The contents

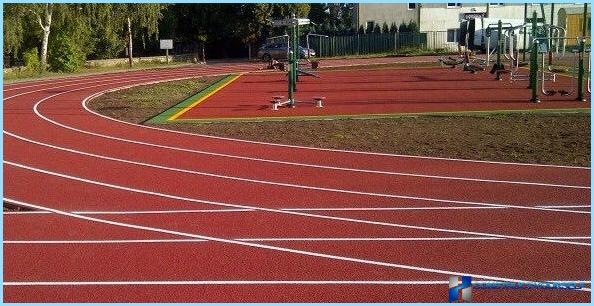

While entertainment and various games the children have shown remarkable activity, often forgetting about the security measures. Therefore, it is important that the place where he walked and children played – particularly playgrounds, was elastic and soft to the sudden drops the child was not injured.

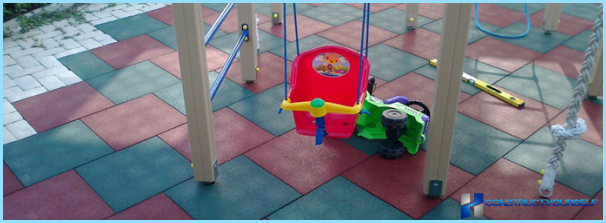

Over the last few years began to use the new rubber flooring for playgrounds, made by special technology. This material is capable to prevent numerous injuries in children that occur in the fall and the friction of the parts of the body of the child of asphalt, concrete, tiles or gravel. This was achieved through the various components, which prevent slipping, doing rubber crumb is soft and durable. Observing certain technologies and recommendations, very easy to install rubber flooring for playgrounds with their hands.

Crumb rubber to cover playgrounds ↑

What made crumb rubber for playgrounds? This material is made from used tires which have been in operation for a long time. These tires are ground into crumb rubber, which further make the coating for children’s playgrounds.

The advantages of coatings of rubber crumb ↑

The prevalence of the use of coatings of rubber crumb explained by the fact that it has many advantages:

- Security – rubber has resilient properties that enable the production of safe coverings for sports, active games and entertainment. This surface may be smooth or rough, which prevents slipping and falling even under rainy weather.

- Sustainability – crumb rubber does not emit harmful substances and components. In addition to the rubber in the composition includes polyurethane, is required for good coupling to the layer on which to creep baby, and safe dyes. This material is environmentally friendly and safe even for kids.

- Quick and easy installation – rubber flooring for playgrounds is easy to mount with their hands, which will save a considerable amount on the services of specialists in this field and will help you to gain the essential experience. For proper installation, follow the instructions of the manufacturer.

- Diversity – a covering for children’s playgrounds available in several colors, sizes, shapes and types.

- Resistance – this material is not afraid of such weather factors like snow, frost, rain, hail, ultraviolet rays, temperature extremes, and mechanical damage.

- Durability – coverage of children’s space to play rubber can be used up to 10 years, as rubber has a very long term collapse.

- Purity – to maintain cleanliness at the site it is only necessary to wash the surface, because in spite of the porosity of the crumb, dirt does not penetrate into the flooring.

- Hygiene – rubber is not prone to accumulation of germs, bacteria, insects, weeds, and decay.

- Aesthetics – into crumbs add safe colored dyes that allows you to create drawings and patterns on the pads.

- Easy care – requires only occasional cleaning or vacuuming – what to enable to restore the appearance of the material, which was originally. Through baby will not grow grass and any other plants that allows for a long time to forget about the weeding game footage.

- Permeability – this material does not accumulate moisture and puddles. Water seeps through small pores in the lower layers of covering, and then goes into the ground.

- UV resistance – the material is robust and not affected by sun exposure, allowing you to keep the original color for a long time.

Disadvantages of rubber covering ↑

In this, as any other material there are some disadvantages. The main disadvantages include its Flammability. This material is forbidden to be used near places where there are open flames, as the rubber can rapidly catch fire and smolder for a long time.

Not unimportant disadvantage of rubber flooring is its high price. Crumb rubber among other coverages cost is the leader, but this disadvantage is offset by strength and its durability.

Methods of preparation of rubber crumb in the home ↑

The first method. The simple grinding of used car ramps. For this process you must have an axe, scissors, knife, and hatchets. When you have enough materials, you can begin the grinding process. If you want to do baby stingrays, you will first need to have to remove the metal cords. The next stage is cross milled to the desired size. For the manufacture of 1 m? chips of a thickness of one cm, it is necessary not less than 8 kg of rubber. After grinding the rubber crumbs to mix with polyurethane glue, and then applied to smooth, prepared surface.

