If you want to vary the design of the suburban area of the original garden path or walkway, as proposed in supermarket products you are not satisfied for any reason, take a risk and create the tiles yourself, literally from scrap materials. For this you need to purchase a special plastic molds and learn how to prepare the solution for garden paths. Add a little imagination, building skills, patience — and your carpet will be not only durable, but also strikingly beautiful.

The contents

How to make inexpensive and beautiful?

Now it is easy to find everything to do with individual creativity. In stores you can buy handy plastic shapes-stencils for the manufacture of tiles. You prepare the grout, pour it into the form and after a few days get a tile of a given color, imitating the factory equivalent for the sidewalk.

Plain, colored, colorful tracks look great in the garden among the blooming trees and flower beds, and green, neatly trimmed lawn, and among the garden beds

The tracks are made of sturdy concrete tiles can last for decades – as to its strength, they are the Foundation of a building or the ceiling of a small bridge. They are comfortable and functional – all thanks to properly prepared cement mortar.

One piece solid form costs about 1200 rubles, and lightweight version of the stencil with holes of different shapes – much cheaper. Depending on the material, its price ranges from 50 to 250 rubles

Many master craftsmen of the purchase option prefer own creation, so do the forms yourself using wood or metal profile.

Of planed short bruskov it is possible to make a rectangle, a square lattice or a small hexagon, which will serve as a form for pouring cement mortar

How to make cement mortar?

The ability to prepare the grout at home will be useful to everyone who plans to do construction or repair work. Sticky mass that hardens over time, and the necessary bricks, and stone to create decorative compositions, and even to patch up a hole in the wall.

For the construction of garden paths needed a common solution that can be cooked with his own hands. However, its functional properties are largely dependent on the preparation of the material and proportions, so let’s discuss how to make the fill forms for garden paths, to serve for many years.

What you need to prepare?

Perhaps someone in a country owned and has cell mixer (in this case, the process of preparation masses will take place more efficiently and quickly), but it is unlikely in the average nursery, you can find this unit useful, so collect the Arsenal that is always at hand.

It is very important to correctly choose the capacity that would be suitable in size, and ease of working with it. Ideally, the volume of the tank must comply with portions of the solution that you want to cook at one time. Too little capacitance will cause you to repeat the procedure – but it increases the time spent at work, 2 times. In a large pot inconvenient to mix the components and create a homogeneous mass. Also important are the quality of the tank, as the resistance and strength of walls.

For small amounts of cement (if you do the tile slowly, e.g., on weekends) will fit a small container of durable plastic with a low side

If you have at the cottage was an old cast-iron tub, which is commonly used for stormwater storage, it can be a great temporary solution for dilution of cement or other large dishes that meet these requirements.

In addition to the capacity necessary tool to stir the mass until smooth. To wield a shovel or a piece of wood incorrectly – the solution will gather in lumps, which will affect the poor quality of the tiles.

The best equipment is a construction mixer, or, as it is called, hand mixer; in its absence, you can use a drill with a special nozzle

Try to lay down in one place, so that the cooking process did not have to go out and delay the process.

Feature selection

For standard, widely used cement mortar required 3 components: cement, sand and water. Everything seemed to be just mixed everything together and got great material to fill in forms. However, there are several important points, the violation of which will immediately affect the quality of the tiles. For example, sand. You can find several types of sand that are different, and particle sizes, and weight, and composition.

We will approach the usual quarry or river sand having features like purity (for this it is necessary to flush), uniformity, absence of defects

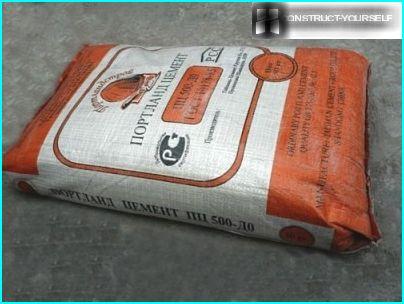

Cement – the dry mix in paper bags – must be loose, fresh, not expired. If your back is kept a few bags from the construction site 10 years ago, better say goodbye to them, because a good solution from such cement not to.

Here are some tips from industry professionals that will help to make a great solution:

- If you notice dry mixture in little lumps, powder sifting, using a special sieve (to work with stone rather cells 10mm x 10 mm for plastering you will need a sieve with a mesh of 5mm x 5mm).

- The best type of cement for road works – grade 300 or 400.

- Correctly determine the proportions of all three components. For tracks perfect traditional ratio of 1:3, where 1 part of cement is 3 parts sand. Bulk materials can be measured in buckets or other appropriate containers.

- To give a specific color or changing some characteristics (viscosity, strength) are added to the solution of modern components, such as plasticizers or colored granules.

In preparing the solution make sure that it was not fatty, containing much binder. Fat mass is plastic, easy to apply, but forms a composition that quickly dries out and eventually falls through the cracks – for garden paths is not necessary. With a lack of binding element, we get the skinny cement, which would be too long to harden and also have unsuitable characteristics.

We need good cement, after curing, having excellent strength and wear resistance, and this is just and necessary to observe the proportions.

Cement bag weighing 25 kg is from 180 to 250 roubles. The price depends on the manufacturer, brand and quality of dry mix

Water is added «the eye», first a little, then poured in small portions. The result is a mass, resembling the viscosity of thick cream.

Preparation of cement mortar

Keep in mind that the finished solution can be used within a few hours, then it will be unsuitable for fill, so pre-prepare the table, shapes, stencils – all that is needed for the production of road tiles.

