The contents

- Design features of sectional doors

- Features of production technology and used materials

- Preparation for independent installation

- A quality installation is precise and correct measurements

- Prepare connector for installation of sectional doors for garage

- Start the process of installation lifting the sectional door

- Fittings used in the installation of sectional doors

One of the most important elements in modern exterior of buildings are automatic sectional garage doors. Thanks to its high resistance against burglary, they gained wide popularity and established in our days almost all garages, industrial buildings, service centers and many other buildings. Design features of the gate to attract attention to their appearance, they also have high technical characteristics and is very easy to operate. In addition to the protective functions of the gates are also perfectly sealed space.

The design features sectional door ↑

The design of the gate and features in the design. Various additional mechanisms and supporting electronic systems.

Usually sectional garage gate consists of a spring mechanism, several guiding modules and systems, which balances the very fabric of the gate. In addition, sectional leaf can be equipped with a special mechanism with electronic control, programmed for manual or automatic control open or close, the teams which are served by the remote.

Best sectional lifting the gate to be mounted in areas with limited usable area. Due to constructive features of such gates allow to save large amount of storage space. Panels, which consist of sectional doors you can select any color, there is also the opportunity to individually order the panels in various colours or with a particular image.

Features of production technology and used materials ↑

Special coating to protect from corrosion, operating temperature, equipment of sandwich panels and safety

The production process of panels for garage doors provides their treatment a special coating of polymer materials, which provides long-lasting protection from corrosion and greatly increases the service life. If necessary, the canvas is mounted with a special acrylic window glazing. The minimum temperature for smooth functioning is 50 degrees and the maximum reaches +70 (Celsius).

Safety lifting the sectional door is ensured by a special system of closures, allowing you to automatically lock them after closing.

Warranty: with proper, careful operation and preventive maintenance of such designs are at least 10 years without replacement of units and components.

Preparation for independent installation ↑

The correctness of the measurements of the opening, the tools used in the Assembly and personal protective equipment.

After you have purchased-sectional gate should care about their quality installation. Of course it is best to invite competent and qualified professionals, but if you decide to perform the installation yourself, you need to have a certain amount of knowledge and right tools.

The tools that you need when mounting sectional doors:

- instrumentation and tools (tape measure, level);

- a rotary hammer drill with set of drills;

- auxiliary tools (wrenches, screwdrivers, hammer, pliers);

- personal protective equipment (gloves, goggles and a helmet for the head).

A quality installation is precise and correct measurements ↑

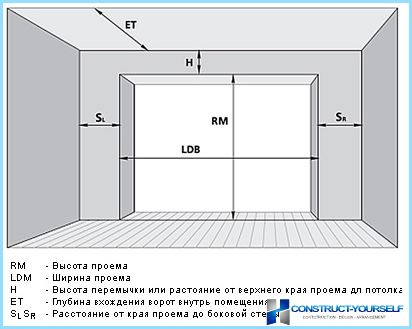

Making proper and accurate measurements, you can avoid a lot of problems and troubles that may occur during subsequent installation

Further, it is very important to determine the distance between the bridge and the ceiling (the height of the ceiling above the door) – this will help you to decide the gate what type of installation you need to purchase. Ideally, the height of the lintels should be about 200 – 220 mm. After done all the precise measurements, you can buy sectional doors for garages with optimal size, or order them custom-made.

Having defined knowledge and reading the literature you can buy quality parts, details and design of lifting and sectional doors on his own project.

Prepare connector for installation of sectional doors for garage ↑

Properly conducted work in preparation of the opening greatly improve the quality and increase the lifetime of lifting and sectional doors.

Efficiently preparing an opening, you will be assured that the design will cost no repair and will last well for many years.

At the initial stage will need to clear the gap from the facing layer, and then reinforce it with a metal frame. For easy installation and smooth functioning will need to create around the doorway, and the free space:

- for parties of 45 to 60 cm;

- from the top of opening to ceiling 30 – 45 cm.

According to instructions from the manufacturer after the preparation of the opening it will be possible to move the circuit Assembly into the opening itself.

Sectional doors for garages are very sensitive even to small distortions and failure to comply with this condition will need frequent repair and replacement of the power units and moving parts.

In order to avoid this you need to accurately identify the site of attachment of the vertical and horizontal profile that will capture and guide the movement of panels. With the help of measuring instruments and level very carefully you need to prepare the mounting location for the bearing elements of the whole structure.

Start the process of installation lifting the sectional door ↑

It is important to note that when you install not allowed alignment of the gate with foam or wooden pegs – you need to prepare a special strip of metal, which tightly and be able to capture all the details.

The installation work must strictly adhere to the requirements of the user and to take into account the technical characteristics of the gates or another manufacturer.

The order of operations:

- self-installation of sectional doors you need to start with fixing the bottom slats, and then attached all the supporting details with observance of the specified instructions in the sequence, and already at the final stage going to the door leaf;

- after all sections are pinned, you should check on the fit of the door, located in the upper part and adjust all of the brackets;

- in the next stage, set and fixed all of the mechanisms that control the gate, also equipped with various bars, handles and locks;

- at the final stage, you need to pull the cables and balance springs;

- to fix in a certain place the drive and install a limiter that will determine the course of the canvas.

Fittings used in the installation of sectional doors ↑

Categorically not allowed when installing sectional doors the use of b/y parts, and all original accessories if it is from different manufacturers should be chosen with compatibility in mind.

People, confident in their knowledge and abilities, intending to independently set the gate should completely eliminate the risk of unreliability of the final design. Most important to collect its doors with original drawings and diagrams. Need to know what the standard equipment from any manufacturer includes more than 25 different kinds of accessories. You should definitely consider, the presence of complete spring strut, angle strut, torsion springs, chain drive, shaft, various mounting brackets, profiles, reels and rollers.

It would be useful to include in the set gate system that prevents the pinching of fingers, insure against rupture of the spring of torsion and the cable breaks.

For more detailed information on the process of installation lifting the sectional door is recommended to watch graphic video