The contents

- The device and principle of operation of pyrolysis boiler

- Design features

- The types of pyrolysis boiler

- Advantages and disadvantages

- The operation of the boiler with pyrolytic combustion

- Modes of operation for gas boiler

- Scheme of pirakata

- Installation of pyrolysis boiler

- Fuel for gasification boiler

Pyrolysis or so-called gasification boiler – heating equipment powered by solid fuels. The solid-fuel pyrolized boiler is characterized by high efficiency and effectiveness, time of operation of the thermal unit on one tab fuel can reach from 10 hours to two days. Gasifiers can be used for heating as residential and industrial buildings.

The device and principle of operation of pyrolysis boiler ↑

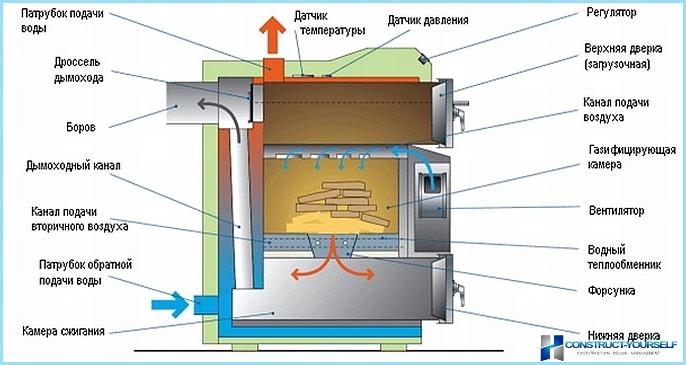

Gas heat unit has a rather complicated structure, the device pyrolysis boiler includes a variety of components and parts, the main feature of pirakata from traditional solid-fuel apparatus – furnace, consisting of two chambers.

Design features ↑

- camera download or the pyrolysis chamber;

- the combustion chamber;

- throttle valve (gate);

- grate;

- channels air supply (primary and secondary);

- water heat exchanger;

- fireplace.

As mentioned above, the furnace gas generator Assembly consists of two chambers arranged one above the other and separated by a grate. Pyrolysis furnace of the boiler, usually made of alloyed heat-resistant steel. The grate made of cast iron, steel or refractory ceramic. Using a primary flow channel of the oxygen transport of outside air into the pyrolysis chamber, the second channel provides air flow into the combustion chamber. Water heat exchanger of the boiler, pyrolysis or so-called «water jacket» for heating the liquid heat carrier of the heating system. In the construction of piracetam use tubular or plate heat exchangers. The chimney is the flue products of combustion into the atmosphere.

Design gas boiler provides the possibility to adjust the power of the heating unit in the range from 30 to 100%. As the regulating element acts as a valve, located at the rear of the thermal unit. Depending on the set temperature of the coolant at the outlet, the controller automatically opens or closes the valve.

The types of pyrolysis boilers ↑

Depending on the design of directly are divided into units with natural draft and with forced airflow. The main advantage of gasification boiler with natural draught is the independence of the unit from electricity. The disadvantages are higher demands on the exhaust channels. Directly with natural draught fitted with a chimney height of not less than 5 m. the Thrust of the chimney must provide a negative pressure in the furnace in the range of 16 to 20 PA, should be enough thrust to overcome the drag force of the air-gas path of the boiler and the flue.

Design pirakata with forced blowing involves the use of a fan. The flow of air into the gasification chamber and the combustion can be ensured in three ways:

- a blower mounted on the front wall of the boiler;

- fan (exhauster) is installed on a chimney;

- the equipment is mounted and the output, and at the entrance to the gas path.

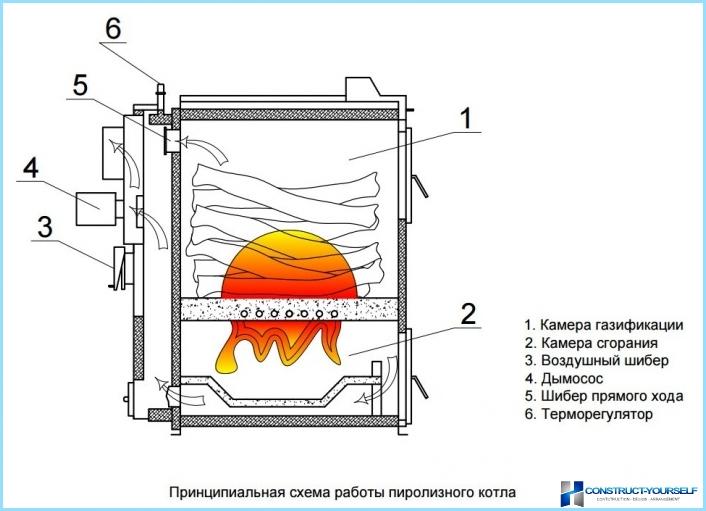

The design type of pyrolysis boiler depends on the location of the chambers of gasification and combustion. In units with a natural draught flue of the afterburning chamber is located above the gasification chamber, so the air flow occurs in the upward direction. In devices with artificial draught, on the contrary, the combustion chamber is located above the combustion chamber, the movement of air from top to bottom.

