The contents

- What is concrete fence panels

- The advantages and disadvantages of concrete fences

- What are concrete panels

- Varieties of concrete panels

- Fences made of monolithic panels

- The placement of the pillars without decorative panels

- The installation of a decorative concrete fence panels

- A combined version of the installation of concrete blocks

Concrete fences of the blocks is a wall of reinforced concrete connections established on a base basis. Such structures, given their attractive appearance, often used in suburban areas. Concrete blocks for the fence are manufactured from high quality concrete, therefore, its functions reliably perform for a long time.

What is concrete fence panels ↑

A team of construction, which consists of pillars made of reinforced concrete sections (panels) connected by embedded elements. Sizes are determined by their purpose:

- As a safety fence.

- To indicate the limits of the suburban area.

- As an element of decor.

For clarity, some types of fences shown in the photo below:

The advantages and disadvantages of concrete fences ↑

Of the strengths of this product are:

- Long service life.

- High show of the fortress.

- Minimal maintenance.

- Easy installation.

- A good combination with other materials.

- The variety of options that mimic natural materials.

- Resistance to atmospheric influences.

- Shielding noise.

Among the shortcomings of the design should highlight the following:

- The cost of the product.

- Required Foundation Foundation.

- A large proportion.

What are the concrete panel ↑

Practical purpose of the fence defines the appearance of the panels, they are:

- solid;

- compound;

- equipped with a reinforcing profile;

- end-to-end;

- with a glossy finish;

- Matt;

- with a relief (unilateral or bilateral) texture;

- with surfaces that mimic natural materials;

Varieties of concrete panels ↑

Concrete wall blocks is a great way to protect your property, and thanks to their large selection and variety, you can make a reality any design imagination in color and texture, shape and height. The height of such structures may reach 4 meters.

Fences made of monolithic panels ↑

Monolithic concrete panels are very heavy, so before installation it is necessary to build the Foundation basis, which requires lifting equipment. These fences are most often used in industry. In the private sector they are used for fencing warehouses, barns and other outbuildings.

Single and double sided panel made of concrete ↑

In a one-sided types of one side of the panel are decorated with the texture of natural materials: brick, stone, wood and so on. In the bilateral options – both sides are the same texture. The difference between them consists only in the cost. The consumer can choose with their capabilities.

Pigmented concrete ↑

Separately should stay on the new panels, made on the basis of pigmented concrete. Value them quite high, but such structures are characterized by even greater strength, durability and reliability. High strength due to special design, which are based on armoratia. Plates are manufactured with the use of more hardy and sturdy concrete class B20, grade F75. This sectional concrete fence extremely massive their weight up to 90 kg.

Block fences ↑

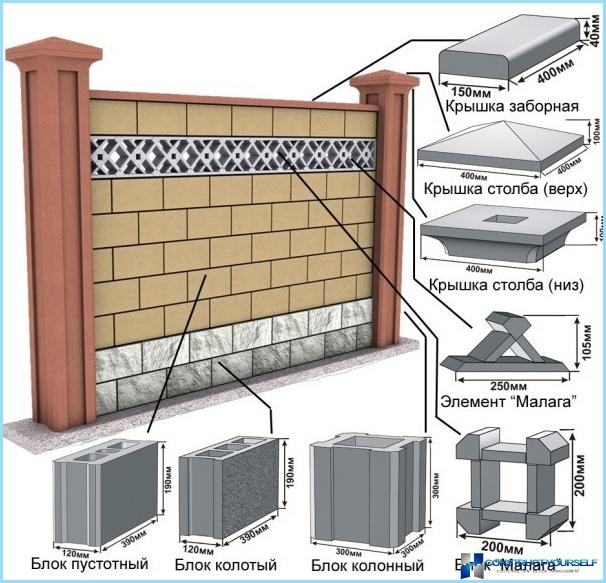

A fence made of concrete blocks is different from the panel fences that set it on a concrete parapet. Units produced plants of different shapes and textures that mimic natural materials: brick, stone, and so on. In the production of concrete blocks used concrete with addition of pigments, so painting such a structure is not needed. By and large they are equal to Eurosatory. In addition, they are perfectly blended with different materials or decorative products, such as forging.

In addition, it is worth noting that such a structure can easily withstand the load of the metal gate. Otherwise their performance is identical to the Eurosatory.

Schematically, a fence made of concrete blocks looks like the following:

In the video, You can watch the process of making concrete blocks for the fence

Decorative concrete fences ↑

Decorative concrete fences from a set of sections today are in great demand. But most consumers know them as the eurosaver is in fact their second name.

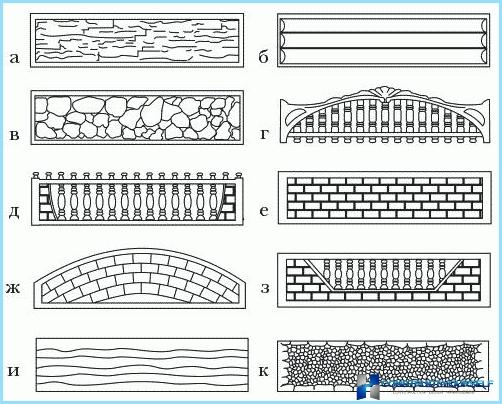

Sections (blocks) consist of several mounting horizontal elements, both one-on-one. Eventually goes solid panel fencing.

Sections can be divided into elements – this ensures ease of transport and ease of installation with their own hands. In addition, these designs make it possible to determine the height of the railing and to your taste to create a unique and design.

