When the land has already been purchased, and the cottage still needs to build his future owners just need a utility room. Shed with your own hands is purchased or erected as a temporary shelter or even as a budget option in a country house. Subsequently, it can be used for storage of garden equipment, barbecue and furniture from the gazebo. Here you can put clothes and shoes for working in the garden or even a Bicycle, toys and other items that are used while outdoors. Depending on what communication will be used in the shed, it can serve as a bathroom, shower, bath, or utility unit.

The contents

Various designs are ready at the hut

For suburban areas often offer the following options for construction of huts.

Panel technology built

This type of structures are the most inexpensive. But even the small cost of this building called into question the fragility of the product from shields. Usually the base of such structures (frame) is made of lumber, siding — from siding. The role of the inner cladding plays a MDF or chipboard. In used as insulation glass wool or foam. For the sub-floor applied timber Board, and for finishing inexpensive plate material. For the one or gable roof structures often choose the iron roof of the small thickness. Such a structure is often deformed due to the lack of stiffening ribs, rolled insulation can settle, leading to the freezing of construction. To use this shed in the warm season one year.

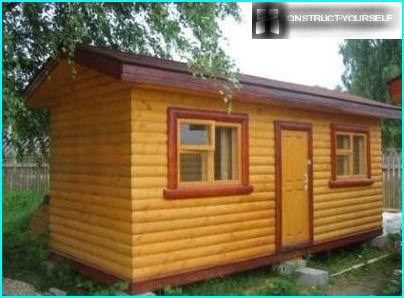

Billboard shed has a fairly presentable appearance, it is a pity that she will keep it for a bit: due to the lack of stiffeners it can deform

Frame construction

These structures shield cheaper in quality, but significantly more expensive. The cheapest option is the shed with a minimum number of Windows and no walls. Timber, which is used as frame structures, has a size of approximately 10х10см, whereby deformation are not afraid of him. Internal cladding is used siding. Plywood and fiberboard, thanks also to its hygroscopicity, is not the best option. The presence of a vapor barrier (such as asphalt) and mineral wool as insulation makes the house dry inside. Imitation of timber as cladding gives the building visual appeal. Floor and ceiling make the double. The downside is that the inner space of a frame cabins will be smaller than the shield.

Frame shed is much stronger shield, because during its construction used a more durable timber that is used vapor barrier and mineral wool do construction dry

Lumber and log cabins

Among other proposals on the market, these cabins feature a relatively high price. If shed just stay at the cottage and will be the bath, the products of logs or timber – it’s a good option. Only one should immediately take bath with all necessary partitions, and components (water heater, furnace, etc) to buy later. To build log cabins it is recommended that section of the rod not less than 100х150мм (log diameter, respectively, recommended in the same range). The building should be smooth plastered. As a cladding material for doors and partitions often use battens, but if you do log design that you can do.

Cabins of timber or logs is much more expensive than others, but it is warmer, safer and stronger, but to build such a structure only makes sense when it is precisely known that it will be used in the future

The shed container

Solely for the purpose of interim operation is applied to the container shed with a framework of metal channels, whose walls are made of sandwich panels. This reliable, durable and warm design it is very difficult to integrate into the landscape of the area.

Another option for the acquisition of the cabins is to buy already former in the use of the structure. Before she solved thoroughly inspect the building: the degree of wear is important. Find out about current prices for new cabins of the same type, the prices for rental of crane for transportation facilities. After all, transport costs should also be added to the cost of the house. Evaluate the possibility of access to the location facilities, find out if there are restrictions on entry of construction machinery in the village. And think not it be easier to make a shed with your own hands.

Office container-a container has many advantages. Such a structure, it is advisable to buy to live in it during the construction of the main house, and then sell. In the overall design of the garden, where everything is usually made of wood, this structure does not fit

The manufacture of cabins

In spite of sufficient simplicity built design, drawing cabins still needed. He will gently «enter» the shed in the existing space of the property, advise the Builder on the ground. Precaution will be unnecessary. This is especially important if the shed will operate in the future as a bath or guest house. The drawing will give the opportunity to visualize how to build a shed with your own hands will help you to make the correct calculation of the need for material and tools.

Selection of optimum

The location of the cabins at the site is determined depending on how the owner wants to dispose of it later. You must immediately decide whether the shed to remain on site or will have to sell as soon as the need for it has passed. If neither the tool-shed, no bath, no guest house to the owners of the land is not needed, the shed can be sent to another object, or simply sold. Then arrange the construction so that, from the roadway it would have been easier to catch a crane.

