The contents

The combination of efficient operation, based on the economical use of fuel, and ease of use are key requirements when selecting the boiler. The main goal of engineering design is to maximally use the heat from combustion of fuel in the reduction of volume of energy source. Pyrolysis boiler is fully consistent with the imposed conditions and represents a practical option for home heating.

The types and the device pyrolysis equipment ↑

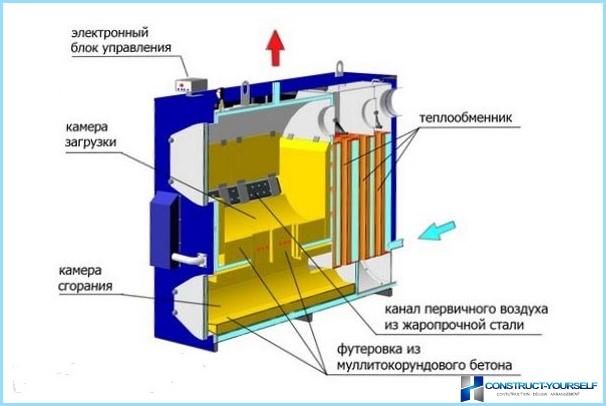

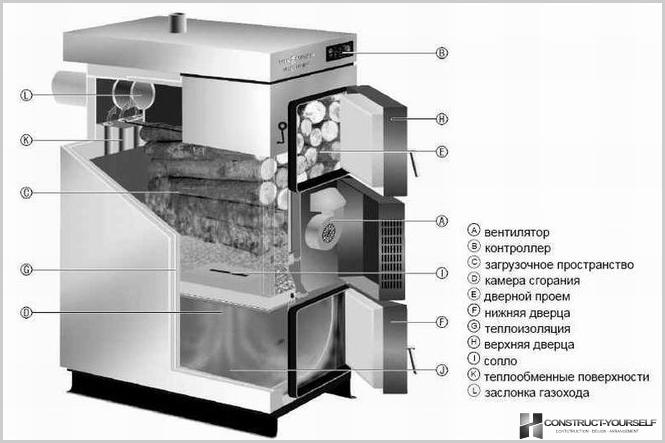

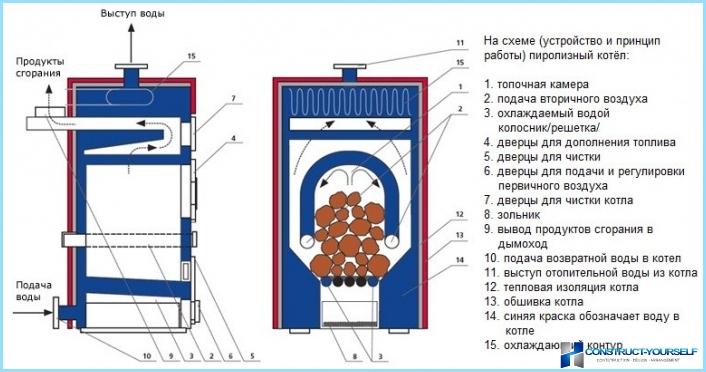

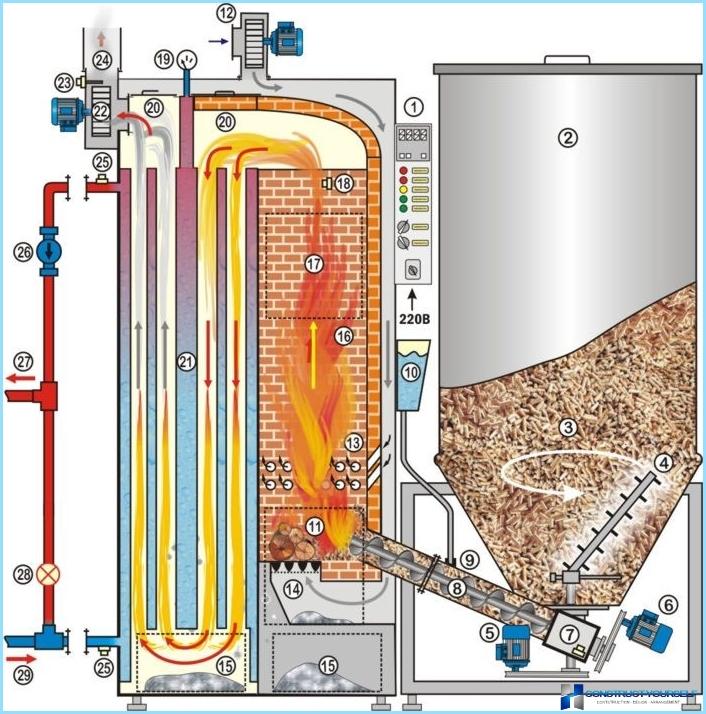

What kind of boilers can be attributed to the pyrolysis and whether there are structural differences between the models? What are the advantages and negative sides of the units long burning? For a start it is worth mentioning that pyrolysis boilers operate exclusively on solid fuel. «Heart» the boiler is a combustion chamber consisting of two compartments:

- The loading portion for solid fuel generating gas.

