The contents

Paving the millions of owners of cottages and country houses selected as a material for the improvement of their land: the device of pavement and walkways, paving, playgrounds, recreational areas and places allocated for Parking of vehicles. Sidewalk tile is almost perfect for these purposes: reasonable price, ease of installation and subsequent care of her, the possibility of simple and quick replacement of damaged areas, frost and wear resistance, good performance, a wide choice of textures, patterns and colors. Environmentally friendly building material. Add to that the constant appearance on the market of new types of paving slabs with a previously unexpected and attractive opportunities (rubber paving slabs, polymeric sand tiles, tile surround with colored drawings), and will understand the reasons for such popularity.

The choice of tiles ↑

We are not talking about choosing the color, pattern and texture. In this matter every customer is guided by their preferences and their vision of the design of the site. We are talking about performance characteristics of this material.

As you know, there are two ways to tile production: the vibratory casting and vibropressovoe. Advantages of the first method is the variety of colors, a rich selection of existing forms, in which in the manufacture of paving tiles is filled with a mixture, and the opportunity to make an individual order for a material of almost any configuration. If you need unique, exclusive design which you want to con the relatives, friends and neighbors, you need vibrocasting tiles. It should be remembered that it is relatively short lifespan (about 7 years) and limited in comparison with vibropressed tile performance. It is not suitable for paving areas with heavy load, including car parks.

Vibropressed tile (of course, the appropriate type) can be used for any purpose, including for paving driveways and Parking lots of vehicles. Some types, primarily granite paving stone used for paving roads. Such a pavement can withstand the weight of heavy vehicles. Paving slab made by means of vibrocompression, has excellent performance characteristics, wear – resistant, it is long service life (marketers say about 200 or more years. The technique, known since the time of Nasreddin Hodja, which is reasonably believed that during this time, someone involved in the dispute will die. But, in any case, in our age of longevity vibropressed tiles accurately enough). Improvement of the equipment and a consistently high demand for paving tiles allow manufacturers to offer customers new varieties of this material. And if until recently it was possible to clearly separate: the original design vibrocasting tiles, reliability and performance – vibro, today this distinction disappears, and wash her producers vibropressed tiles.

The site plan, the layout of the tracks and platforms ↑

Plan of the site, which will paths and equipped areas. After you have a plan, pass the selected position and with the help of pegs, tape and cord make markings and measurements. It’s very fun, just imagine that you are a prospector in the Wild West, and stilbite new gold claim. The width of the tracks define on the basis of square footage. It is believed that the ideal track width should be 1 meter. Practice shows that not every area can be allocated for the track in the area, and that the width is 0.5 meter quite comfortable. You decide.

Materials and tools for installation ↑

Materials we need:

- Paving slabs (the seller can specify the number, showing him the site plan with dimensions). For walkways and recreation areas, suitable material with a thickness of 40-50 mm, for Parking and access roads – 60 mm. This thickness is enough to provide secure Parking and equipment access routes for a large SUV.

- Curbs.

- The dry mixture M150.

- The gravel fraction 10-20.

- Sand.

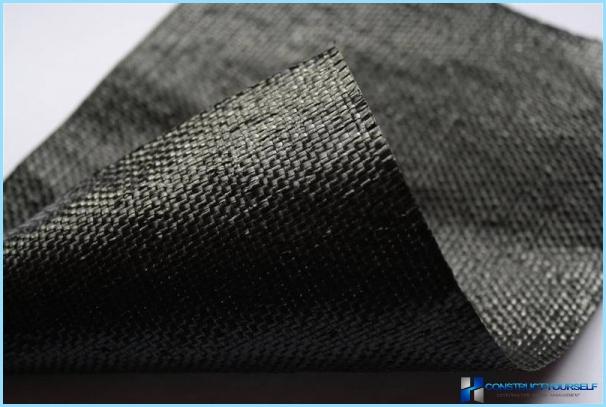

- Geotextile.

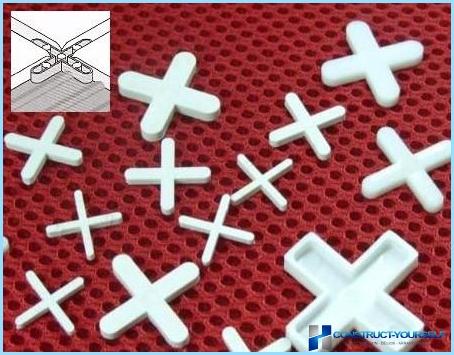

- Plastic crosses for laying.