Otherwise, it will be necessary to disassemble the building, which is always undesirable. If the shed will be operated as a business unit, it is recommended to place it in the middle of the long side of the plot. Converted under the bath, the shed must be located at the far end of the plot, because in respect of such buildings need to comply with fire safety.

The Foundation design

The construction of the cabins performed their hands, starts with the Foundation of the device. The shed is not considered a heavy structure, so it is usually for its construction using pier Foundation. If the shed will be demolished in the future, to dismantle this Foundation will not be difficult. For temporary installations it is better to choose the cinder blocks — they are cheaper and they are easy to make and very.

So, the first step from the ground surface at the locations of cinder blocks you need to remove the topsoil, the earth well compacted and covered with geotextile and then backfilled with sand and compacted again. Prepared on the basis set cinder blocks, placing them in the corners and every 1.5 meters. Cinder blocks need to seal with roofing felt or bitumen mastic, after which the anchor method fixed wooden frame buildings.

Foundations for temporary structures is simpler than for capital: it can be easily disassembled, if the shed has to be dismantled

Planning to do a permanent shed, the master must give the Foundation more attention. In this case, the mold is removed from the entire surface, was covered geotextile and sand in 5 cm, which is rams. Under the pillars of the Foundation necessary to dig a pit 50 cm deep at the corners and every 1.5 m of the perimeter. However, the pillars can be put in and more. Pit is sure we’ll be paving geotextile and fall asleep in them 40 cm well tamped sand.

The Foundation is better to make bricks, and the height it should be 30 cm (10 cm to the ground and 20 above). In the Central part of the Foundation will be to drive the rebar at least a meter tall. It is needed for fixing the lag. Therefore, we leave an empty area in the center, which, after placing the rods, pour concrete. Do not forget about the waterproofing of the posts with bitumen mastic or roofing material. Control the level of a single height column.

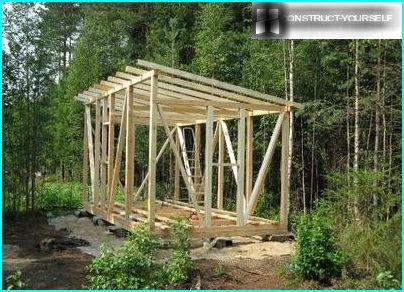

Create a framework of spaces and roof

When the Foundation of the company is not, proceed to the erection of the building. Formed the basis of construction: logs placed around the perimeter and carefully fix. After that, put cross and, finally, the longitudinal joists. On a frame cabins timber consumed 150х100 mm, of which mounted the floor support legs at the corners. Reliable connection provides vypily the lags at which the bars are inserted into one another and fixed with screws. The joists are strung across the armature circuits. For fixing the vertical and attached lag used corners and screws.

The frame structure is necessary to build as thoroughly as possible, because it depends on the quality of structures in General and its durability

The frame of the premises is ready, now you can make the roof frame. For shed roof bars need 50х100мм. In vypily bearing bars are inserted rafters. Fixation occurs when screws. The perimeter of the cabins, the rafters should reach 30cm. As coverage of select Ondulin, as not requiring special construction skills. The overall design of the roof must contain hydro – and vapor barrier and insulation.

On the rafters are laid the sheathing boards or wooden bars as Onduline – lightweight material. Onduline sheets mounted lapped upwards by means of special fasteners, which are included in the kit. You can now install doors and Windows.

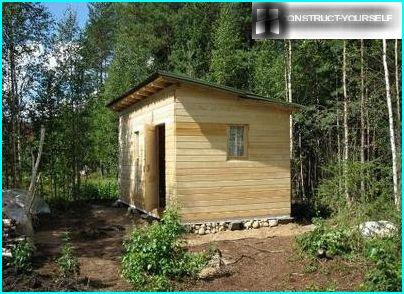

Execution of finishing works

Well, the basis of cabins has already been created and the terrible question, how to make a shed was not so terrible. However, the work is not yet complete. Vystelim the rough floor, not forgetting to treat boards with preservative. Between the two waterproofing layers placed a layer of mineral wool. It is important not to confuse what side waterproofing should lie up. Now the plank floor finish.

This is such a wonderful shed can be built with your own hands just over a week, if a strong desire and a good try

For inner lining of construction use OSB, if the structure is temporary or battens, if you stay on the site she has for a long time. For fixing that, and other material, it is preferable to use screws, not nails. Don’t forget about the vapor barrier and insulation. Outside the shed is sheathed, for example, the block-house. Left to make a comfortable porch and erection of holiday cabins can be considered completed.