- Sector afterburning, the function of which is organization of process of burning of pyrolysis gases.

This sector is connected with the exhaust tract, by which heat energy moves to the coolant. Here are deposited the remains and combustion of solid fuel in the form of soot. Why the second name of the device pyrolysis – gasification boiler. All these units are equipped with pull switches. The absence of this element turns to gas boiler standard equipment direct combustion. It is the closure of the valves provides the beginning of the pyrolysis process in the combustion of solid fuel.

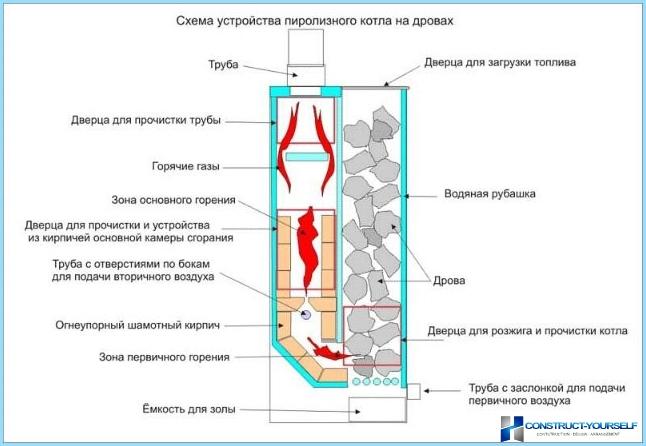

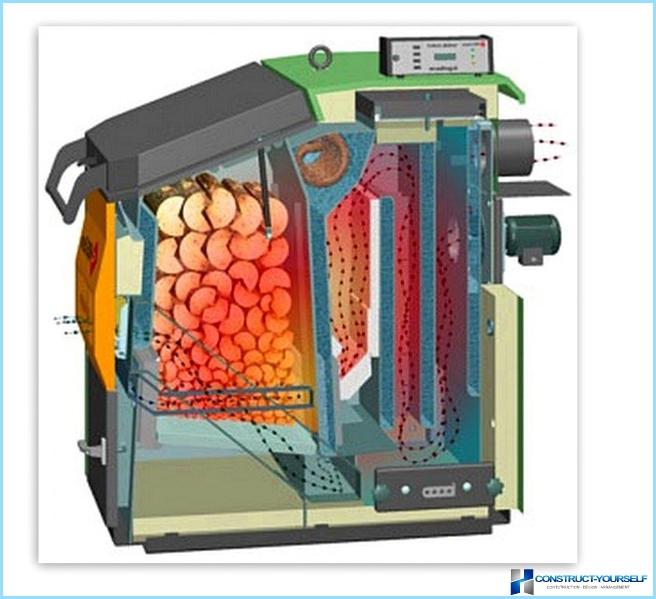

There are various models of pyrolysis boilers, the difference between them lies in the location of the camera afterburners. It can be fitted at top or bottom. Features popular design of the unit on a solid fuel with the lower chamber for afterburning the following:

- Among the advantages noted handy bookmark fuel, exhaust gases are in the flue pipe installed from the bottom.

- A significant disadvantage of such gasification boiler is the need for regular cleaning of the lower chamber due to falling ash from the primary compartment.

Design of pyrolysis solid-fuel boiler with the top of the camera afterburners are less widespread, but has significant advantages. In this pyrolysis gas is supplied to the afterburning compartment through the nozzle, and after complete combustion moves to the chimney. After cooling the products of combustion are ejected. The disadvantage of this model is the increased consumption of material on the arrangement of the flue tract.

Structural differences between solid-fuel boilers of a pyrolysis type there are in the arrangement of the thrust, which is forced and natural.

For forced ventilation, installed fans and exhaust fans, which happens automatically. Their work is characterized by a large effective combustion, but subject to the availability of electricity.

