Many citizens in the summer I try to travel to the country to relax, breathe in the fresh air, and at the same time and work on earth. In addition to the garden house in the suburban area, it is desirable to have a garage that houses not only the car but also various garden tools, hardware, power tools. Many gardeners use this space as a workshop, with some walls, machines and other devices. As they say, would be a garage and the use of it is a prudent owner will always find. To build a garage at the cottage with his own hands can be of different materials: timber, bricks, concrete blocks, cinder blocks, etc. for self-performance of construction works is possible to reduce the cost of buildings, decent saving on paying the services of a team of builders. A person with little experience in construction, and in a position free time, you can cope with this task. The process is significantly faster if to call for help from some friends.

The contents

The choice of building materials for construction of garage

Garages can be wooden, metal or stone. Metal garages are going very quickly from ready-made kit, however you will need the help of an experienced welder. Such constructions require additional insulation if you plan their operation in winter. The most widely garages, built of stone materials:

- bricks;

- silicate blocks (aerated concrete block);

- foam concrete blocks (blocks);

- breeze blocks (cinder blocks).

Stone buildings are the most reliable, because they are called capital.

Stylish wooden garage built on the dacha with his own hands, can perfectly fit into the overall design of a country site

Metal garage purchased flat Packed, some days going to the dacha with the active participation of an experienced welder

The main stages of construction of the garage

Any building requires training, during which a draft of the facility, purchased all the necessary materials, excavation carried out and the list goes on. Consider each stage separately.

The first stage: development of the project in a simplified form

Before you build a garage for the garden, we imagine the future structure and draw a small scheme of the project on a piece of paper. Of course, you can order technical documentation from professional designers, but then the savings will have to forget, because the services of these specialists are not cheap. The garage is not a piece of architecture, so you can design the object yourself. This will determine the answers to several questions:

- For what purpose built garage? Only for Parking lots? If you plan to carry out repairs and maintenance, then whether the observation pit? Do you need a cellar? Record all suggestions on a piece of paper and mention them in developing the plan project.

- What sizes can have a garage, based on the available free area on the dacha? Is determined by the width of the structure, length and, of course, height. If you need a garage just for Parking the car, then enough 3 m in width and 5.5 m in length. The height depends on the growth of the vehicle owner, because he is most likely to be in this room.

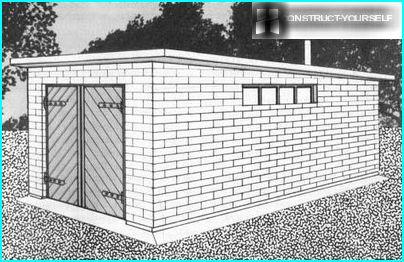

Sketch of capital garage, constructed of brick, block and other stone materials, with a pent roof, small window openings, ventilation system

The second stage: the breakdown on a country site

At this stage, proceed to the transfer of the diagrams sketched on a piece of paper, on real terrain. In the professional language of builders it sounds like «the binding to the terrain». Define the location of one of the corners of the future garage and drive with a sledgehammer or heavy hammer the first peg.

Next, using measuring tools (tape, angle) measure the other angles and also drive in stakes. Between the pegs pull thin nylon cord, which can go up to 40 meters, depending on the size of the garage.

As the stakes you can use the 40-inch pieces of rebar with a diameter of 10-12 mm. Usually takes up to 10 peg.

Third stage: excavation work

Begin active construction of the garage at the cottage with earthworks, in which dug a trench under the fill strip Foundation. The trench width is 40 cm, the depth depends on frost penetration in the area. Insufficiently buried the Foundation can cause cracks in the walls of the garage and other damage. In some regions enough and 60 cm, and in the other will have to dig twice as deep.

To the bottom of the trench dug for the Foundation, was not friable, the soil you choose to layer with a natural density (i.e. the ground in this place should not be bulk). The walls of the trench gently treated with a spade, ensuring flatness and verticality.

Fourth step: fill the strip Foundation

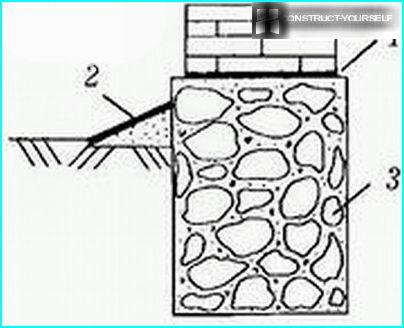

Of all the types of foundations you should choose rubble concrete option, since the fill can reduce the cost of cement due to the use of rubble stone. Work on the device rubble concrete Foundation are quite simple. Dug the trench laid rows of rubble stone, shedding each masonry cement mortar. The operation is repeated until, until it fills the excavated trench to the brim.

During the construction of the garage at the cottage is filled rubble concrete Foundation. In the diagram: 1. Waterproofing. 2. The pavement, preventing water penetration to the Foundation. 3. Rubble stone filled cement-sandy solution

It is important to note that the strength of the Foundation depends on the quality of cement. To the building of the garage is not shrinking and not covered with cobwebs of cracks, we need to buy cement (Portland cement) is not lower than 400 brand.