The second, easier, method of grinding car ramps – grinding under the influence of temperature on the rubber from -70 to -80 C. In this state, the rubber is more brittle and pliable.

Types of seamless coatings ↑

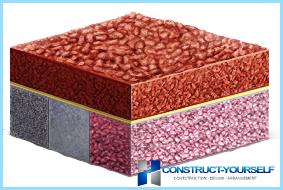

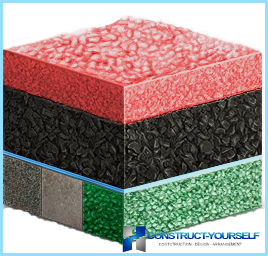

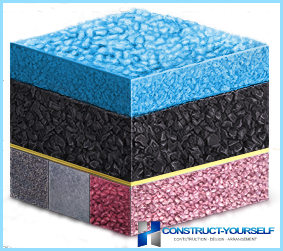

Currently, the manufacturing plants produce rubber crumb of several types. The most popular are the rolls – crumb, frozen and sliced strips of different widths or lengths. Next is the tile that is cast in various sizes and shapes and, finally, a seamless coating – mixture, which prior to installation should be diluted in certain proportions according to the instructions and pour the surface. This material can be used in both closed and open spaces.

- Fills sports and children’s playgrounds “Cover Epdm”10 mm has a difference from other types of seamless material with various color painting. Cover this brand for as long as you keep the brightness of colors, are reliable, safe and anti-slip material.

- “Cover the Base” 10 mm – safe, durable and universal coverage for games playgrounds. The coating thickness is 10 mm, which provides elasticity, softness and anti.

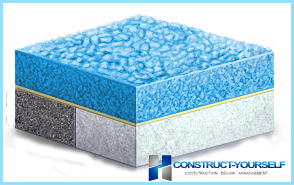

- Rubber flooring for playgrounds “Double Cover “of 15 mm. This flooring is endowed with a double soft, double layer: the bottom layer of the rubber substrate up to 10 mm thick, upper – primary with the addition of the dye with thickness up to 7 mm.

- Seamless coverage for children’s playgrounds “Cover Double Epdm” 15 mm endowed with a special softness. Differs from the others by its special color palette. Consists of 100% rubber. The color of the material will not be erased and always remains colorful and bright. Is a safe covering for children.

Coating technology platforms rubber crumb ↑

Cover with crumb rubber in rolls ↑

Before you lay the material, the area must be prepared, namely to clean the surface from grease, dirt and dust, and if it is concrete, it must be sanded, sweep or vacuum. After that, the surface of the lining applied glue of polyurethane, stacked rolls of the desired size and stuck the joints with glue.

Coating rubber crumb tiles ↑

To cover with rubber crumb tiles to align the coverage that will be under the tile, clean it from grease, dust, dirt, sand and gravel.

If the prepared surface has a roughness, it is recommended to clean with cement floors. When mounting surface on the street, for example, in the stadium or other sports ground in the yard, you need to make drainage, the angle of the surface which should be 20 degrees.

With a roller on the surface of polyurethane adhesive, tile is laid.

Installation of seamless coverage ↑

For site installation, seamless coverage with their hands should do the following:

- To prepare a place that will be fill. This coating must be asphalt, wood or concrete.

- The base surface on which will be filling must be sanded, align, clean from dust, dirt, grease, oils, and any other small particles. If the substrate is concrete, it is recommended to moisten, sbryznuv water, Polish and vacuum.

- Laying seamless coating should be carried out at a temperature not less than +6.

- The lining must be treated with special primer and allow time to soak in for one day.

- The fill surface outdoors is best done on a warm Sunny day that the rubber can dry in the shortest time.

- During preparation it is important to observe the proportions prescribed by the manufacturer, as this can affect service life, seamless coverage. Must be mixed with a mixer or other convenient containers dry crumb rubber, polyurethane glue and dye.

- The thickness of the fill coverage should be about 8 cm.

- After the Bay cover, it must be leveled using a roller, greased special antiadhesion.

- To thicken the mixture for two days.

- For longer preservation of the beauty of the seamless coating can be applied coat of varnish velour cushion.

The main requirement to the playgrounds for children is their safety. Planning to build a place for recreation and entertainment, it is important to choose the right antitrauamtic coating playgrounds.