The contents

- Stages

- Instruction on how to do the calculation when assembling metal

- Do rafters

- Cornice boards, filing hooks

A good roof is the key to warmth and dryness in the house. From the quality of material you select and how well it goes, depends on the life of the structure and its reliability. One of the most popular materials on the market is metal.

Technical characteristics of the metal ↑

First, this material is very easy to install. Secondly, he can easily tolerate a variety of atmospheric effects. Thirdly, it is able to withstand mechanical deformations.

The standard sheet width is one meter and 18 inches. Length varies from one-half to eight metres. Interestingly, the useful width in this case only 1, 10. m. the sheet Thickness is in the range of 0.4 to 0.5 mm.

The average life of high-quality metal with proper installation fully according to the instructions is approximately 60 years. However, you should note that auxiliary materials, such as boards, sealant or insulation can come into disrepair faster. No wonder the roof from time to time require cosmetic repairs.

The roof of metal is not susceptible to combustion. Each sheet is light in weight, which greatly simplifies installation. It is also worth noting the versatility of the fastener system. It allows to realize almost any design imagination.

The color of the siding that you choose will depend on the facade of the house. For example, under the red brick is well suited brown tile. Thus for a comfortable installation of the roof slope can be as low as 14 degrees.

The unique properties of metal when damage to a certain area allow you to do without installation of the whole structure. Not surprisingly, most vacationers choose this material for their roofs.

Typically, the metal is made from galvanized steel. In some cases, use a copper sheet. But in this case, the cost of the product increases several times. For the sake of objectivity it should be noted that installation of both types is the same simple.

If we talk about the latest trends in this segment of the market, increasingly, for the manufacture of metal used aluzinc. This material is considered relatively new. Rather, it is a common metal sheet, which is covered with alloy of aluminium, silicon and zinc. As a result of the performance of the product increase. And the installation still is not much more complicated.

The weight of one square meter of metal is in the range from 3.5 to 5 pounds. This allows for quick installation and easily lift the sheets of the roof even at high altitude.

Installation ↑

Stages ↑

Before you begin such an important company as installation, you must know that you will have to do and in what sequence. At this point it is best to install metal tiles by performing these actions:

- To make precise measurements.

- Calculate the amount needed for the work material. Don’t forget to include in the estimate insulation, insulation and fixing materials.

- Make installation of roof system.

- Install the cornice Board. She will later be attached to the hooks of the chute.

- Hem the overhang of the roof.

- Mount the front Board, mounting hooks and gutter.

- Secure kontrobreshetki.

- Put waterproofing coating.

- Around additional elements secure the crates together with reinforcing straps.

- Install bracket, which subsequently will be mounted cornice.

- Take care of the apron around the chimney.

- Make installation of siding with their hands. If you wish, install Windows.

- Do the butt bar and the upper carpet and outside corners and straps skate.

About the construction work and should not be forgotten. It is impossible to ignore the fencing and walkways. They will ensure your safety, if in the future will have to get on the roof.

Special attention should be paid to the drainage system. From, how well you do, depends on the security of the house Foundation. Moreover, if you make the piping and to take care of the tanks every time it rains will provide water for irrigation.

At the end of the installation of metal roof surface is cleaned of dirt accumulated over time. Are treated problem areas. For example, if the work had scratched the protective coating, it can be easily restored.

In addition to external construction works, still need to do interior design. Usually it consists of laying the insulation. You also need to take care of the mounting counter-battens. To inside is not condensation it is necessary to make a vapor barrier.

Instruction on how to do the calculation when assembling metal ↑

As an example, take the standard galvanized sheets. There is only one protective coating layer, which is able to protect the entire structure from various atmospheric influences and mechanical damage.

Metal – a galvanized steel sheet with protective coating. Full width of the sheet is always more work surface 80-120 mm, so choosing a coverage, you need to know exactly the size of the site, which will be mounted design.

When calculating you need to take the length of the sheet and divide by its width. Rounding is done in a big way. Need to measure the slope of the roof. To do it bottom-up. The calculations must take into account the eaves, it is usually sufficient 0.05 m. the Overlap amounts to some 0.15 m in each row.

