The design of stoves, which became widespread in the 19th century, has not lost its relevance in the present time. At the dawn of the last century it served as the main method of heating in residential areas where it was not possible to establish a stationary furnace. With the advent of Central heating stoves the popularity declined, but during the war, and just military in the field, using such ovens are.

The types of improvised furnaces ↑

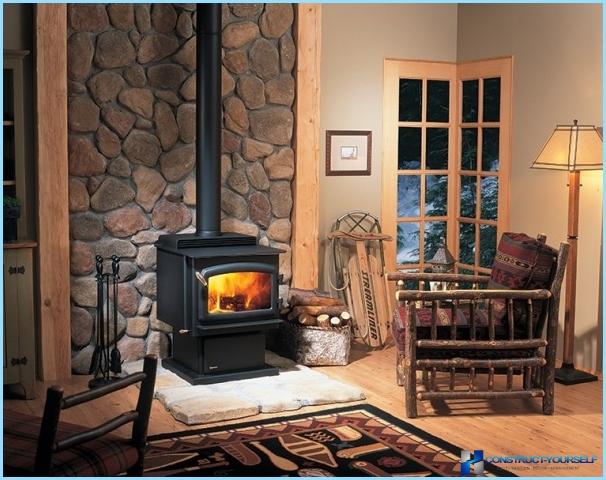

The selection of the most suitable designs of stoves depend on the place and goals of its operation. The garage is your second home and you spend it all free time regardless of the weather outside? The best solution would be to make a furnace that uses waste fuels. Decided to get a stove at the cottage? Then it is better to provide option with the possibility of cooking. If you plan to use the stove outside, the appearance does not matter, but for the house it is advisable to make a beautiful heating source. Depending on the destination, stoves can be classified into the following types:

- the device is equipped with a surface for cooking;

- long burning ovens;

- a larger effect of heat transfer.

Often for the manufacture of stoves do not require significant financial costs for the purchase of materials. Craftsmen offer to make the furnace of the following scrap materials:

- metal box;

- a gas cylinder;

- cans for milk or other metal object of cylindrical shape;

- suitable metal sheets.

In the standard elements of stoves includes:

- chamber for burning fuel;

- grate;

- the office for ash;

- pipe-chimney.

Individual designs of stoves may differ from conventional standards, to be refined and complemented by individual elements.

The device at spent fuel ↑

To do in the garage with your hands using the stove for heating spent fuel – a double benefit. Getting the desired heat, the owner of the furnace at the same time disposes of waste. In a device of similar design included two tanks, connecting pipe and chimney. Tanks for stoves, you can make cylindrical or rectangular shape. Any construction is preceded by a preparatory phase, which includes designing future furnaces.

The reservoir sizes range from estimated fuel. To make the connecting pipe must comply with certain proportions: 10 cm – minimal diameter, the length greater than the diameter 4 times. Around the entire circumference and length of connecting pipe is required to make holes in the quantity of 50 pieces. It is located between the two tanks. The height of the chimney of the furnace – not less than 4 feet.

What else need to do for a stove? The lower reservoir is equipped with a lid with two holes for supplying oil and air, bottom mounted legs. After that, all of the stove (2 tanks and connecting pipe) are subjected to thorough welding.

The principle of operation of the stoves to simulate is the following:

- in a cold furnace through the pipe in the bottom of the container is filled with spent fuel;

- then in the hole served firelighters;

- if you are working you hear a small buzz is normal process.

If you make the capacitance large enough, the top can be used for heating food or water.

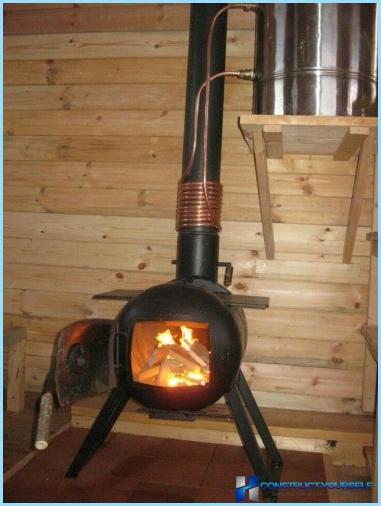

The design of the gas tank ↑

Being the owner of a gas cylinder, the stove with his hands – the right decision. Thick walls allow you to create mobile and durable construction. To make the furnace is available in two options – placing the cylinder horizontally or vertically. Let’s consider in details the second option stoves. Manufacture takes place in several stages:

- in the center of the cylinder marks the entrance to the combustion chamber;

- stepping back down 10 cm, is applied to the circuit for the blower;

- to make the holes is using a grinder;

- between the two doors drawn closed line on which the cylinder is cut by a blowtorch into two parts;

- to the bottom of stove in the center of the cut is welded grate through which the ash of the burnt wood will fall into the ash pit;

- after fixing the lattice gas tank back is connected by welding;

- in the area of the valve for proper furnace operation it is necessary to make a hole with a diameter of about 20 cm, which is the tube performing the function of the hood;

- left to do for stove legs, and the bulk of the work is completed.