The appearance of the panels and slate; b – frame log cabin; in – booth; d, d – decorative up; e, Zh, z – brick; and the Board overlap; to – rubble

In the manufacture of type-setting concrete fences they are impregnated with sealing compounds – it increases the coefficient of durability and hardiness of the product.

Advantages of decorative Eurosatory ↑

Concrete blocks have a number of advantages, notably the following points:

- Limit visual and unauthorized access to the site.

- Concrete blocks are resistant to moisture, temperature, biologically stable.

- Refractory and pozharobezopasna.

- Very easy to install. This gives you the ability to mount the fence with their own hands.

- High durability, reliability and strength.

- Attractive appearance, despite the massiveness of the material.

- Affordable price.

How to install a decorative fence with their hands ↑

Due to the fact that concrete sectional fence – design meaningful, for its installation will require at least three people. Technology of assembling it is very simple, in addition, the experts note that the installation of the concrete fence of the blocks with their hands much easier than the mesh, netting or wood. The only important condition in the process of installation, adhere strictly to the levels. Otherwise your building will last a long time. This article provides detailed instructions for the construction of the fence in photo and video.

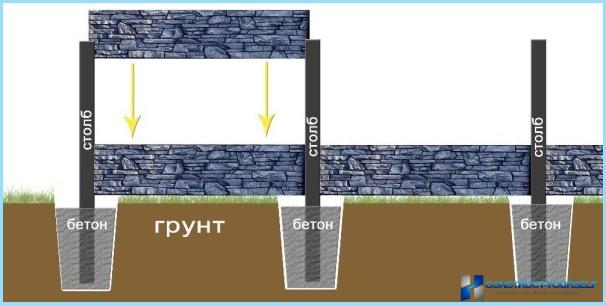

Installation of reinforced concrete structures consists of two basic elements: decorative blocks or panels and metal beams. Before starting work, you need to make the layout of the territory.

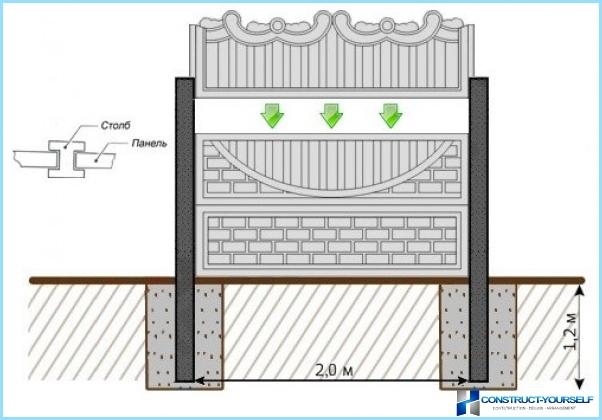

After the markup is produced, proceed to the location of the metal beams around the perimeter at a distance of 2 metres. For beams to firmly hold to consolidate the use of gravel, broken bricks and other materials.

Methods of carrying out installation ↑

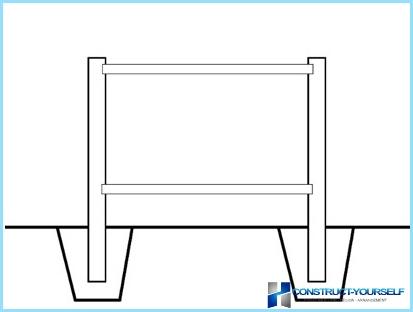

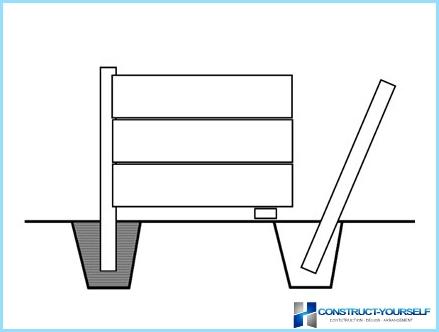

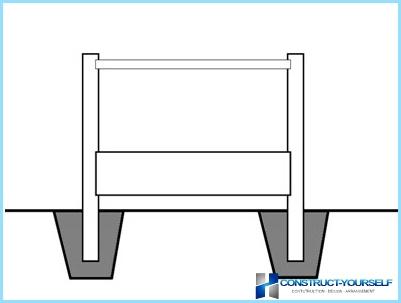

The methods of installation of reinforced concrete and decorative concrete fences are different, the following photo, three of the most commonly used.

The placement of the pillars without decorative panels ↑

The essence of this method is as follows: first, the supports are installed without any sections, they are replaced by wooden templates.

This installation method consists of the following steps:

- Dig the hole.

- Set the beam at a distance of 2 m.

- To establish the level of facility.

- Top and bottom have wooden templates, attach them with a rope.

- Crushed stone and cement mortar strengthened support.

- A day later, the templates can be replaced with panels.

The installation of concrete fence with their hands video:

Installation of decorative concrete fences with panels ↑

This installation method is performed in the following sequence: first install the bearing, followed by the panel, the next post and so on.

A combined version of the installation of concrete blocks ↑

This method of installing concrete fence the items included and the first and second option. The sequence of operations:

- Established first two pillars are aligned to the level.

- Is installed the first bearing, is aligned with the lower section, strengthens the second pillar.

That’s the way around the perimeter of the fence installed all the supports and the lower section. A day is added to the remaining sections of the concrete fence.

Conclusion ↑

Concrete block fence – a rational and practical way to fence its territory from intruders. The ideality of such a choice is determined more and availability at a price equivalent to the setting in comparison with other materials. In addition is and attractive appearance, durability, reliability and strength.