The contents

To make rollers for sliding gates for everyone. But there are certain nuances, without which knowledge creation design is impossible. Moreover, moving parts are just part of the system for a full erection which you want to do a lot of work.

Features sliding gate ↑

Device ↑

An important role in the design of the sliding gate plays the Foundation. It is also necessary to follow exactly the installation steps in order to achieve an optimal result. The roller mechanism is mounted on the Foundation. So it should easily withstand the sash, which may have considerable weight.

The rollers move along the guide beam. In order to achieve reliable fixation, use two supports. In order to design the sliding gate had sufficient strength use welding.

Stand-trolley moves on the beam. Moreover, the upper part is on the bottom of the door. This allows for easy movement from side to side. Modern designs have the automatic transmission, which greatly simplifies the process of opening and closing.

The advantages and disadvantages of sliding gates ↑

The main disadvantage of sliding gates is the cost of their construction. You must use a multitude of items which cannot be manufactured at home. Suffice it to recall the same electric motor, which ensures their movement without effort.

The second significant disadvantage is the additional space required for opening. Unfortunately, some fences have to remodel to build design. But the flaws of the sliding gate over.

Before you make the sliding doors with their hands need to know what benefits they have. First, using them can freely drive a vehicle of any height. Second, done properly, the system is able to withstand 50,000 cycles.

If that’s not reason enough to make sliding doors with their hands, we can recall another one — free choice of material for cladding design. This can be profiled sheets, polycarbonate or even wood. You just need to make a choice.

Another important reason to make it sliding doors is convenience. They are very convenient to use, because for their opening meets the motor. Moreover, if you want to save money, you can do without it, but in this case, you will have to open and close the flap manually.

Do the rollers to open the gate with his own hands ^ a

Without those components you will not be able to do rollers for sliding gates with their hands. To create a robust design is required:

- top rollers,

- limit roller,

- a couple of roller bearings,

- special rail,

- traps,

- plugs.

Each of these elements of the roller mechanism for the sliding gate has its purpose. But only their joint work ensures the normal functioning of the entire system.

Special attention in design should be given the guide rail. It needs to have a sufficient degree of rigidity. If this detail is not sufficiently reliable, in the process of using it just a few more and the whole system fails.

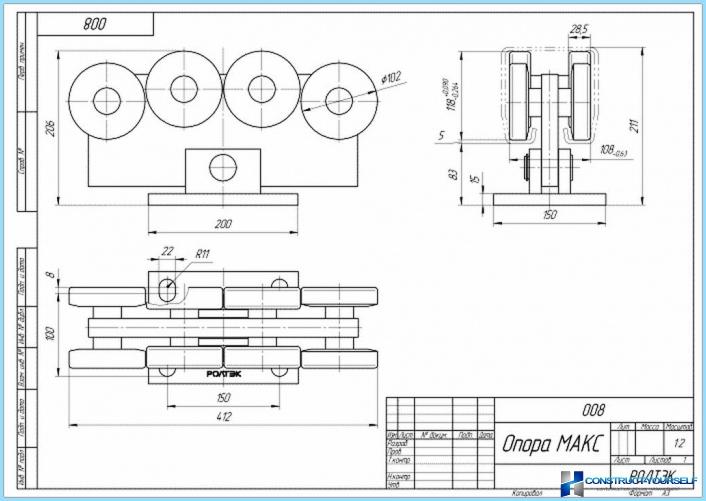

Roller carriage hold the entire weight of the door. Therefore, special attention when creating rollers for sliding gates must be given to them. You need to install quality bearings. Otherwise, every movement of the sash will be accompanied by an unpleasant creaking. Moreover, such rollers are soon to collapse.

During Assembly you must commit each element of the design. Backlash should not be. Otherwise, the system will quickly fail. To ensure a longer lifetime it is useful to use heavy-duty bearings.

For fixation of sash top answer top rollers. It is best to make them of rubber. The plastic in the process, harms the paint. Thickness of steel in structures should be not less than 4 mm.

The end roller and lower trap work in tandem. The main task first to remove the load from the main rollers. The second should be done in such a way that the limit is entered it no problem.

Plugs are installed in the end. Their main task is to protect the rail from rain and snow. All these elements will be enough to make the rollers for sliding gates. But the Assembly design is best considered in the context of creating the entire design.