If you belong to aesthetes and want to impress their tidiness friends who came to visit at the light, you can dissect the design of high-temperature paint.

This stove is suitable only for heating purposes. If the tasks included warming up or cooking, you need to make some adjustments in the upper part of the furnace. This is to cut the tops welded inside the bars to be able to install the dishes. To make a hole for the pipe, a must for any stove, you need the side in the top of the device. In the moments when the stove is used only for heating, grate for cookware lid, made of cut parts of the cylinder.

Rectangular stove ↑

For country houses are more suitable rectangular oven stove. For effective and long-lasting use it is important to make the heating device from properly selected according to the thickness of the metal sheets. Too thin the material will quickly burn out and the stove will break down in no time, and if the oven is too thick, a long warm up will significantly reduce the effectiveness of its work. The optimum thickness of material for walls from 4 mm. the wall is better made of metal of a thickness exceeding 10 mm. For rectangular stoves will also need a grate, a pipe for drawing and places to stand. Proper design will ensure economical use of fuel and the ability to adjust the air flow.

You can make a furnace similar to the gas cylinder with a vertical, but it is better to upgrade the device to increase efficiency. In this case, in addition to the body of metal of greater thickness, it is necessary to make a partition intended for installation in the top of the fuel compartment. A small improvement for smoke creates a kind of labyrinth, slowing the process of cooling of the stoves. At the top, in addition to the hole for the chimney, it is recommended to make another hole that allows you to cook food.

The furnace interior is divided into 3 parts – the ash pan, furnace and «maze» for smoke. Between the first two sets the lattice on which is placed the solid fuel. If you want to do it with your hands, make sure there thick sheet steel. Strips of width 2.5-3 cm and a length corresponding to the dimensions of the stoves are welded to metal rods with a diameter of 1.5-2 cm at a distance of 5 cm from each other. Experts recommend to make a removable grid for possible cleaning or replacement. For mounting inside the stoves previously throughout the length of the welded corners.

The next stage is to make strip supports, welded to the side walls of the furnace and you can go to the manufacture of doors for the firebox and ash pan. Keep them in the basic design of stoves will help hanging loop. In conclusion, we should make a pipe-chimney.

Long burning ovens ↑

Firewood in standard devices fail quickly and require regular additions. But the craftsmen offer to make oven stove long burning especially necessary for heating the cottage. Its design is radically different from the species described in the previous sections. Required for the manufacture of a cylindrical container made of metal of suitable thickness. The process of creating the stoves long-burning involves the following steps:

- the upper portion is cut, thereafter, it performs the function of the lid;

- at the top side of the stoves should make a hole for the hood;

- the fire through the top hole, not through the side doors as standard furnaces;

- then you need to make a metal circle, with a diameter slightly smaller stoves having a Central hole;

- in the prepared aperture is inserted into the pipe, surpassing the furnace height and performing the function of a blower, to maintain the combustion process at the expense of oxygen;

- in conclusion, you want to make an opening in the lid of the stove, providing free, but the tight passage of tubes-blower.

In the finished device is initially immersed in the fuel. When firewood good will inflame, top, immersed disk with an exhaust pipe, then closed the lid. The principle of furnace design is the insufficient supply of oxygen, with the result that the wood does not burn quickly, but slowly smolders, providing heat for 8 hours.

Features of manufacturing ↑

To increase the efficiency of the stoves, it is advisable to make the chimney, the maximum passing around the room. The horizontal position of the drawing on a particular area allows the smoke to further ensure the supply of heat, and not to go immediately out.

Taking care of the safety measures, the experts recommend to do around the stove box, to prevent the risk of burns. This will require at a distance of 5-10 cm from the oven to set additional plates. The air gap will not allow significant heating of the boxes and provide a comfortable feeling when being around a stove. This protection best for rectangular furnaces, with cylindrical shape design is impractical.

Individual craftsmen fit the stove for the two fuels. Addition construction infrared burner allows you to make universal stove running on wood gas. Showing imagination, some create models that serve as an original decoration of a garden or are able to heat the water in the tank, located next to the stove.

The advantages and disadvantages of stoves ↑

Having studied the advantages and negative sides of the design, we can make a conclusion about the necessity or lack thereof to do with their hands stove. The main advantages are as follows:

- the possibility of using cheap raw materials: for heating suitable sawdust, wood, peat or coal;

- small financial costs to make the device purchase ready-made furnace will cost much more;

- compact size design;

- the ability to operate the stoves without capital chimney;

- easily moved to another location.

Negative aspects include:

- mandatory protection on the floor in case of falling embers;

- quality heat insulation wall surface near the stove;

- the fiery wall is a source of risk for burns;

- quick fuel consumption, heating is carried out only with regular addition.

As with any heating appliance, stove has certain advantages and certain drawbacks. So before you make your hands comfortable oven, consider most suitable for your design purposes, then the result will please you for a long time.