Into a container in thin layers fill the cement and sand should be at least 5-6 layers. It is necessary for high-quality, uniform mixing of the components. Stop when the total height «pie» to reach 25-30 cm and then take a shovel and try to gently but thoroughly mix the components of the mixture: the more you move with a shovel, the better will the next solution.

The homogeneity of the dry cement mortar can be determined by eye. If you have any doubts in the purity of the masses – again pass through a sieve

The water can be added only after you make sure ready dry mix, or rather, in its homogeneity. It is better to take a small container and add in small portions so as not to overdo it and make the solution too runny. Pour the water slowly, stir gently mass.

A mistake novice builders are experimenting with pouring temperature of the liquid. Some believe that hot water will accelerate the process of breeding, and a specially heated, the other poured the icy liquid. You’re not it can adversely affect the quality of the solution. Water should be the same temperature as that of the surrounding atmosphere in our case, we are talking, of course, about the warm season.

Ready-to-use mixture to fill the forms should be slightly more liquid than cement mortar for brick masonry

Another caveat concerns the moisture content of sand. Often use the sand stored on site. It is obvious that during rain it could get wet. If you use wet, heavier sand, liquid pour even less. The solution is already ready? Start to fill. Depending on the density and the viscosity of the composition you have 1-3 hours to pour the solution forms.

Mosaic tiles, cement-based: a detailed photo-instructions

Not everyone likes a dull, gray tracks, reminiscent of the city the streets are paved or concrete road, so we offer to your attention the process of making tiles, conventionally called mosaic. Our tile is far from the masterpieces of Spanish or Italian professional masters, nonetheless, a nice even squares with a pattern of colored stones on a background of garden plants look great.

Tile size depends on your project garden paths. Large, with a side of 50 cm, can be put into one row – you will get a narrow lane, small (30-40 cm) in two or three parallel series, or even haphazardly

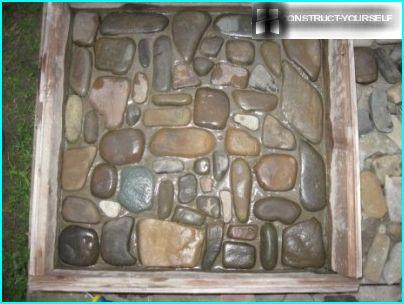

Unlike regular tiles that consist of one cement, our variant requires an additional «significant» component stones. They can be large or small, plain or colored, round or flat. The stones can be replaced with pieces of ceramic or glazed tiles, pebbles, as long as they don’t slip in the rain.

Colored stones for tiles took on the Bank of the nearby river. If you are not lucky with the water or simply river Bank was sandy, don’t worry – stones required fraction is always possible to purchase in one of the construction companies

The basis for the tiles is cement mortar prepared according to the standard scheme described above. Take the classic formula: 1 part cement, 3 parts river sand. Cook the mixture in a large bowl, using a small plastic measuring containers.

Dilute the solution in portions, separately for each tile, is also possible, but this process will be very long and time consuming, so prepare the solution in a quantity which is enough to fill 6-8 pre-prepared improvised forms.

Forms are straightforward and represent boxes with low walls formed by plates with a length of 30-50 cm Thickness prepared tiles can be from 5 cm to 15 cm

Carefully fill in the solution form, covered with plastic wrap, greased (suitable used engine). Below the tiles were the same thickness, put an equal amount of cement mixture. For accuracy it is possible the edges of the plates to hold the line denoting the height of the tiles.

The cement mortar surface level carefully – prepare for the laying of the stones. It is important to maintain the necessary consistency of the mass, as in too slurry stones will fall

Do not wait until the solution solidifies, spread on the surface of the stones. Before preparation of solution it is possible to hold a rehearsal, lay the stones in a box «dry», to find the approximate number of stones required for 1 tile.

To start with the corners – so the tile will be stronger, and the stone picture more clear and correct. If you use stones of different sizes, try larger to lay on the perimeter

Continue alternately to lay the stones, creating natural, or geometrically correct picture. You can alternate the elements of a different size or a different color.

Laying out the perimeter so that the long side of boulders lay along the edge. This will prevent the breaking of ground at the edges after long use and extend the life of the garden path

First lay out the larger stones, then fill the free space small. The result is a beautiful colored tiles, appearance is not inferior to the factory counterpart.

On the sample stones are laid out in natural order. There are other options – staggered, spiral, rows, diagonal, herringbone, etc.

Outwardly projecting elements is a shortened life tiles and Woe to those who on it will go, so all the stones are carefully pressed inside, to the top plane equal to a concrete Foundation.

For leveling the surface and ramming the stones are also use tool in hand. In this case, we used trowel left after plastering

So, all active work on the creation of tiles is finished, you have to wait. Below the concrete is not covered with cracks, it is necessary to wet 1-2 times per day. After 3-4 days it is ripe, the frozen material will depart from the walls of the casing, and the tiles can be removed, freeing the form to the following portions of the solution.

The finished tiles can be placed immediately into place. This is usually prepared by base – lined and fenced borders sand and gravel «layer cake»

Tile suitable for the construction of tracks or venues of any size and shape.

A concrete solution will be useful not only for filling in forms, but also for the creation of individual tiles solid cover – you have to fill cement mixture the seams between the tiles or use it as a glue

The track, which spent a minimum of budget funds, that looks amazing, especially if the area is another design created from stone and cement mortar.

The magnificent wrought-iron gates and high stone wall – the perfect backdrop for garden paths made of river stones. And note – everywhere it is the normal cement mortar prepared on your own

And finally — a great video on how to properly prepare the grout and pour it into molds for tiles: