The final stage of the installation country of the fence is the installation of a gate and entrance. There are two main door types – hinged, consisting of two valves, and sliding (sliding, sliding), which manually or with automation move along the fence. The second type is considered optimal, as it saves space and does not create additional noise when opening. Consider how you can make sliding doors with their hands to make sure that their design is quite simple, but the installation does not take much time.

The contents

How to construct a classic sliding gate?

To the gate was moving smoothly and effortlessly, you need to consider the installation of a Foundation and every step of installation basic design. We should not neglect the Foundation: it rests on the moving element and is attached to the roller mechanism. Guide beam, which move the rollers, fixed on two stable supports. To prevent any failure of the fabric, use welding. Stand-trolley rollers are inserted into the beam and upper part are fixed on the bottom of the gate. In the result, the gate is easily shifted along the rail to one side. Now on the market you can find devices of automatic opening with a remote control, so if you want the whole mechanism can be upgraded and to make remotely controlled.

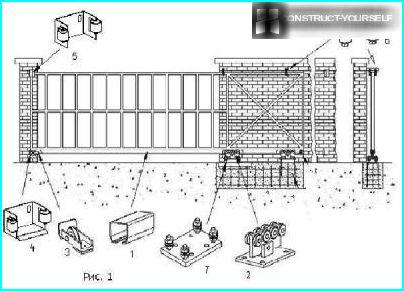

Diagram of sliding gate: 1 – guide; 2 – roller; 3 – removable clip; 4-5 — two separator; 6 – upper fixing bracket; 7 – adjustment platform

Step-by-step description of the installation design

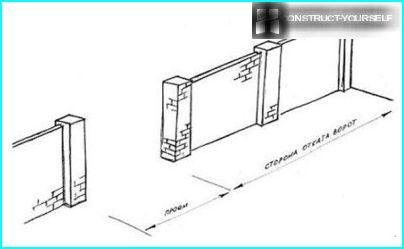

Before starting work on foundations need to prepare the opening for the gate is the place where you want to place a homemade sliding gate. Than already opening, the less you will need material for the device of moving webs. Of great importance is the weight of the structure, so as to install a heavy metal gate will require a more robust mounting than, say, to paintings made of carved wood.

Sliding doors can be rolled back as to the left and to the right. The choice of hand depends on the availability of space along the design

Usually, the time gate arrangement of the fencing is already installed, and then finished the edge elements of metal pipe, a brick or wooden pillars. The reliability of the gates and pillars will serve as mortgage details, the location of which can be seen on the attached diagram. The mortgage is called a flat metal segments secured along the support columns and reinforced with reinforcing rods. Additional elements of the valves are fixed in the soil and give the construction the necessary stability.

A concrete Foundation pouring

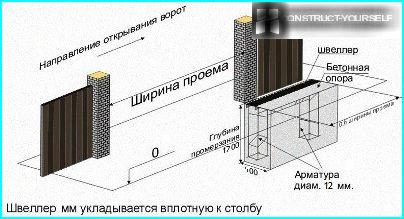

The first stage device of the pit for the Foundation. Its dimensions depend on the width of the opening and depth of soil freezing. In the middle zone of Russia the ground is frozen about half a meter, so the depth of the pit will be 170-180 cm, width 50 cm and length 2 m, provided that the aperture is 4 m.

In the pit, you need to install the embedded parts. To produce the required channel length of 2 m and a width of 15-16 cm, and valve rods of any diameter. The length of the rods is equal to one and a half metres – is such a depth they will sink into the pit. Rebar should be secured to the channel by welding. Fixing the longitudinal rods, fastening them together with crossbars to make a solid grille.

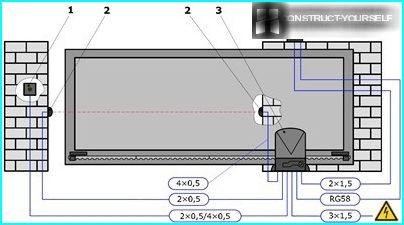

To install the automatic equipment necessary to prepare the site for tube and the center metal pad to tooling hole, in which is the cable of the actuator

Finished metal structure placed in a pit so that the channel was located along the line of movement of the gate. One end closely adjacent to the supporting pole. Horizontally positioning the beam will help building level.

Design mortgage is set from the outside, which will pull the curtain. During installation you should pay attention to the accuracy of the location of all elements

Simultaneously with the laying of the metal element are laying electric cable for the device automatic system. To protect electricians to fit pipes with a diameter of 25-30 mm. Instead of the metal products you can use the counterparts of plastic or corrugations. Special attention should be paid to the tightness of pipes and joints.

Automatic door opener: 1 – button switch; 2 built – in solar cells; 3 – electric drive; 4 – signal light with antenna

The final stage – filling the pit with the established mortgage. To fill the use solution prepared from a concrete mix M200 or M250. The surface mortgage – channel – should remain fully open. On the maturation of concrete is given 1-2 weeks.

Processing of the door leaf

Before installing the sliding gate will have to be assembled from components, the number of which depends on three indicators:

- the size of the web;

- the width of the opening;

- the total weight of the structure.

