Set for heating small housing gas or electric boiler is not always advisable, especially if you live there on a permanent basis. To heat a small area much more practical oven. Selecting for these purposes, a compact girl, you will get the desired result in a quick period of time. How to make Dutch oven without assistance, will be discussed further.

Design features ↑

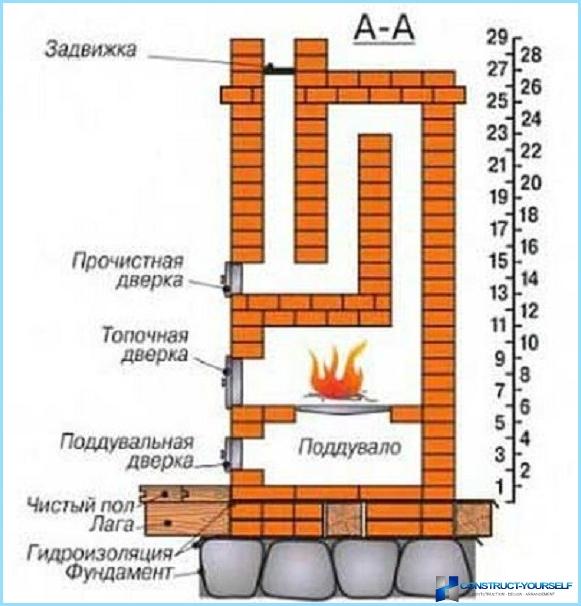

The principle of operation of the heating design is based on an artificial lengthening of the path of movement of flue gases, due to which they almost fully transmit thermal energy to the walls of the furnace. The lack of physical-thermodynamic tricks provides ease of erection of the Dutch if you have experience with masonry. Characteristic property of Dutch ovens is the ability to change the classic scheme porjadovki. If you want to make improvements, it can be supplemented with:

- a stove for cooking;

- fireplace;

- changed the height of the structure by lengthening the chimney.

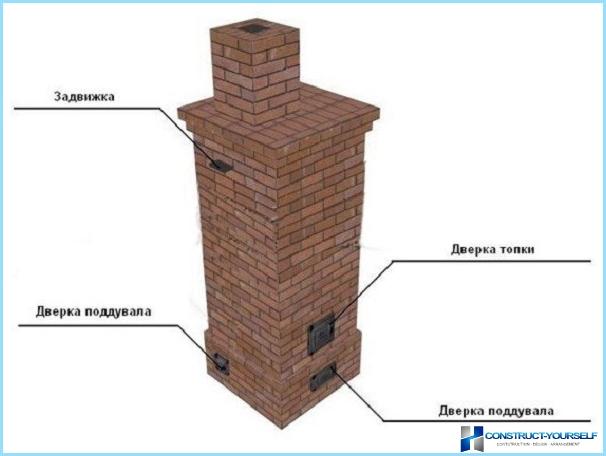

The structure of the stove comprises the following main elements:

- combustion chamber;

- ash pan;

- smoke moves;

- compartment for cleaning;

- valves are responsible for the adjustment rod;

- fireplace.

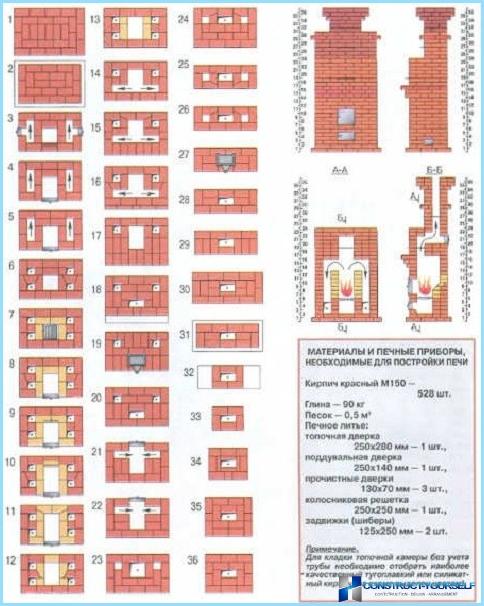

The invention designs the stove in Holland was due to the need to achieve rapid heating with a minimal fuel consumption. This is due to the variability of weather conditions. Achieve goals large proportion between the winding area of the inner surface of the cooler to the volume of pledged fuel. For clarity, the classical scheme of the furnace of the Dutch is presented below:

Initial designs were appearing deaf furnace, in the process of improving the oven added a grate and a door with podduvalom. The absence of a furnace of the arch allows you to make the Dutch independently even non-professional potters. The main advantages of the Dutch oven the following:

- It is possible to make design changes without loss of efficiency.