Go to the tool:

- Shovel bayonet.

- Car.

- Manual compaction.

- A wooden mallet or a rubber mallet.

- Trowel.

- An angle grinder with a diamond wheel. It is needed if you need to cut paving slabs.

- Building level.

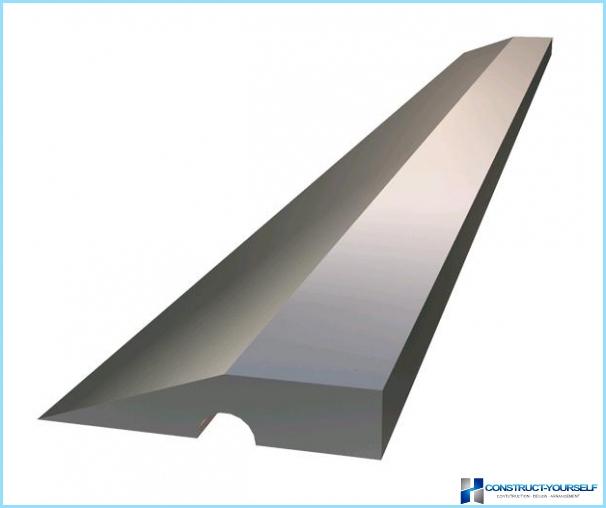

- Long rule.

- Two pieces of pipe of the same diameter.

- Pegs of wood or metal.

- Cord-ryadovka.

- Hose for irrigation with rasseivatelei.

- Hard brush.

- Rake.

- The knee pads. They need you will appreciate after a few hours in the most comfortable position.

Everything is ready, you can begin laying tiles.

Substrate preparation ↑

The markup made by digging a trench. We need to remove the sod at least 20 centimeters deep. Carefully remove from the trench the roots of the plants. Take out the soil so that the trench was with a lateral bias. So we will be able to achieve water runoff from paving.

After completing the excavation, we begin the bottom of the trench is carefully compacted. The builders for this purpose, a machine for ramming, but if you have this in the household, you can make a manual or just take a small log. Make grooves for the installation of curbs.

Many believe that the size of the tiles is known, the width of the seams between the tiles are roughly known, so to set the border is necessary at the stage of preparation of the ground. The logic in this. As is, it is experts that to accurately determine the width of the paths in advance is impossible. Sidewalk tile is not ceramic for bathroom or kitchen, the thickness of the seams will not be identical and in the end the border will have to move. An opinion worth listening to? To the first. Only we must not focus on your eye, and on a special plastic crosses. Used when laying ceramic tiles. Take a solid cross 2 mm.

Cover the bottom of the trench with geotextile. Now no weed to the sun through the track to break will not. Fill geotextile with a layer of gravel thickness of about 20 cm, wetted with water and starting to stamp. Tamp intensively, we need to after this surgery left a layer not thicker than 15 cm.

When laying paving slabs on gartsovku (a mixture of sand and cement) or sand over the crushed stone is a sandy pillow. If you want to lay on a concrete Foundation, gravel pour a solution prepared from a dry plaster mix. After solidification of the solution you will get finished concrete floor.

Proceed to install curbs in the groove. Pre-fill the groove in the gravel, stamps, alignment, laying in the groove of the grout and install the curb. Check the horizontality of the building level. Remember that the height of the curbs should be lower than the height of the surface of the laid paving to prevent the flow of water from the track.

Cover the compacted gravel with geotextile and pour on top of the sand. We need to make a sand pillow. The geotextile prevents the ingress of sand into the gravel cushion and its clogging, because the gravel will perform in «pie» track drainage function. Level the sand using the rake and stamps. Then profusely to the formation of puddles on its surface. When the sand dries, making the surface completely flat. Use improvised «beacons» from pieces of pipe of the same diameter. Pipe countersunk head in the sand and make the surface smooth. As do the cement screed. The base.

Do not forget about the main drainage. The drain pipe wrapped in a single layer of geotextile and placed in a shallow groove directly behind the curbs on one side of the track. In this case, the geotextile also will not allow the particles of soil and sand to get into the drain pipe and clog it. Create when laying pipes slope towards a drainage pit. Laid so that the drainage is not conspicuous. A temporary way out of the situation without laying pipes for the organization of drainage can become a shallow, open groove with a bias to the well. It will have to be cleaned regularly, but the discharge of water from paths it is possible to arrange.

