Gazebos – one of the most popular elements of landscape design that allows you to transform the look of any area. The variety of products made from wood, metal, polycarbonate and other materials, allows the owners of country houses to choose a gazebo which will help to create the atmosphere of coziness and comfort. Gazebos made of polycarbonate with their hands – the best option for a strong, durable and visually weightless design, which will decorate the yard for many years.

The contents

The advantages of polycarbonate over other materials

Note that you will not regret if will use in the construction of the polycarbonate. This material, widely used in construction, has several properties that are advantageous to shade it compared to other transparent construction materials.

Due to the special structure of the plate material polycarbonate when strikes are broken and do not give chips or cracks

The main advantages of polycarbonate include:

- High impact resistance (8 times stronger than acrylic and 200 times stronger than glass).

- The extreme lightness (6 times lighter than acrylic and 16 times lighter than glass). For the installation of lightweight panels made of polycarbonate are not required substantial supporting structures.

- The ability to withstand temperature changes from -40 to +120 degrees and snow and wind loads. This feature makes polycarbonate an ideal roofing material for gazebos, greenhouses and other light-bandwidth structures.

- High heat-, sound insulation performance and light transmission with a transparency up to 86%. The outer side panel is covered with a special layer that protects from ultraviolet radiation.

And yet, this material is easy to processing – bending, drilling, cutting.

In addition, the cost of polycarbonate panels are much lower in comparison with the same metal, and a wide range of colors allows you to choose the best option, the use of which will perfectly fit the design into the design of the site

The stages of erection of a structure

The installation of gazebos made of polycarbonate with their hands, like any building structure, is performed according to a predetermined algorithm.

Step #1 — selecting and preparing the space for the gazebo

Gazebos placed near the house, and also in the area. Well, if this place will be located in the shade of the trees and away from drafts.

The choice of place under the gazebo depends primarily on the functions to be performed by design. Capital planning to create a gazebo in a large area, you should prepare the ground for the erection of the structure. For this purpose, a suitable flat area, the ground water level which is low enough. Positioning the pad in the valley, should protect the structure from flooding, and to build for her a solid Foundation. Gazebos can be installed directly on the ground, on a specially erected platform — the basis. Deciding to create a gazebo for relaxing and gathering at the table, the cheerful companies, as base will be sufficient to install only the support tubes.

If the area is a pond, it is very wise to place a gazebo not far from it because in the heat of midday to provide additional fresh air

The most common forms of pavilions: square and rectangular, triangular, round and oval. The design of a traditional square gazebo can be decorated as a shed or gable roof so tent type roof

Step #2 — preparing Foundation base

If small and lightweight gazebos can we not lay a special Foundation for the construction of capital structures require a Foundation. This should make the layout of the territory and determine areas for future columns for the frame. The fill platform under the gazebo can be performed in parallel with the installation of the columns. For installation of columns it is necessary to dig pits of size sufficient to house the two bricks. This should still be a place for sleep 10 cm soil layer.

The columns are installed inside the holes, backfilled with drop-out and filled with cement. The cement hardens within a few days

The columns are installed inside the holes, backfilled with drop-out and filled with cement. The cement hardens within a few days. To prevent the ingress of moisture on solidifying the cement in the hole, you can cover the base of the columns wrap.

Step #3 — the process of assembling the frame

The material can be wooden poles, and metal profiles. Wood – cheap and easy to use material for extending the lifetime requires constant maintenance. Metal – durable and resistant to temperature material, the lifetime of which are much longer in comparison with the tree.

The principle of the Assembly of the frame like working with the designer and is simple to perform

Elements of a wooden structure held together with nails, screws, and metal screws and nuts. When working with metal, it is desirable to combine the connections using a welded connection details.

Step #4 — the glazed pavilions polycarbonate

The polycarbonate may be not only material for the reconstruction of the roof, and for patches of wall coverings. Windows made of polycarbonate for the gazebo will bring additional sunlight into a cozy area to relax and will give the construction lightness. Notched openings in the side surfaces, cut with a hacksaw, will create a visual effect of weightlessness and delicacy.

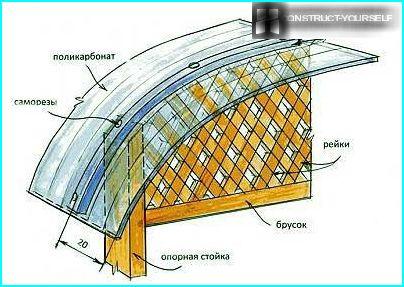

If you do the roof out of polycarbonate, it can be fastened with regular screws. There are also special thermowashers

So, first, the prepared polycarbonate sheets are transferred outlines all light-carrying parts of the gazebo. Then, using an electric jigsaw, handsaw or sharp knife parts are cut along the contour. Sufficient ease of cutting sheet – one of the valuable properties of the polycarbonate. To connect with metal design in polycarbonate parts should drill the holes.

Rubber washers with screws and silicone sealant to avoid unwanted leaks in the construction and destruction of the base of the leaves. For isolation the angled joints and joining of multiple parts, it is desirable to use special elements, which can be purchased together with the polycarbonate sheets.

Design and care for a gazebo

Comfortable and beautifully designed gazebo is a favorite area in the garden where you can enjoy the singing of birds and nature. In addition, for communicating with the guests now will not need to go into the house and instead spend the time socializing in the fresh air.

Vines planted along the walls of the gazebo and entangling design, will give the area a special attractiveness and comfort

Gazebo polycarbonate can serve as a functional element of landscape design for a period of not less than ten years. Special care design does not require.

The Windows and the roof of the gazebo made of transparent resistant to changes in temperature of the material, it is enough only periodically to wash with water from a hose or wipe off dirt with a damp cloth. The dirt is easily removed with soap and water. To clean it is undesirable to use detergents, which include chlorine, alkali, salt and harmful abrasive substances, under the action of which can damage the outer layer with UV protection.

The leaves are brightly colored tones used instead of the traditional transparent make it possible to design original of the species