The principle of operation ↑

Whereby pyrolysis of solid fuel the unit has high efficiency, we consider in detail. Thanks to a full combustion chamber and the turbine, one tab of solid fuel enough for 10 to 12 hours. How it works:

- Gas boilers are equipped with a software device whose function is to establish comfortable heating mode.

- After receiving the specified parameters is carried out automatically control the operation of the turbine.

- The compartment for solid fuel load is served a certain amount of air, providing the required combustion mode. This allows you to maintain in the system the desired temperature.

A key principle of effective functioning of pyrolysis boilers is the use of technology for generating gas by decomposition of the wood. This is done when exposed to solid fuel to high temperatures in the range 200-800onWith provided limited air supply. That is, the receiving of the main flow of heat is not in the loading chamber where directly is the combustion of solid fuels. Secreted in low oxygen pyrolysis gas passes through the nozzle in the afterburning chamber and mixed there with secondary air, is combusted at a temperature of 1100-1200onC. It promotes the ignition of the smoke exhauster, which creates the required thrust. This process is characterized by the release of enormous amount of heat. Parts of the boiler, which accumulates a small amount of waste in the form of ash and soot and require regular cleaning.

The promotion of the pyrolysis gas through the heat exchanger is accompanied by a transfer of thermal energy to the heat carrier, after which it is removed through the chimney. This ensures maximum utilization of the generated heat and the extension of the process of combustion of solid fuel.

Features steel and cast iron models ↑

Body solid-fuel pyrolized boiler mainly made of steel of a thickness exceeding 5 mm. the Disadvantage of this material is the susceptibility to corrosion processes, which has a negative impact on the life of the equipment. To avoid such problems will allow the purchase of solid fuel boiler body is made of cast iron, with high quality and reliability. Compared to steel, features a cast-iron boilers pyrolysis is higher in the following positions:

- the period of operation;

- heat;

- resistance to corrosion processes;

- cast iron boilers are less susceptible to acids and resins.

The nuances of the choice of fuel ↑

Efficiency gasification boiler largely depends on the type of fuel used. In General, it is a suitable raw material of organic origin:

- wood;

- coal;

- pellets;

- peat;

- wood waste processing.

Download of the sawdust and chips is unacceptable due to contradiction to the very name of the boiler «solid fuel». The use of these materials will not provide the process of separating pyrolysis gas because of poor combustion. The best option is wood burning which is accompanied by the formation of large volumes of gas in excess of all other sources. As mentioned above, a high boiler efficiency of pyrolysis is possible provided that the use of dry fuel.

Cost analysis of sources of thermal energy has identified the leaders: among them are pellets and wood pellets. Both are the result of woodworking and have a low cost. However, the fine fraction material is recommended for use in combination with the wood.

The minimum size of the fuel gasifying boiler is 7-10 cm in transverse dimension. The use of chips or sawdust allowed in amounts not exceeding ¼ weight of the total solid fuel.

The advantages and disadvantages ↑

Improvement of boilers for solid fuel pyrolysis units provide a number of advantages, among which should be noted:

- Under the conditions of operation of boiler efficiency is 85-90%. This is achieved through the combustion of solid fuels without the rest.

- The need to download wood occurs twice a day. When operating the pyrolysis of boiler at reduced capacity process can be reduced to a one-time refill within 24 hours.

- Adjusting the temperature in the room provides a reduction in fuel consumption.

- The interaction of the pyrolysis gas with carbon is accompanied by the minimum formation of hazardous substances. Together with the practically complete combustion of solid fuel in the boiler, this ensures a low level of atmospheric pollution. Compared to traditional units, he reduced three times.

- Reducing the number of purges gasification boiler with full combustion of all components of wood.

Consumers pyrolized boilers inherent individual shortcomings:

- Dependence on supply of electricity.

- The majority of pyrolysis boilers single-circuit units, so perform a single function of heating the room. For the process of heating the water, care should be taken about the installation of additional equipment that accompanied the new material costs.

- The cost of the device for solid fuel pyrolysis type above the price of traditional solid fuel boiler. However, due to the economical flow of materials in the future, this cost overlaps with success.

- Despite the automatic adjustment of the heating process, the charge of solid fuel pyrolysis boiler is done manually. This procedure gives the consumer some inconvenience because of the systematic control of consumption of raw materials.

Choosing among the many models of pyrolysis boilers note that the units are operating exclusively on wood pellets difficult to maintain, so the need to attract service professionals. The cost of all pyrolysis boilers is directly dependent on the presence and quantity of technical improvements.