For mixing the solution take cement and sand in the ratio 1: 2,5. In other words, one part of cement should account for two and a half parts sand. Water is gradually added, ensuring the mobility solution. Water usually take as much as cement.

Step five: the unit cap, gate installation, construction of walls

Around the perimeter of the trenches set the level of the formwork, using the Board to fill the basement concrete. If the construction site were not cleared initially, then the basis of the reference height of the plinth is taken to the highest point. Added 10 cm on the base and displayed the horizon. On the dried surface of the cap is placed two layers of waterproofing, which uses a roll of roofing material. Horizontal waterproofing protects the wall from penetration of capillary moisture coming from the earth.

Before the erection of walls, you need to install the metal garage doors that will be fixed in masonry. The strength of the connection of the gate frame to the wall provide embedded parts, welded thereto in the amount of four pieces on each side. As embedded parts are used round rods whose diameter should be at least 10-12 mm. When the clutch metal rods close up to the seams.

By the way, don’t forget before installation, paint the surface of the gate, preferably in two layers. When installing, check the level of verticality of their position, if necessary, to place them under the corners of the flat stones or iron plates. The exposed gate prop, wooden prop.

After installing the frame of the gate, begin to lay out the garage wall method of chain construction. The stitches of the previous row overlap subsequent a number of cinder blocks or other stone materials selected for the construction of the garage. In accordance with the technology of masonry always start with the corners. Exposed between the adjacent angles of the pull cord, which put the remaining blocks in the row. Then again, raise the corners, pull the cord again and lay out another row of blocks.

To use a level when laying walls of the garage with your hands allows you to ensure the flatness of all surfaces, both vertical and horizontal direction

By means of a plumb periodically check the verticality of the walls. Close attention to the verticality of the corners. The horizontal position of stacked rows check the building level.

The ceiling of the garage serves as both its roof, so that the end walls have different heights, thereby providing the required slope of the roof needed to drain rain water. The upper part of the side walls is also performed with the slope, the elevation is for each meter at five cm, Height of front wall in which is inserted garage doors, usually is 2.5 meters, and the back (dull) – 2 meters. If you want to make the walls higher, the stonework is in need of reinforcement, which is provided by a metal grid placed on every fifth row.

Cement-sand mortar used for the masonry walls of the garage, mixed in the following ratio:

- bucket of Portland cement grade 400;

- four and a half buckets of sand.

Water is added until, until the solution acquires the consistency of thick cream. The plasticity of the cement-sand mixture give the usual clay or lime paste. The finished wall will be overwritten with cement mortar or plaster, and then whitewashed with lime.

For the implementation of masonry blocks at a height use scaffolding, which must withstand the working, several blocks and a container of solution

Sixth stage: the ceiling and roof

The ceiling is made of steel I-beams, the height of which may be 100 – 120 mm. Such beams are easily overwhelmed the garage, the width of which does not exceed 6 meters. To the width of the garage adds 20 cm and thus get the length of the beam. In the long wall of the beam lead 10 cm, while the cinder blocks in place of the supports is replaced by blocks made of reinforced concrete. The step of laying the beams is 80 cm.

Then the overlap «sutured» 40-millimeter planks on the bottom flange of the beams. From above them stretches the roofing material, which is poured slag, expanded clay or stack of mineral wool boards. Next is 35 mm screed of cement mortar, the surface of which must be carefully aligned.

After complete drying screed her coat with primer and cover with a waterproof roofing material (e.g., microtom, runemaster, etc.), bonded with mastic or by means of melting.

Seventh step: flooring and paving

The floor in the garage should be concrete to withstand the weight of the machine. On the leveled earthen Foundation poured a layer of small gravel or sand, tamp well and pour a 10-cm concrete screed. The concrete is prepared from cement, sand and fine gravel (1:2:3). With the help of placed beacons monitoring the floor surface, preventing bumps and hollows.

Outside the garage on the perimeter of arrange blind area whose width is two feet. Also, the earthen Foundation is covered with gravel, over which is poured concrete with a thickness of 5 cm Deck, building a slight slope that promotes rapid drainage of rainwater from the walls of automotive garage.

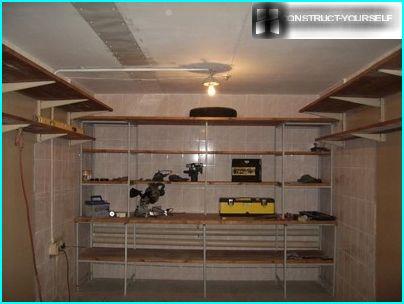

Interior finish of the garage depends on the preferences of the car owner and the availability of additional purposes of use of the premises. It is provided the lighting and the heating

So you can, slowly, build a garage at the cottage with his own hands. Performing works according to plan, and moving from stage to stage, you’ll be able to get a solid, reliable space for car Parking lot.