Rope ladder – a very useful household fixture. Folded it occupies a minimum of space, but if needed, when other main construction for any reason cannot be applied, it always comes to the rescue. Rope ladder is indispensable in the case of repairs hard to reach areas on the roof. Without it will not manage, if there is a need to go down in a narrow well. In the same house where a baby, this ladder performs the function of sports equipment, becoming the favorite toy of the baby. We propose to consider three of the most simple in execution of the production version of the rope ladder, put into practice which is able anyone.

The contents

Rope ladders consist of two basic elements, steps and ropes. Some craftsmen for decorating a homemade rope ladder fits shanks from shovels, which are in the horticultural or construction centers. Instead of wooden reek it is also convenient to use tubes of plastic or light alloy metal. Regardless of the material production stage should not have sharp corners that can interfere with the movement and hurt the man.

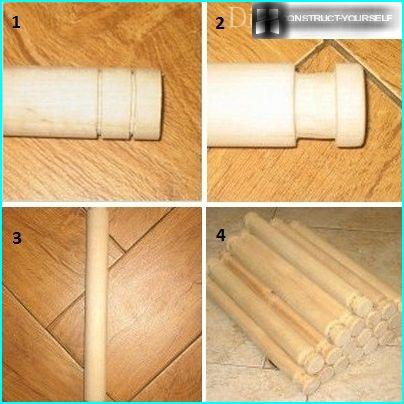

In most cases, the stairs made of wooden bars with a thickness of 4-7 mm round or square cross-section

Ropes for hanging ladders are made on the basis of natural and synthetic materials. Natural fibers of flax, hemp and cotton are durable. They are perfect for decorating «Swedish» wall and sports area. Synthetic materials such as nylon, polyester, nylon are considered more practical because they offer durability and high resistance to stretch. In addition, they are known for resistance to solvents, including turpentine, gasoline, and alcohol. Synthetic materials do not lose their qualities even if wet.

The optimum thickness of ropes for rope ladders from 7 to 9 mm. Rope of this thickness will not be cut hand in the process of operation and provide a sufficient reliability of the design.

The choice of materials of the rope ladder just depends on for what purpose the product will be used: to carry out work in the open air or in a closed, dry or humid place

In any case, hanging stairs make the length more than 15 meters, maintaining a distance between steps in the range of 25-35 cm As the rope ladder refers to the number of mobile structures, the weight of the structure should not exceed 20 kg. Suspended ladder shall be equipped with stops that will not allow construction to touch the wall. Length stops can vary in the range from 11 to 22 cm.

Option #1 — tying the rope around the stairs

For the manufacture of universal design, which will be useful in the economy, we need:

- Two piece of strong rope with a length of 20 m;

- 7 wooden slats with a length of 35 cm and a thickness of 3-6 cm.

- 1 roll of thick coarse strands;

- Power tools (drill, jigsaw);

- A fine-grained emery paper;

- Saw for woodwork and construction knife.

All the cuttings that will perform the function of steps of the ladder are connected together by two ropes. The surface of the sliced cuttings should be polished. This will avoid further trouble in the form of scratches and splinters in the palms. The length of the rope should be calculated taking into account that after tying knots in the finished stairs will be two times shorter than the original length of the rope.

To make a reliable and durable rope ladder that will safely withstand the weight of an adult, is quite simple

To rope in the braiding process not dismissed, their ends should sear. This can be done using a hot knife for cutting material. To prevent unraveling of the rope will help, and wrapping the ends of thick coarse thread.

Start to work. Before to bind the first rung on the end of each rope tie a loop diameter of 6 cm, which will continue to hang the ladder. Now take the first step and tie it on the rope. The cable fixing is performed, using the knitting technique of self-sealing of the node «constrictor», which provides very good fixation of the rails.

Clear guidance on the knitting site «constrictor»:

But even fixing stage using a trusted site «constrictor» there is always a chance that the steps may slide. To warn on both edges of each step, it is desirable to make the grooves. To prolong the service life of the rails, cuttings it is desirable to coat or treat with a special compound that protects the wood, but it will not make it slippery.

At a distance of one to two centimeters from the edge with a knife first, make slits with a width of 1.5 cm and a depth of 3 cm From them then form small grooves with rounded edges

Stepping back a distance of 25-30 cm from the first stage, the second tie bar. The same technology fixed and all the remaining steps until, until the ladder reaches the desired length.

Before to tie around each of the spars tight knots, you should make sure that the steps are parallel to each other. After all, to untie «constrictor», to re-bind the node, it is extremely difficult.

Positioning notches at the same distance parallel to each other allows a special device: it is enough to fix the rails between the slats and protruding outside edges to tie a rope around

Serially connecting all the stages, the ends of the ropes are also made in the shape of loops. The result is a ladder with a length of about 11 meters.

Option #2 — the crossbar through holes

The second method of manufacture of a suspended ladder is the necessity of making holes in the steps. Through them we will reach the ropes, collecting all of the slats in a single structure.

In the proposed variant, we will use wooden slats of square section with a length of 40 cm and a synthetic nylon rope. In each stalk, departing 3 cm from both edges, using a drill make a hole with a diameter of 1.5 cm Having a pair of holes, don’t forget to make sure that their diameter corresponds to the thickness of the rope. After that, the crossbar is carefully sanded, using sandpaper or sanding machine, and treated with an antiseptic solution.

Nylon rope, whose length is 10 meters, cut into 2 equal parts. The edges of the treated coarse thread or hot metal.

Proceed to the Assembly of the structure, the ends of both cords, make loops or tying knots. The free ends of the rope extend through the through holes of the first crossbar

The Assembly structure using all the same device, locking the crossbar between the wooden bars, nailed to a Board.

Long «tail» fold the rope in a loop, raise over the crossbar and wrap around the knot of the rope. The result is the first step, is fixed between the two nodes. The same technology collect and the other steps

Option #3 — rope ladder without rungs

In case, if there is no sense or time to build a rope ladder with the rungs, you can make the design, the role of steps in which performs knotted loops of rope.

Video master-class on weaving nubby stairs with no steps:

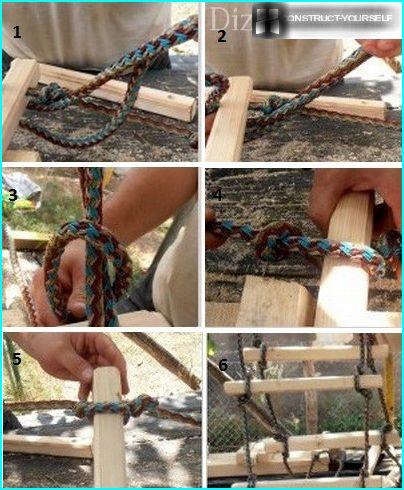

Interesting is also the option of stairs with «Burlatsky» loops. This technique of weaving is good because the result is not a node, and a convenient loop. In loops you can insert the legs and wrist to move your weight to rest when tired.

To do «Burlatsky» the loop is easy: them double the rope, forming something like a figure eight. Lower «tails» eight tie, and formed a circle to extend the upper part of the twisted loop. After using the loop easy to start using the rope for other purposes.

Step-by-step guide to making «Burlatsky loop»:

Knowing some simple secrets netting rope ladders, you will be able at any moment to build a comfortable design, sometimes so indispensable in the economy.