The weight of the gate drops on the slide and therefore should be taken seriously by her choice. Experts recommend to use products of the company Roltek from St. Petersburg. We consider several variants of equipment:

- Micro design of corrugated steel sheeting weighing up to 350 kg;

- Eco – friendly wooden and wrought iron gates weighing up to 500 kg opening not more than 5 m;

- Euro for the cloth weighing 800 kg, opening width up to 7 m;

- Max – for structures weighing up to 2000 kg and an opening width up to 12 m.

Frame moving parts consists of a shaped tube 40×60 mm with a wall thickness of 2 mm, for crates take a thinner pipe, with a diameter of 20 mm. the thinner profile of the pipe, the less the weight of the structure. For clarity – a few drawings of sliding gates.

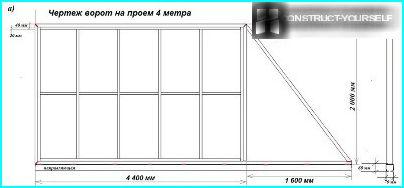

The frame for the gate may look different, depending on the size of the opening, height and components used. In the diagram, the sample frame for the 4-meter aperture

After welding the frame must be protected from humidity: for this purpose it is first primed tool on the metal, then apply paint for external finishing works

The installation of the paintings

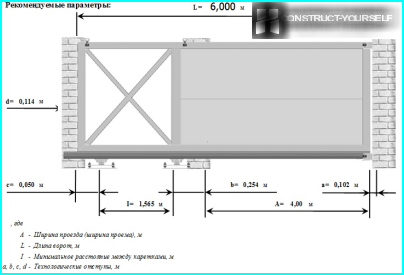

Work on the installation of sliding doors should only be started after the final cured concrete. To comply with horizontal movement of the fabric pull cord at a height of 15-20 cm from the surface mortgage. Then proceed to install the roller mechanism. Props must be set as widely as possible, preferably on the entire width of the fabric. Distance from extreme support to the post – 25 cm (small stock left for the end of the video). A little harder to calculate the distance to the second roller support. Usually use special formulas, but you can do without them. An exemplary diagram with the dimensions shown in the following figure.

When mounting the roller mechanism and sites should be required to provide all the technological margins, without which proper movement of the door leaf is impossible

For insurance from incorrect installation use the stand to adjust. They must be installed in the channel and fasten by welding. You then throw the curtain and make final adjustment of the horizontal position of the structure. To do this, remove the gate and roller bearings, and areas for adjustment, welded to the mortgage. Then on the pads fasten the roller bearings are returned to their canvas and fully close the gate. Using a level and adjustment check the horizontal design.

Adjusting all the parts of the mechanism established limit video. To do this, it must be inserted into the carrier profile and fix with the fastening bolts. For sure you can use welding to secure the roller cover on the profile. Roller plays a role of an end stop, so one bolt will not be enough. Also mounted and the cover profile to protect his groove against the ingress of snow and debris.

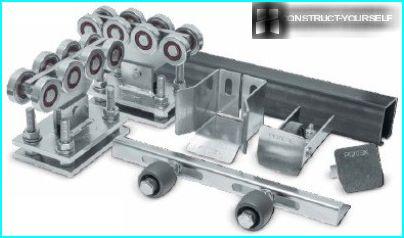

Set of rollers for sliding gate designs can be purchased in the supermarket building. It includes elements of the roller mechanism, the cover, bracket

One of the important parts that are installed following the roller — top bracket. It protects the locking mechanism against lateral movements. Bracket fixed on the top of the blade, turn the bolt holes into the side supports. Then fix it on a support pillar and check the adjustment.

The next stage is the covering of canvas or steel sheet lining. Any material starting to mount on the front of the gate. The individual sheets or boards attached to the sheathing and fixed with screws or riveting. Every other element of the profiled sheet overlaps the previous one on the same wavelength. The last leaf might not fit, then it should be cut off.

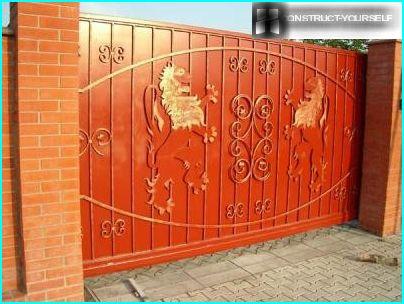

The owners, who value the prestige, do not skimp on the appearance of the gate. One of the most expensive ways of decorating is the artistic forging

Last set two trap – upper and lower. The bottom helps to ease the load on the roller bearings. It is mounted at the closed gate. Fix the upper opposite corners of the protective cloth, so that when the gate closed they are in contact with each other.

Cheap wooden gates of the lining can be improved with additional clearance, for example, to decorate the canvas with loops or piping from metal

Automatic leave for last. Together with actuator for sliding gates purchased the toothed rack, which serves for movement of the canvas. Usually it comes with the fasteners and elements sold by 1 meter.

Setting finally construction of the gate, check the working roller mechanism: timely repair of minor faults will protect against subsequent major repair.