Technology laying on the sand pillow ↑

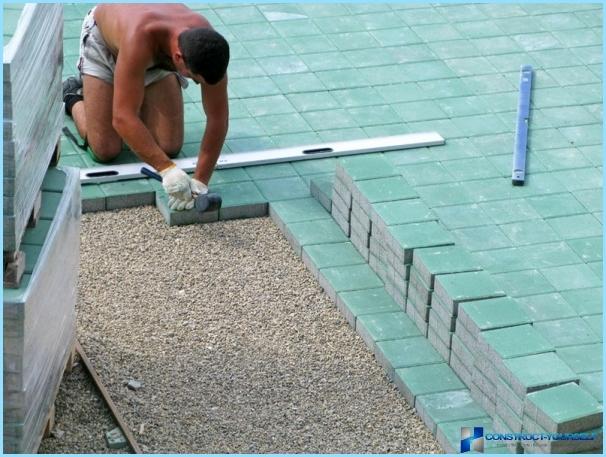

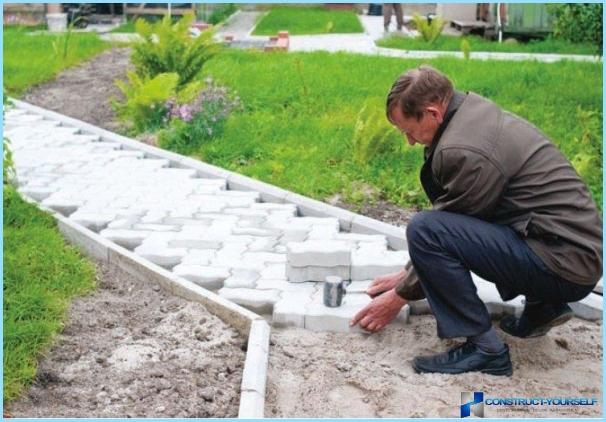

Start laying. Bag of sand should be well compacted and leveled. Lay the tile. Starting from the curb and move in the direction «myself». Lightly beat it in a Foundation of sand and align the strokes with a wooden mallet or hammer with a rubber head. Builders use for this purpose plate. When a large amount of work in your area by laying the tiles with their hands, it is advisable to rent a plate compactor for hire.

Constantly monitor the level. Applied building level along the rows, and diagonally. The other side of the tracks, where will drain the water and along which is laid a drain should be placed at an angle of about 3% to the opposite side.

Every two series stacked paving slabs apply a rule (or flat bar) and a percussion mallet, flatten the gaps.

After completing the laying, fill all gaps with a dry plaster mixture and abundantly watered. The diffuser on the hose we need to get the rain effect, and not the jets that wash the mixture from the clearances. Before watering sweep away with the track surface all the debris and remnants of dry mix.

Leave the finished track for a while without load to the mortar in joints has hardened.

Remember that consumption depends on the installation method. So, for a diagonal installation, the consumption will be more.

Properly arranged the ground for paving slabs depends on its service life. In compliance with all requirements for your Foundation, it will last a very long time.

For tracks at their summer cottage and recreation areas sufficient to be laying on a sandy pillow. Blow-dry mix is required for Parking lots and driveways.

Technology of paving on a concrete base ↑

Laying paving on a concrete Foundation is required at very high loads, which is unlikely in the case of garden paths and Seating areas.

We already talked about the fact that the gravel cushion can be shed with cement mortar surface leveling and concrete base. If the base for some reason, it is necessary to reinforce, in the trench over the gravel pillow set simple wooden shuttering and concrete will be poured up to a thickness of 10 cm with a reinforcement grid with cells 10×10 cm From cracking protects the concrete Foundation to installing the wooden slats across the trench. The rods are set in increments of 2.5-3.0 meters. They will create in concrete expansion joints. The rods are set with the same gradient, and detailed design. Preferably before installation, lubricate rails with a bitumen. When we equate the top layer of concrete, the slats will serve as beacons.

For the concrete base using a mixture of M150. The concrete surface should salesnet, why sprinkle it with cement and razravnyat trowel. The concrete base of a closed film and periodically wetted with water.

Paving slabs laid on a Foundation of concrete for ordinary cement-sand mortar. Previously, the tile is expanded to check the figure and clarify possible places for cutting. In the places of cutting of the tile is marked with.

Then the tile is removed, on a concrete base is applied to the solution layer of 2-3 cm, and begins laying. For precision the width of gaps using the plastic spacers. Constantly check the surface level and remember that we need a slope to drain water. After the solution will seize, fill the gaps with gartsovka and sheds water.

You were introduced to ways of laying paving slabs with their hands. In the technology and precision at work laying quite on forces to execute independently.