- The compact dimensions. The minimum size 52х52 cm allows you to heat an area of up to 20 mTwo.

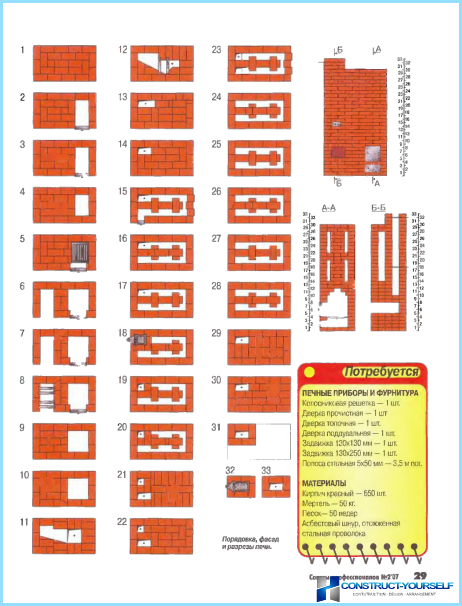

- Conserving supplies. For the arrangement of the 650 Dutch enough bricks.

- Lightweight design does not require a strong Foundation.

- To make the furnace can be of core or overburnt material. The only condition is that the furnace is laid with refractory bricks of high quality.

- Great design of the Dutch is able to heat a space up to 60 mTwo.

- The oven is optimally suited for installation in the country due to the rapid heating and slow cooling process.

You should consider the choice of fuel for the Dutch, it does not accept the fast failing of raw materials.

Material requirements ↑

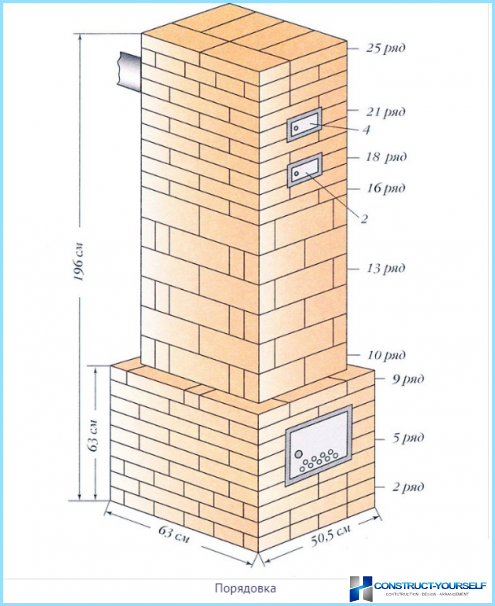

Before beginning the process, you must read the options, what the Dutch can be folded independently and to select the optimal design. From the variety of types, we propose to study two options porjadovki ovens Dutch:

Selecting any scheme of laying of the furnace Dutch and calculating required quantity of materials shall be transferred to the procurement and development of necessary tools. To make the heating the design, you will need:

- Refractory and common brick.

- Components for mortar: sand (prefer river), clay and water.

- Metal elements Dutch: doors, grate, damper.

- Asbestos cord and flexible steel wire.

- Metal strips with a width of 5 cm with a thickness of steel 5 mm.

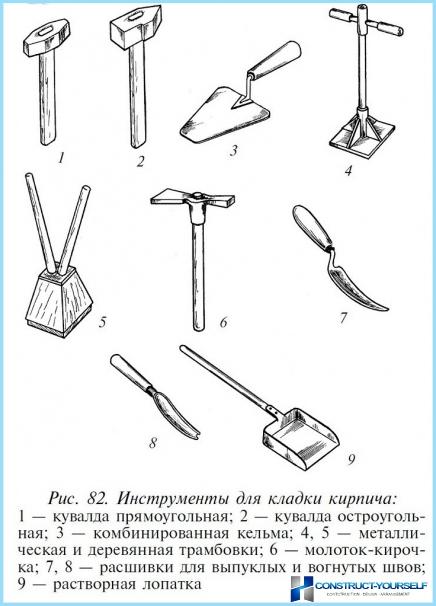

Tools that are useful in the process of erecting a furnace of the Dutch, represented in the figure below:

The formation of the Foundation ↑

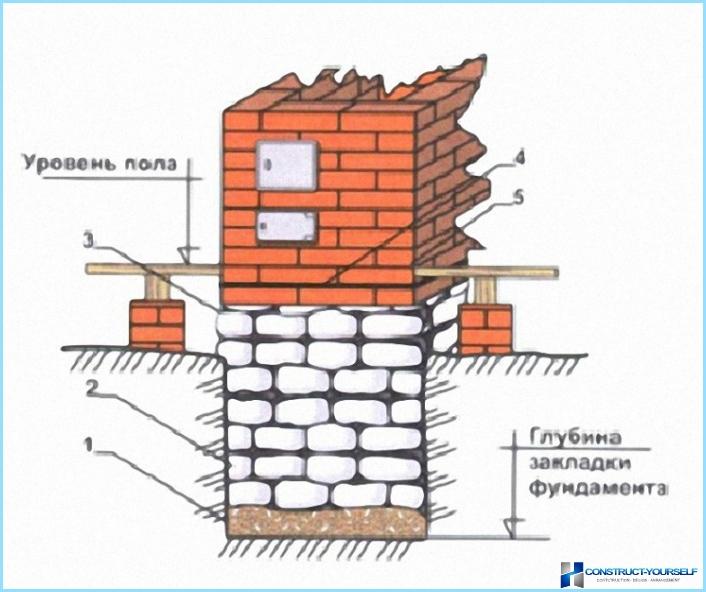

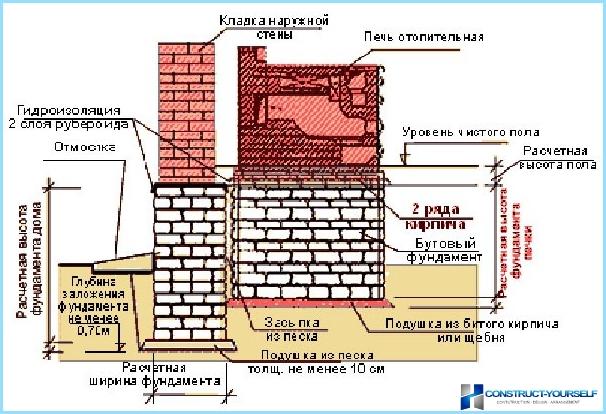

Although the furnace has a relatively low weight in relation to other similar structures of brick, to make a reliable base Foundation is still necessary. A sensible solution in this case will be a monolithic slab.

Dimensions strengthened the base be at least 120×120, see the Foundation of the furnace is not associated with the Foundation construction.

The construction is carried out with the use of concrete or brick. The first method is characterized by durability and cheapness, subject to the availability of free sand and gravel. However, there are also negative aspects of this decision for the installation of the furnace Dutch:

- the complexity of the process, even in the presence of mixers;

- the extreme difficulty of disassembly of the structure.

To arrange for a furnace of Dutch brick Foundation easier, although it will cost more concrete structure. The process of construction of the Foundation of the Dutch oven includes the following steps:

- Outlines the borders of the future Foundation.

- The pit must be done to a depth of 0.6 m.

- On the bottom of the pit formed a bed of crushed stone with thickness of 15 cm After filling of the material it is carefully leveled and tamped.

- Of reinforcing bar, formed mesh, the cell size which is 10-12 cm: at the cross points of the horizontal bars using wire fixed vertically reinforcing bars.

- Pouring the Foundation of the furnace Dutch precedes the construction of formwork. Its walls for the purpose of waterproofing hide roofing material or treated with resin.

- Poured concrete mix.

- To do «dry topping» the Foundation of the Dutch oven, the surface sprinkled with dry cement in a small volume.

Masonry ovens ↑

Before you start laying a furnace to make a solution and process based.

Preparation of the solution and treatment of the base ↑

For solution required to break up large fragments of clay and sieved sand. Crushed clay also is in need of sifting. In the absence of sieves for this purpose, suitable mesh from old bed tubular type. The clay required for several hours to fill with water, subsequently excess liquid is removed. After swelling of the clay it is mixed in equal volumes with sand, adding 1/8 of the water.

Solidified the Foundation of the furnace Dutch covered with a material with waterproofing properties. To make a good defense will help the use of roofing felt or sarking.