The advantages and disadvantages ↑

The advantages of pyrolysis thermal unit include:

- Up to 90% efficiency;

- fuel economy;

- environmentally friendly;

- ease of maintenance;

- minimum amount of ash, no soot.

Another significant advantage of gas boilers is that they are compatible with any heating system.

The cons are:

- high cost;

- complex design;

- cumbersome;

- increased demands on fuel relative humidity;

- the need of electricity connection (refer to the models boilers with forced draught).

The operation of the boiler with pyrolytic combustion ↑

The principle of operation of pyrolysis boiler based on the thermal decomposition of solid fuel to chemical constituents:

- carbon;

- pyrolysis gas.

The generation process of fuel pyrolysis gas from wood and other solid fuels in high temperatures, within the range of 200-800Zero, in conditions of oxygen deficiency and the subsequent afterburning of the released gas, which is mixed with preheated secondary air in the afterburner chamber. In the process of pyrolysis gases at the outlet of the boiler mainly contain carbon dioxide and water vapor, the amount of harmful impurities is minimized.

Modes of operation for gas boiler ↑

All pyrolysis boilers are designed to work in three modes:

- the mode of ignition. In this mode pirakata throttle valve is maximally opened, the flue gas is led directly into dimmendaal;

- operating mode – the damper is completely closed, the camera is in the process of pyrolysis. Air supply depending on the model of the boiler provided by natural or by forced;

- mode of loading – the process of decomposition of the solid fuel under the influence of temperature continues, the throttle plate is opened, it runs the reload fuel.

The uploading of the fuel should be conducted at a fast pace in order to avoid filling the air with carbon monoxide and heat loss.

Scheme of pirakata ↑

Scheme gasification boiler is a sequence of the following processes:

- loading of fuel in the furnace of the boiler ignition;

- once the fuel has ignited, the valve is covered, the combustion process gradually passes into the stage of decay;

- on the primary channel to the chamber load served outside air, part of which is used to maintain the decay process and achieve the required temperature gasification;

- pyrolysis gases through the grate is received in the combustion chamber;

- to ensure the process of combustion of pyrolysis gases in the afterburner chamber through the secondary air channel;

- the volatile products are burned, releasing a certain amount of heat, part of which goes under the grate and is used to maintain the pyrolysis, the second directly goes to the heating of the boiler;

- waste products of combustion pass through the water heat exchanger and displayed in the flue pipe;

- maintaining the optimum combustion temperature is maintained by temperature control.

For more information on the work of pyrolysis boiler can be gleaned from the video

Installation of pyrolysis boiler ↑

To ensure safe operation of heating equipment must be followed the basic rules:

- pyrolysis boiler installed in a separate room;

- distance from the substation to the wall at least 200 mm;

- the cross section of the ventilation duct in the boiler room should not be less than 100 cmTwo.

Fuel pyrolysis boiler ↑

In gas vehicles as fuel can be used the following materials: wood; brown and black coal; briquettes; peat; wood waste.

The quality and type of fuel depends directly on the efficiency of thermal installation, the battery life on one boot, the lifetime of the thermal unit. So, the time of combustion of wood pyrolysis boiler depending on the type and hardness of the material is about 6 hours. The burning time of lignite – 8 hours, the black about 10 hours.

Studies have shown that the most rational type of fuel for piracetam is dry wood, the moisture content of which does not exceed 20%. Despite the fact that the time of the burning of the wood is less than that of coal, but the amount of the generated pyrolysis gas many times more. Experts assert that the wood not only increases the efficiency gasification boiler, but also increases its durability.

The moisture content of wood is directly related to the amount of the generated heat, so a kilogram of wood with a moisture content of 20% has a heat output of 4 kW/h when this amount of firewood with a moisture content of 50% – 2 kW/hour. Camera download gas-solid fuel boiler involves the use of wood with a diameter from 10 to 250 mm and lengths from 40 to 65 cm.