The contents

Neat, well maintained fence with an interesting design, enclosing a country cottage or cottage, not only gives a sense of security, but also provides a beautiful appearance of the home. Whatever intake you choose, it will require support in the form of pillars. The most popular variant of these pillars are metal pillars. The popularity of metal posts due to their affordable price, durability, long service life, easy installation and the possibility of combination with other building materials.

What are the metal poles? ↑

As the metal poles for a fence usually use the pipes having the following types of sections:

- round;

- square;

- rectangular.

Pipe with a circular cross section have a low cost. The height of this type of pipe varies from two and a half to four metres in diameter from 57 to 108 mm.

Pipe with square section is easier to install, and due to the presence of stiffeners are more reliable. They do not need to buy plates, which play the role of stabilizer. The wall thickness of these pipes is 2 to 4 mm.

Pipe with a rectangular cross-section have the same properties as the pipe with square cross-section, distinguishes them only by the performance of.

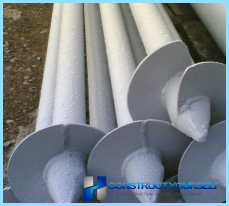

Production of metal poles may be used the method of inner and external hot dip galvanizing, which increases the service life of these products. The thickness of the galvanizing is usually 135 microns. The thickness of the polymer coating often ranges from 65 – 90 microns.

Most rugged and durable are metal poles that have both zinc and polymer coating.

Waterproofing to metal pipe attached metal caps.

The price supports are made of metal depends on its quality and durability and is calculated per linear meter.

Installation of metal poles with their hands ↑

The most practical option for use as supports are metal poles with square section having a size of 60 by 60 millimeters. These supports are easily able to withstand the weight of a fence of corrugated Board with a height of three meters, not to mention more than light wooden constructions.

For installation of support poles, you need the following tools:

- shovel;

- sledgehammer;

- roulette;

- paper;

- pencil;

- building level;

- apparatus for welding;

- string;

- the pegs are made from wood;

- crushed stone;

- sand;

- cement.

The choice of method of installation ↑

In order for the fence was high-quality and durable required at installation to take into account the depth of freezing and soil type.

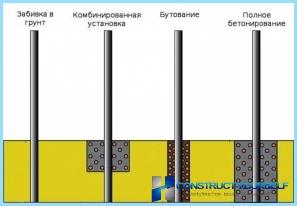

If the ground on which you install the fence, sandy and light, the pillars can be set using a method of screwing or hammering.

The method of scoring is very simple and lies in the fact that the post is hammered with a hammer in the hole. While it is important not to forget to control the evenness of installation, use a level.

Method of screwing more difficult. For this you need to the end of the pipe to weld one or two screws and screw it in the hole. The pipe is better to take a round and thin. When using this installation method, you should definitely think about how it will be carried out the dismantling of supports.

If the ground is marshy, for the installation of metal posts will have to do the Foundation of the belt type, which also needs to be strengthened, and the poles themselves must be carefully protected from possible corrosion.

In the case of heaving soil must use bootovania or partial cementation.

Consider the process of installing metal poles on the example of a fence installed on heaving soils.

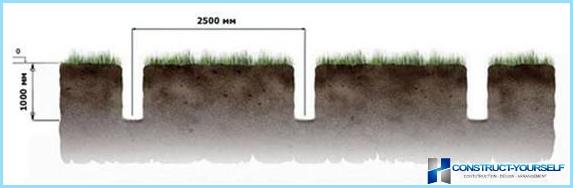

Before the installation of the supports produce measurements of the land and make a plan of the location of the fence indicating it received data, as well as places where there will be gate, gate, pillars etc. Then produce the layout perimeter using wooden stakes and twine. First you need to set the pegs in the corners of the future fence, then in those places where there will be a gate and the gate, then mark the locations of intermediate supports. The distance between supports should be no more than 2.5 meters.

If the distance is more to do, the fence will SAG and lose resistance to wind. If you want your fence was not only strong and durable, but also beautiful, the distance between all columns must be equal.

Where the pillars will be provided to the load, for example, in place of gate and gate is to use the most durable kinds of pipe.

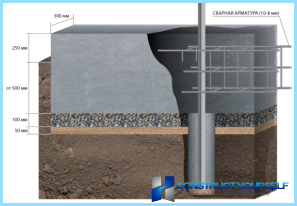

When everything needed for installation is prepared, you can proceed directly to the installation. First install the corner supports. To do this, dig holes with a diameter of less than 40 cm To the bottom of this hole poured the sand, mixed with stones, with a layer thickness of about 5 cm.

