Inherent in each of us the instinct is manifested in the desire to protect your home from danger. Fences, gates and wickets are an essential element of protection. But man is not alien also to the desire to surround yourself with beautiful things. It is not surprising that modern fencing elements besides their direct purpose also act as a decorative design of the site. The gate of corrugated Board mounted with their hands is one of the most acceptable options for creating reliable and aesthetically attractive designs that can decorate the front area of the site.

The contents

Decking as a construction material

Before you do the gate, offer to understand what the advantages of a profiled in front of others no less popular construction materials for the manufacture of walling.

The main advantages of corrugated sheets are:

- Excellent quality characteristics. Materials of manufacture are specialized leaves that are covered with several layers of protection: anti-corrosion, and after on the outer side of the polymer, and with inner lacquer.

- Simplicity and ease of installation. This material is ideal for decorating fences and gates. Design of light and at the same time durable metal plates can be erected in just two or three days, which, in turn, accelerates and reduces the cost of construction. Erected gates and fences from corrugated sheets look solid through and through.

- Aesthetic appeal. Wavy curved metal plates can have quite a variety of shades. The use of colored polymer coating by staining sheets of corrugated Board gives an opportunity to choose the product the desired color in order to make the gate, which is complementing the ensemble, will be in harmony with other building structures on the site.

- Long service life. The life of the structure, equipped with corrugated sheet can reach over 50 years.

Through a multi-stage processing of the material has a high corrosion resistance and ability to maintain their aesthetic appeal even under the influence of ultraviolet radiation and weather conditions

The main stages of manufacture and installation

Step #1 — selecting the best size

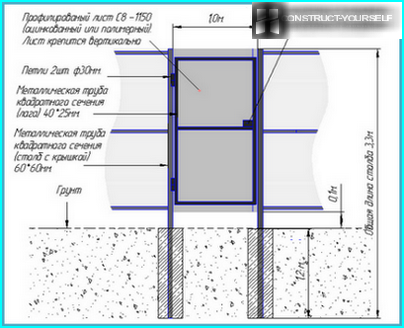

Planning to make in the fence of the gate, it is important to determine the dimensions of the structure. Optimal width of the gate – not more than 1 meter, height – not more than 2 metres.

The correct calculation will help to prevent problems associated with premature wear of the hinges and lock design, and the inconvenience arising in the process of operation when opening a broad sheet of canvas

Wanting to create a more dimensional design, should take into account the point that the increase in the weight of the sash can result in accelerated wear of locks and hinges canvas.

In the manufacture of a gate height greater than two metres the frame construction, it is desirable to Supplement the top and insert the crossbar. This will allow you to get ready a continuous sheet, which not only closes the space above the gate, but will reduce the load on the support post.

Step #2 — construction of support stands

To make a sturdy gate made of steel sheet, which regularly will serve for the next several decades, you need to build a stand for it. As support pillars can be metal pipes or pillars of stone or brick. During installation of racks it is important to monitor deviations from the vertical position, which can result in misalignment and malfunction of the finished product.

To prevent sagging of the support stand will help the construction of Foundation. The bookmark is 1-1,5 meters

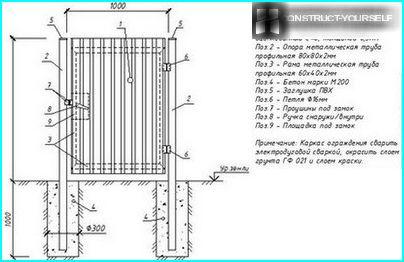

In a pit dug under the Foundation vertically to level of rack mounted and filled with a solution of fine gravel, sand and cement. Over the next 7-10 days concrete «comes» and freezes.

Step #3 — making the frame

The easiest frame is made of profiled steel pipe cross-section 60×30. In order to cut parts and weld the gate will need a welder and an angle grinder. Before cutting pipes on procurement, it is important to clean it from rust and scale by using mounted on the grinder wire brush. After that, the pipe surface must be degreased with solvent, primed the rust inhibitor.

During installation it is necessary to take into account the time that the distance between the door leaf and coated walkway or sidewalk shall not be less than 100mm

Please note! The working gap is essential for the normal functioning of the structure, even when the accumulation of ice in the winter.

Having defined the size of the gate, to start manufacturing its frame. To do this, the profile on the pipe it is necessary to mark the sheet dimensions and cut them with a grinder at an angle of 45 degrees. The establishment of such a chamfer will improve the quality of the weld, making it virtually invisible.

For the arrangement of the gate would require two longitudinal parts by 1.75-1.9 m and 2-3 transverse parts in 0,9-1 m. the Parts are welded to each other 2-3 cm tacks around the perimeter of intervals of 20-30 cm the Longitudinal and transverse pipes, including a Central cross tube must be located perpendicular relative to each other. Distance between all horizontal elements must also be the same. This will not only give additional rigidity, but also make her look more attractive.

To increase the structural strength, to pave the diagonal elements from the upper corner of the porch in the bottom corner to hang the rack

To increase the strength of the gate can also be inside the frame to carry a smaller frame of the same tubes size 20 x 40 mm. to Prevent distortion of the frame during the welding process from overheating by performing tack welding in a staggered manner. After welded the frame for the gate, proceed to the installation of additional elements – canopies, plates for fastening of the lock and outside handle.

Triangular «scarves» of steel plate welded to the connected between the parts, will improve the strength characteristics of the whole structure

Illustrative video manual for beginners, how to cook wicket:

Step #4 — installation of a gate

After completion of welding works it is necessary to perform cleaning of welding seams, priming the damaged area and painting the frame.

The corrugated sheet is easily attached to the frame with screws or rivets. The distance between fixings is dependent on the preferences of the owner: you can attach each wave of the sheet, and can and through one. Binding is the only binding sheet to the middle of the saddle frame.

To install gate can be used as traditional metal hinges and newfangled polymer veils. If the quality of the rack used metal poles, curtains are welded directly to them. To brick or stone uprights of the loop are attached by welding to the pipe profile, fixed by anchors or dowels on the pole. The gate can be hung on a support and check to see that castle.

To ensure that the gate is not opened on both sides, on the opposite pillar is welded to the limiter from the area. Sham strips will also cover the gaps between the posts of a gate and painting.