The contents

- Metal fence made of profiled galvanized steel

- Fence are made of industrial rebar or metal rods

- Fence made of profile pipes

Choosing a fence, the Builder usually is guided by the following parameters:

- it must be sturdy and durable;

- easy to install;

- to have a pleasant appearance;

- not require special care;

- to be less expensive.

The above parameters corresponds to a fence made of metal fence. Currently, metal fence presented in a variety of forms and types that even the most discerning consumer will be able to choose for themselves the appropriate option. Due to its diversity, metal fences are used on a wide variety of objects ranging from fence suburban area, or a private home, ending the provision of pedestrian areas and fencing of airports.

Types of materials metal fence ↑

Fences, metal fences can be made from several types of materials. Let’s consider them in more detail.

Metal fence made of profiled galvanized steel ↑

In the production of this type of fence profile galvanized steel is primed and then it is applied to the polymer coating, which ensures the life of the fence to a few tens of years. This type of fencing called eurostudent.

Main advantages:

- with the help of eurostudent possible to make both the deaf and the transparent fence;

- the eurostudent has a huge variety of colors, shapes and sizes;

- the production used high-tech material, which has a long service life, and thanks to the special profile it has high strength;

- the installation of this fence can make even a person with no experience installing similar fencing.

Fence are made of industrial rebar or metal rods ↑

In the manufacture of such fence use the rods of circular or square shape. Make them out of cold rolled steel processed with hot zinc, which provides corrosion resistance. The cross section of the rod for fence may be 12 x 12 mm 14 x 14 mm 16 x 16 mm. the thicker the section, the more solid it will look like a fence, but its cost will also be higher accordingly. If the fence is a fixture, its diameter typically ranges from 10 to 16 mm. Individual elements are welded in the section. Then in the section apply a special coating. If desired, partitions can be decorated with decorative elements.

Main advantages:

- the form of such a fence only limit is the imagination of the designer. This kind of fence forms an excellent combination of bricks and stone and decoration wrought iron elements makes it individual and unique;

- simple, and as a result, and inexpensive installation;

- with proper anti-corrosion treatment and care, this type of fence can serve for decades.

Fence from the profile tubes ↑

When making this type of fencing is used round tube and square section, which are welded to each other and then welded to the frame. Corrosion protection is hot dip galvanizing and polymer coating. These fences are strong and reliable, have a modern and stylish look.

The disadvantages of all these types of fence include the following aspects:

- compared with the installation of a fence of corrugated steel sheeting, installation of fence longer process, because it requires precise measurements when mounting each element;

- the installation of fences, metal fence requires a large amount of fixing materials.

Installation of metal fence with their hands ↑

Calculation of necessary materials ↑

In order to correctly calculate the required amount of materials for self-installation of metal fence, you must perform the following steps:

- to correctly measure the perimeter, which will be held the fence;

- to install what will be the distance between Stettin;

- to calculate the size of gates and wickets;

- to decide how to knit the elements of the fence will be a weld or anchor fasteners, angle or mounting clip;

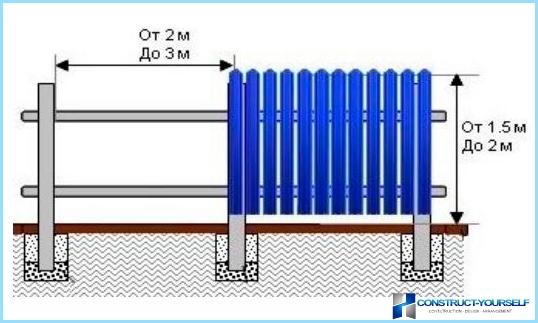

- to calculate the required number of posts, lugs, and consumables (screws, paint, primer). Logs can have a length of from 2 to 12 m. When calculating the required amount it is worth remembering that support for metal fence placed at a distance of 2 – 3 meters from each other and that the load on the joists needs to be uniform. When choosing screws is not worth saving. They should be galvanized with ergonomic caps under the screwdriver. To calculate the required number of profiled strips, there is a special formula:

W = Z ? (1000 mm – RZ) / (133 mm + RZ), where:

W — the number of fence (piece);

Z — fence length (m);

RZ — gap width (mm).

If you install a blind fence staggered the fence must be multiplied by two.

Instructions for the installation of the fence of metal with his own hands ^ a

When you look at a perfectly flat fence made of metal fence, I can’t believe you can install it with your own hands. In fact, is not such a difficult task. So, plan to fence ready, calculations have been made, all necessary materials are purchased. You can go to the direct installation of a fence.

Stage 1. Clearing the area where you will install the fence. Demolition of the old fence. Shrubs, grass and other vegetation are removed. Level the surface on which you will install the fence. At the corners of the perimeter in the ground drive in wooden pegs, and between them pull the twine for marking territory. Mark places where will be placed the support poles. After marking the string removed.

Stage 2. The second step is to dig holes for the supporting pillars. You can use a regular shovel, but it is better to use the drill. It will be much faster and easier. The depth of the pit should be at least 50 cm.

The distance between supports, as mentioned above, should be from 2 to 3 meters.

At the bottom of the hole covered gravel. Then set the column which should be perfectly straight. To achieve this, use of the installation as often as possible building level.

You can drive the prop in the bottom of the pit with a sledgehammer. Installing the pole, the pit is filled with concrete. Since concrete will harden a few days, the pillar needs to be strengthened using wooden sticks-props.

Stage 3. On the supporting pillars set lags. Fastening is performed using screws. The mount can also be made by welding, but then the welds should be treated with a corrosion-resistant coating. Frame for installing fence ready. If necessary, you can paint it in the color of the fence or choose a different color, combined with the tone of shtaketin. If you bought the frame with the fence, then painting is not required. Next, the joists should be marked with the marking for mounting shtaketin. It’s pretty tedious work that requires attention, patience and precision.

Stage 4. Fasten the fence using a power screwdriver and screws to the joists. Distance between shtaketiny depends only on your desire. But most often it is in the range of 50 -100 mm. the Main thing is that the distance was around the perimeter of the fence is strictly the same. Tie should be very careful not to damage the polymeric coating of the fence.

If you decided to make a double-sided fence, attach the fence from the inner side in a staggered manner, then you should leave a gap between the slats 35 mm. It will give the fence the appearance of lightness and transparency.

In addition to the fence, you can buy a cornice, which will improve its appearance. It is attached as well as the fence using screws.

Stage 5. The installation gates and doors. They are secured on the supporting pillars and set all the necessary hardware (latches, bolts, etc.).

Installation video of Eurostudent:

This works on the installation of a fence of metal fence is completed. Installation of metal fence is a fairly simple process, and the result is impressive. You get not only reliable and durable but also aesthetically appealing fence your plot.