Below is a video dedicated to the preparation of holes for metal poles:

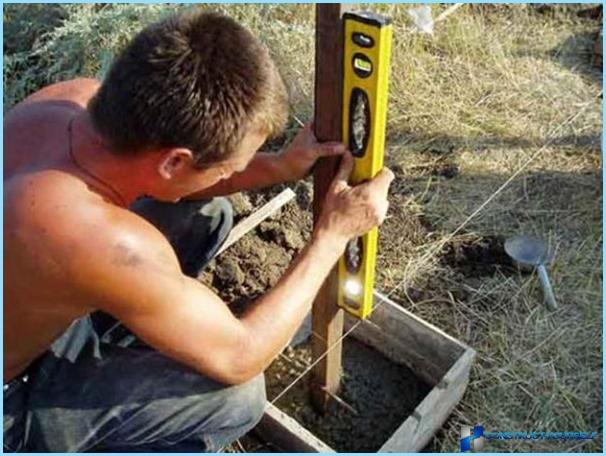

Further in the hole set the post and level it using a level. Pillar fixed method bootovania.

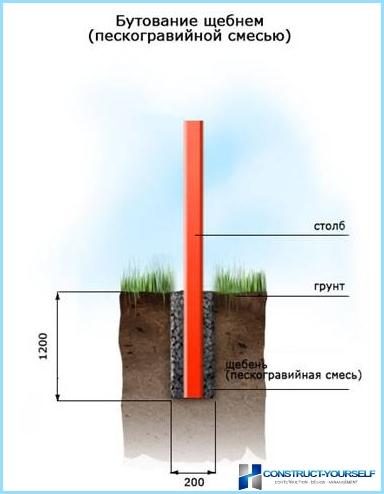

This method involves the following works. In the pit into which you will install the bearing on top of sand-stone mixture, pour crushed stone (with layer of 15-20 cm) tightly and rams his water. Then pour another layer of gravel and tamp it again and watered. So fill layers until the surface of the soil will not remain 15-20 see After falling asleep each layer is necessary to check not whether the banked column. The remaining surface inches poured concrete.

On heaving soils are used bytowanie because the gravel easily pass through groundwater, which are set in motion with periodic freezing and thawing, while using the cement water can not penetrate in result pushes it.

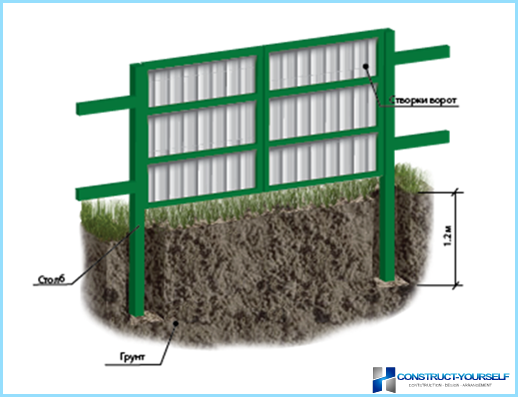

The next step is the installation of supports for fixing gates and doors. As already mentioned, these bearings will be quite a heavy load, so you should choose more strong pillars. Also to these poles were standing as much as possible, they can dig deeper than the rest.

When installed corner pillars and supports for fixing gates and doors, you can proceed to the installation of intermediate metal pillars.

With the installation of metal support poles should constantly monitor their height, linearity and uniformity.

If the support installation is carried out efficiently, the fence will delight you with its beauty and durability for several decades.

More detailed instructions for installing metal support pillars you can see by watching the following video:

Painting of metal poles ↑

The lower part of the column, which will be placed in the ground, covered with asphalt mastic.

To paint the pillars as possible before installation and after. If you decide to paint the pillars before installing, remember that during the installation process, the coating can be damaged, besides painting on all sides is easier to produce in a vertical position.

The dyeing process takes place in several stages:

- Substrates & surface preparation: remove dirt, dust, old coatings.

- Rust removal using special equipment and abrasive paper or abrasive brushes.

- The primer.

- The painting in two layers.

At the present time, there is paint «three in one».

They can even be applied on an unprepared surface without rust removal. But, feedback from people that the colors weren’t always positive. Often, this kind of coverage is poor and the price quite high. Therefore, it is better to trust the proven materials and methods of painting.

You need to use paint that is designed for coating metal products and outdoor applications.