Beautiful fence is the business card of the house. He must not only protect their owners from «uninvited» guests, and can also be a wonderful addition to the design of the site. Because of the diversity of types of fencing effectively allocated wrought iron fences, sleek lines and open weave metal which just fascinates with its beauty. However, created by the masters of fences are quite expensive, and therefore can afford to have such beauty on the site can not many. To make wrought iron fences with their hands – a difficult but feasible task to accomplish which can be knowing and considering the main points of the product Assembly.

The contents

Varieties of designs of wrought iron fences

Beautiful wrought iron fences are made of metal bars that are placed at a small distance from each other, forming a graceful protective design. No other types of fencing do not have such a diversity of patterns and do not deliver such aesthetic pleasure as the delicate wrought-iron fences. There are three basic types of fences: protective, decorative and combined.

Protective fences are a solid sectional fencing that provide strength, elegance and beauty

All elements are extruded sections are connected by welding. Assembly and installation of the sections is quite simple and fast. Protective fences belong to the category of cheap metal fencing.

Decorative fences are different from their counterparts a higher artistic level of performance. Luxury fences are obtained thanks to the special method of finishing iron artistic forging

Decorative fences are of high value because often they are made to order and design chosen by the client or the master.

A combination of wrought iron fencing, which is a cross between the above options represent welded wire fences augmented with elements of forging

Combination of fences combine aesthetic quality decorative fencing and protective structures.

The stages of construction fences with elements of forging

A combined version of the fence is the optimal solution for making your hands of the fence decorated with elements of forging, because the cost of its construction go much lower decorative counterparts. For the manufacture of such a fence will need a machine welding electrodes, angle grinder, equipment for cold forging (snail, torsion) and other small tool to work with metal.

Preparatory work

One of the first stages of construction is the construction of the base. First we need to mark the territory of the columns and calculate the required number of sections. Measurements should be done with extreme precision to finished sections freely located between the pillars.

It would be nice at this stage to make a drawing or a sketch of the wrought iron fence on paper showing all necessary dimensions.

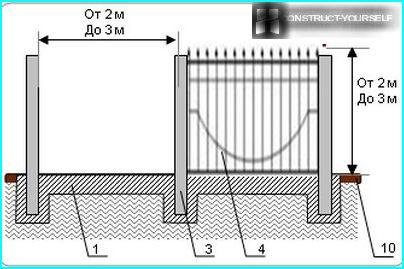

Wrought iron fence on a concrete base, where 1 – strip Foundation, 3 – supporting metal pole, 4 – forged elements, 10 – ground level

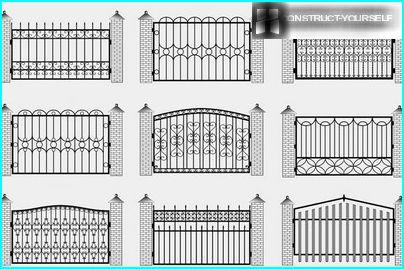

The original design of the fence can come up with on their own, to choose to entrust the master with a well-developed aesthetic taste. Here is a small selection of options.

Thinking through the sketches of wrought iron fences is important to consider how possible technological execution of the plan option

With wrought iron sections complement the brick and concrete pillars, and conventional metal support structure.

Under the supporting pillars of the fence, you can lay traditional tape or pier Foundation, or to raise them on pile-screw Foundation. It is also possible pillar in a pre-dug trench with the subsequent welding of reinforcement cage and concreting. This design will be strong and durable support for the wrought iron fence.

The poles should be placed vertically, otherwise the error can lead to distortions of the structure. Mounted on metal support pillars are mounted with special fasteners. So that rain water does not leak into the cavity of the metal pillars, their tops need to make or purchase a decorative waterproof caps.

Article topic: Setting poles for the fence: ways of assembling different designs.

Manufacturer of wrought iron fence sections

Fences made from round metal rods or faceted cross-section 12×12 mm, the thickness of which allows to provide the sufficient strength of wrought iron fencing. And many of the artistic blacksmiths prefer to work with faceted rods.

If you compare the decorative qualities of the rods, the most impressive and representative look of fences made from rods with faceted contour

Collect each section begins with the manufacture of frames of metal profile. To get a smooth frame construction with right angles, its Assembly must be completed on a spacious and flat surface. All the corners of the frame should fit snugly to the work surface, and is not in limbo.

The assembled frame is made with neat welds can be mounted vertical lances, decorated with forged ends

Proceed to the most creative stage of making the fence. Among the wide range of ready wrought iron decorative items for a fence, you can always choose the most suitable combination that will be an effective addition to walling.

Deciding to make wrought iron balusters in the form of vines, the delicate spiral curls, or other self, better to start trying to do not too difficult to manufacture elements. On mastering the new technology will take some time but be accustomed to the tool and acquiring the skills, you can create more complicated Lacy patterns.

Example of creating patterns for the fence on a makeshift lathe:

Making curls better to run on the equipment, which is placed during the forging process in one place, so that all the elements of a pattern are the same diameter.

In order to visualize what the look will have a section in the assembled condition, curls, rings, torsion bars and other decorative elements should be put inside the frame. Having defined the ornament section, using chalk or marker to mark location of items.

You can start welding. It is advisable forged items only «grab», and not to weld «tightly», this will give the opportunity to make adjustments and to shift them in the right direction. «Potholders» it is desirable to perform in the least visible locations. Making sure that all the elements sit «in their places», you can flip a section and thoroughly boil all «potholders».

Article topic: Artistic forging in your hands — how you can apply in garden?

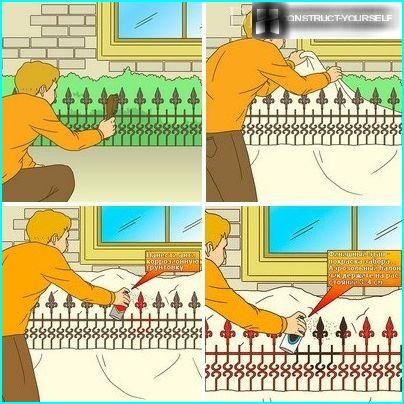

After welding a fence is not particularly attractive in appearance. That’s okay, after painting any shortcomings will disappear. When the fence has cooled, it is possible to prepare for painting.

The surface is rubbed with grinders, metal brushes and wheels for Stripping, clean rust, oil and debris, degrease and coat

For degreasing you can use any solvent. Dried surface of the fence can be treated with anti-corrosive composition and open paint. When working with metal is better to choose anti-corrosion compositions of contrasting colors relative to the color of the surface, then when applying clearly seen to be still raw sites.

If you order pick up at Smiths…

If after reading, you think that wrought iron fencing is too difficult in the manufacture of self and you have decided to order them from the experts, you will be helpful to view this video:

Wrought iron fence, decorated with bars that mimic vines or tree trunks, able to blend in any design area.