If you buy the leaves directly on the plant, it is possible to negotiate individual sizes of panels of metal. In this case, the installation will be much easier and faster. However, for the individual parameters will have to pay. In this approach, the installation can reduce the amount of waste. The fact that the leaves can have different sizes. This, in turn, allows more effective to put them in particularly difficult areas.

During installation you need to put the leaves so that the bevel was completely closed. Otherwise, the rain moisture will penetrate into the structure, gradually destroying it. Heavy rains will cause permanent leaks.

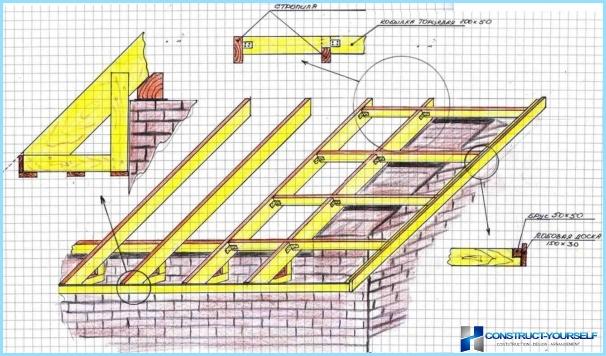

Do the rafters ↑

First, you need to do the calculation step. It is best for the installation of metal to use a beam with a cross section of 150 by 50 millimeters. Is the optimal size. The interval between each sheet of 70-80 centimeters. In the case of its increase will need to install the sheathing.

Special attention should be given to the wood that you will use when installing metal. Its humidity should not be above 22%. Also don’t forget the antiseptic and fireproofing. This will protect the roof from possible fire, fungus and insects.

Cornice boards, filing hooks ↑

When installing metal cornice Board are cut the slots. In this part of the roof will later be fastened to the hook of the chute. It will provide the entire design necessary rigidity, thereby ensuring safety.

In order to fix my roof and install the front Board, you will need:

- rafter,

- sheet metal,

- waterproofing,

- the strap under the ledge,

- a head-Board.

Combining all these elements, you will be able to carry out the installation of metal. Front Board is better to fix galvanized nails for greater reliability. It is attached to the ends of the rafters.

When installing metal, you should be aware that the space under the roof must be ventilated. To make this possible, you need to make vents. For filing it is best to use a siding or corrugated sheet.

Bar binder stuffed on the wall at the same level as the lower part of the face Board. Between them will need to fight the Board. The result of your work will be the crate.

The hooks need to put them all in the gutter. Installation of these locking elements is an important part of the installation of metal. They need to be fastened to the cornice Board.

First are the slots. Then the Assembly hooks. The distance between them is equal to the distance between rafters. The base for the fixing screws are.

Installation of sheathing under the metal roofing ↑

Installation of lathing involves installing straps gain. Also for quality support of metal you will need:

- rafter;

- waterproofing and vapor barrier film;

- contrace;

- primary, vertical and horizontal lathing;

- insulation.

The initial crate when installing metal mounted at the top of the sheet. Its cross section must exceed all other crates on the size of the wave height. Styling is strictly parallel to the eaves

Before mounting sheathing to support siding need to install mounts for all elements of the design. Otherwise you will have to break the whole structure.

Special attention when installing sheathing under the metal roofing should be given the ridge lath. On top of the rafters are nailed two extra straps. The distance between them shall be 50 millimeters from each other.

Installation snegozaderzhateley for metal ↑

Tubular snegozaderzhateli installed with special supports around the tiles. Initially these structures were made of wood. Now the main material is steel.

Install metal roofing on a remarkable parallel to the eaves. The distance between them must be 0.5—0.8 m. the attachment points put wooden bars.

The results ↑

As you can see, installation of metal with his hands — is quite a feasible task for everyone. Just follow the described steps and use quality materials. Most important thing is to carry out the calculations, then do not buy sheets or waterproof film.