the structure for attaching the tool to the cultivator engages the bracket coupling without beam. To this end, the bracket is attached using the retainer bolts and flat washers leash Hiller. The stopper is inserted into the square tube and tightly pressed against its outer surface.

The bracket coupling bolt turn, and the leash placed along the longitudinal axis of the tillers

The unit is ready to work. Working in first gear, by reducing translational speed to increase the traction of the tillers. If in the process of hilling wheels are slipping, they need to be paired.