How to make a gate with a roller mechanism ↑

A list of materials and tools ↑

How to make rollers for sliding gates with his own hands, was written above. But all these items need to be collected. Besides, to create a coherent structure only will not be enough, here is a list of the missing tools and materials:

- corrugated sheet, alternatively you can use a different metal blade;

- the support pipe;

- wrench;

- metal bearing;

- the guide beam;

- steel profiles;

- electric drill;

- of bearing rollers;

- steel corners;

- shovel;

- the actuator and accessories thereto;

- the constituent elements of cement mortar;

- set of drills;

- welding machine.

Only after you prepare all the materials and collect the right set of tools, you can make sliding gates and rollers to them.

Manual ↑

First you need to prepare two holes. The depth of each half a meter. The perfect diameter is 50 centimeters. These recesses will be the Foundation that will allow you to make a homemade sliding gate on rollers.

After preparing the pits for sliding gates on rollers, you want to do with your hands, you should follow the following steps:

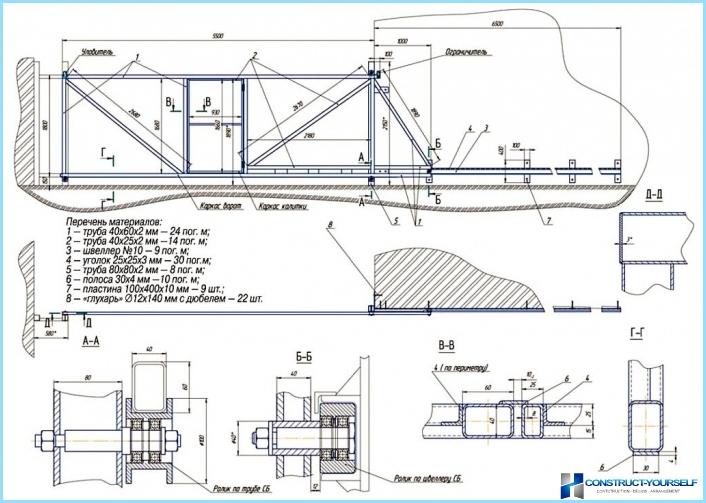

- Mount Assembly support metal pipes. To check the vertical use level of the building. Pour in the gravel pit. Connect the reference tube. It is best for this task suitable metal support. The joints need to brew.

- Make cement mortar. The ratio of cement and sand is one to three. The amount of water should be no more than 25 % of the total weight.

- The resulting mixture pour into the holes. The complete drying process takes about one week. This time is better spend on the creation of the paintings.

- The design of the collar fabric for the sliding gate, which will go on wheels, you need to start with steel corners and profiles. Take them and put them on a flat surface in the shape of a rectangle. Adjust everything with levels and cook with each other. For reinforcement structures can be built, crossover metal profiles.

- Make a reference triangle. He will play the role of counterweight. For this you will need the profiles. Place them on a flat surface, check corners and make the joints using a welding machine. Figure weld to the side edge of the rectangle of the main frame.

- Weld the corrugated sheet. Alternatively, you can use simple screws.

- To the lower ground sash sliding gate rollers need to weld a beam. Only now you can make the roller mechanism.

- Locate the base plate of the Foundation and weld the adjusting strap. After this is done it is necessary to carry out the mounting of the holders for the rollers. Optimal fixation is provided by roller holders. Now the basis of the system responsible for the movement of the gate is mounted. It remains to establish the additional elements.

- The traps are mounted on the supporting pillars. The regulating roller should be installed to the bracket at the top. He will play the role of stopper. For mounting these elements, you will need an electric door. With its help, you need to make holes in the supports. As locking elements to sliding gate roller, use dowels. For greater precaution steel plate.

- After the rollers for sliding gates, you can proceed with installing sash. The canvas you need to insert so that the rollers came in the bottom of the guide. The top and bottom edges should exactly get into all the grooves.

- When the canvas is installed you must check the building level. If you detect any irregularities need to adjust the clips you made with your own hands. To do this, use the wrench. It is very important to check how the sash moves the sliding gate.

- The last step in the installation of sliding doors is the installation of electric drive, which will bring the whole mechanism in motion. Alternatively, you can use a simple pen. The drive must have a concrete base. It is important that the gear got in the grooves.

Now you’ve made sliding doors with his hands. It remains to properly operate the device, and it will last you for years. For example, if you hear during operation of the mechanism squeaking — you need to clean cloth and lubricate the insides. Optimally, this task will handle the grease.

The results ↑

Of course, to make sliding doors with their hands is not easy. But the result is worth it. The design is very easy to use and allows without any difficulty to come and go from the station. Important role it played videos. Exactly how high quality you make roller mechanism depends on the efficiency of the entire system.