The contents

High quality wiring in a private house, in addition to accomplish the functionality required to provide high level of security for everyone in the room lives, particularly for the owner of the object. To ensure all these parameters need to involve specialists, wiring in a wooden house which is the main activity. The second option is to perform all operations with their hands, minimizing costs in time, effort, materials and resources. But when you decide not to use masters, you need to take into consideration that the electrical wiring in a private home will require compliance with all the rules of installation and construction works.

The complex of works on laying of electrical ↑

To bring together all the operations that includes wiring in a wooden house with his own hands, step by step instructions are presented in full, should consider the detailed sequence, according to her works:

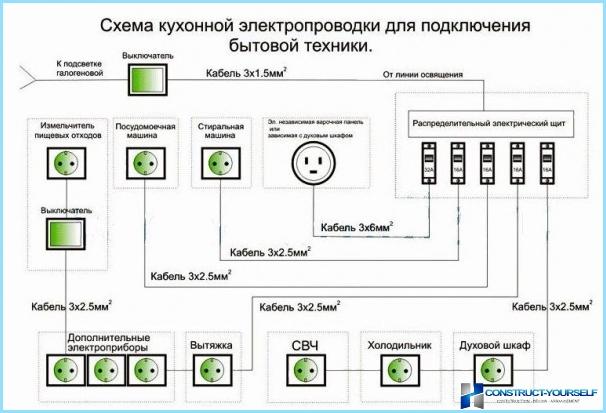

- The design of the operation, which is performed analysis of performance parameters of the installed equipment used electrical machinery

- Selected cable products, electronic equipment, calculation and installation of items marked in advance on a load for the billing period.

- In a room of the house connects the introductory switch automatic type, and binding of electric meter mounting distribution equipment, special shield.

- Laid the bundle of cables, is the wiring at scheduled points, according to pre-established project plan.

- At the next stage of works are the required number of switches, sockets, lighting and other equipment.

- Mounted mandatory set of elements of the grounding, ouzo, and other elements of protection systems that are relevant when serving customers.

- At the final stage of works tests, health check equipment, all systems, analysis of the functioning of assemblies, cables, the correctness of the liner.

Design design ↑

At the design development phase, special attention is paid to the analysis of possible loads, which takes design, each individual element in the process of operation. Selected the type of switch based on the need for later use, therefore, is characterized by regulations of the standards. Necessarily taken into account the number and the name of the installed equipment in the premises, their subsequent joint use and quality operation. Be sure you analyze the congestion in the subsequent work, which causes the need for correct performing of works for designing systems.

The choice of power system ↑

When running wiring in the house with his own hands step by step, it is important to pay attention to the choice of the lead-in cable. The main parameter in this case is the analysis of the maximum power supply system. Changing the entire set of installed cables is increased to the required parameters the value of the switches. The next stage, the replacement of the lead-in cable in which it is important to calculate its cross section. With insufficient cross-section, applying to the equipment a large load, the ignition which will lead to system failure and will require revision of the entire electrical system. Together with the replacement of the lead-in cable wiring in the house requires installation, electric meter, its subsequent sealing.

Wiring in a wooden house with his own hands, in particular, installation of the system input circuit breaker provided protection for a group of machines in case of short circuits arising in the system. But it is important to set up the power supply so that the maximum load she worked efficiently and smoothly. If the object is powered from the mains three-phase type, set the appropriate switch. When it is necessary to equip single-phase network, the electrical wiring in a private home provides for the inclusion of one or two elements.

The procedure, which involves wiring in a wooden house with his own hands includes the mandatory installation of the switch after the meter. Alternatively, you can try to set the unit to meter, but not necessarily at this stage to seal the latter. Set opening machine, the system of the RCD in the plate, the metal body is additionally grounded. The instrument is mounted on the rail, installation is carried out in full accordance with the existing scheme..

Wiring in a wooden house ↑

Electrical wiring in the house with his own hands (cable) is laid as follows:

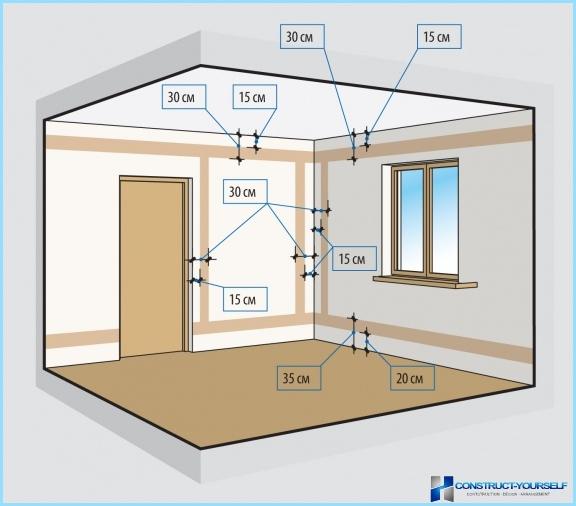

- Before starting work, be sure to choose a mounting and alignment is performed installations, junction boxes, distributed the subsequent space for mounting sockets and other equipment switches. Necessarily separately calculated the space for the installation of lighting.

- Strip in the metal sleeve, or a pipe occurs when it is planned to carry out the complete covering of walls and the presence of emerging Postings will be visually unattractive element. Plastic gofrotruba in this case you cannot use, otherwise may damage, failure due to mechanical impact. Gofrotruba may also be ignited, which really occurs in exceptional cases.

- Preparing the cable route, the master also performs grooves. Regarding the connections of the elements are special junction boxes, that can be obtained easy access to the cable after you complete the wall.

- Wiring in a wooden house, the rules of which are caused by safety standards that require penetrations through walls, through the use of metal sleeves installed in the construction of plugs. If necessary, the mounting sockets shall be installation of casings of a different type.

- Tubes are selected strictly on the condition that the inner diameter of the structure is filled within not more than 40%. The optimal solution would be a copper pipe, which though they do not boast of cheapness and availability, but, nevertheless, perfectly amenable to bending, perfectly handled their sections. In this case, the slices are cleaned and polished, which is done gently, without deforming the structure. Metal hose for electrical wiring in a wooden house specially set for the purpose of additional protection of equipment, individual items from damage.

- Structurally, pipes are fastened to the wall surface through the use of clips selected according to the diameter of the equipment, or using special flaring copper pipes, installed inside the sleeve.

- The cable in this case will be placed via drag-and-dropped in a special box pipe, thus immediately checked the fit it to the hull. This will ensure the exception of damage to the insulation during laying of cable products.

- Split the cable in the boxes is left about twenty inches, and this is the main condition by which a qualitative and operational rewiring the whole structure. Connection of the cores is performed by a special set of caps.

- The cables cut and after that, each output is connected to every switch, outlet, or an automatic switch. What is important, must be respected labeling of each cable and connector that will allow you to connect the wiring efficiently and effectively, without the likelihood of exit from the system design.