The lining ↑

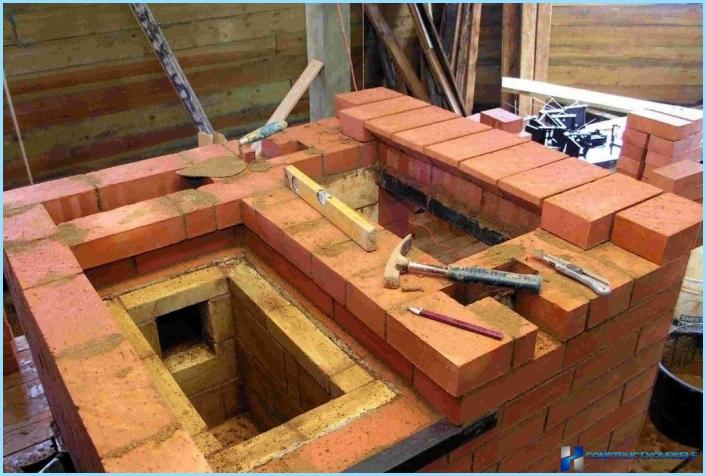

Implementation of the process of a laying of the furnace Dutch according to the lining consists of the following steps:

- The first row is made up of twelve bricks. Making sure using a level correct horizontal line, plane, is treated with a clay solution.

- Using asbestos string wrapped door blew, then be installed. As fastening material is steel wire, which is inserted into the box and curled.

- According to the lining is installed in the second row.

- Starting from the third row, masonry stove Dutch need to make fireproof bricks, as this section forms a combustion chamber.

- Grate whose dimensions are 20×30 cm, is fixed between the third and fourth next.

- Then the bricks are set on edge. Place the partitions in the chimney of the furnace Dutch on the rear wall with brick laid without mortar. This will allow for further exploitation of the structure to remove it in order to make cleaning the oven Dutch. The alternative is to install doors.

- The process of fixing the doors of the furnace are similar to the actions for installing in a furnace of the Dutch door blew.

- On the fifth row of bricks lay flat, similar to the previous level.

- The bricks of the sixth row again put on edge.

- In the seventh row of the far wall consists of material recorded edge, all other sides are formed flat. In the future, the bricks on edge not being.

- At the stage of laying the eighth row is completed the design of the furnace door. On the inner walls of the Dutch oven, lined with firebricks, you need to make the bevels. If you want, this will ensure continued operation of the furnace according to the principle of the fireplace.

- On the ninth row is offset ago. With the tenth series begins laying out the foundations of the chimney of the furnace Dutch.

- After the formation of the eleventh number is required to install the valve. On this element, as with doors, it is necessary to make the coil using asbestos cord.

- While working on the masonry of the twelfth number was required to make the joint between the chimney and a metal pipe. ?Warning! In places the removal of the chimney through the roof, it is recommended to make the protection of insulating material. For these purposes, perfect mineral wool.

- The height of the tube furnace Dutch is determined individually, but with the condition to over the highest point of the roof she stood not less than 0.5 m.

Conclusion ↑

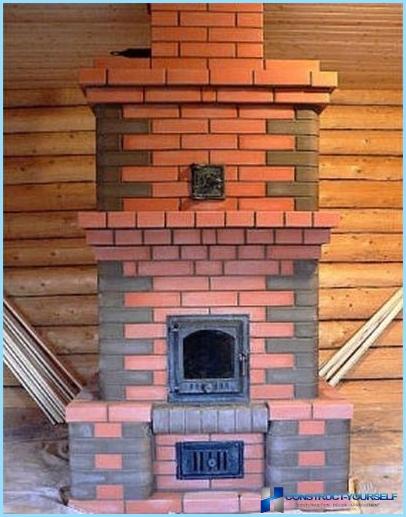

Execution of the finish depends on personal preference. Methods range from a simplified whitewash and the usual tiling to fine decoration of tiles. Provided masonry with the use of quality bricks, you can leave the Dutch oven without subsequent finishing. To prevent accidental fire from the dropped fuel before the combustion chamber it is necessary to make the protection of a steel sheet laid on the floor surface. The period of drying stove Dutch lasts a fortnight, while the furnace door is recommended to keep open. Before full operation, it is desirable to burn fuel in the chamber some paper to test the traction.

To see interesting moments of the formation of the Dutch oven on the following video: