Well – one of the most popular ways of water extraction, the use of which allows the owners of suburban areas have the dual benefit of getting high-quality water and savings in financial costs. Drill wells, to supply water at any time of the year. But the narrow hole in the ground cannot act as a full source of water supply, only the arrangement of the water wells allows you to make the life-giving water suitable for use and consumption.

The contents

Selection of necessary equipment

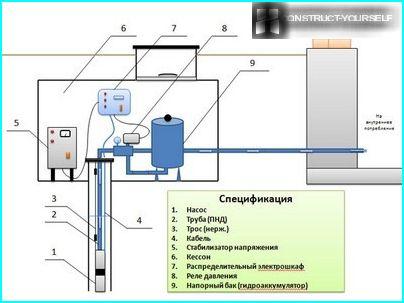

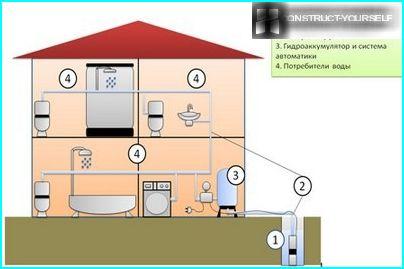

Drilled water wells, you can proceed to its arrangement. To ensure a continuous supply of water is necessary to install special equipment, among which includes: the caisson, pump, pressure tank and the well head for wells.

Scheme of arrangement of water wells in the country are in General the same, differences may be only in the selection and installation of individual elements

Before proceeding to the arrangement of wells, should wisely select design elements in order to protect themselves in subsequent from unnecessary troubles and expenses for repairs of expensive equipment.

The purpose of the caisson

Caisson is one of the main design elements for decorating. Similar in appearance to the barrel watertight container is designed to protect the water in the water system from freezing and mixing with groundwater. In a sealed design you can position the automatic equipment, filters, membrane tank, pressure switch, pressure gauges and other components, thereby freeing the premises from unwanted aggregates and devices. The caisson is typically equipped with a neck with a tight-fitting lid.

The caissons are made of metals resistant to corrosion – stainless steel and aluminium, or of plastic which does not rot and other processes of destruction

Fact! For the arrangement of the wells on their own are most commonly used cylindrical products with a diameter equal to 1 m and height 2 m.

Submersible pump

To your well served in the next few decades, you need to choose wisely submersible pump.

The choice of the product depends on its performance and maximum pressure. To date, the most popular pumps European manufacturers, such as: Grundfos, Water Technics Inc

In the calculation, which defines the parameters of the product, takes into account the diameter and depth of bore, length of water supply pipes, the peak flow of water on all connection points. For stable operation of the supply system necessary to maintain the operating pressure in the range from 1.5 to 3 ATM., which is equal to 30 m water column.

The accumulator

The main function of the accumulator – the maintenance and smooth change of fluid pressure in the intake system. In addition, the tank provides a minimum supply of water and protects against water hammer. Vary the device enclosing volume of water ranging from 10 to 1000 litres.

For a small country house with 3-5 taps is enough to set the tank capacity 50 litres

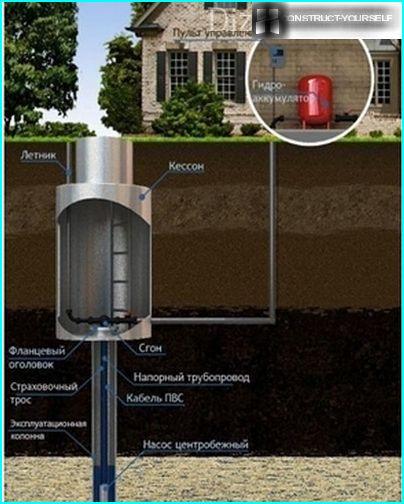

A tip for wells

Installation tip allows to protect the well from contamination by garbage and runoff of meltwater. The design of the seal bore, designed to simplify operation of the well, and particularly suspension pump.

The cap may be made of plastic and cast iron. Plastic products capable of withstanding the load suspended, the weight of which does not exceed 200 kg, and cast iron – 500 kg

The main stages in the completion of wells

The owners of the households that do not have sufficient time, knowledge and skills to understand the schemes of communication, you can always entrust this important work to the experts. Especially skilled do it yourself. But even if you someone will carry out all the work, you will need to check it out. Thus, the organization of independent water supply takes place in several stages.

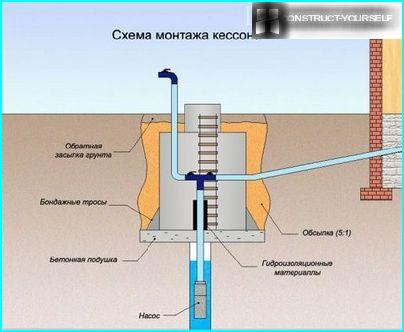

The installation of the caisson

For installation of the caisson it is necessary to prepare a hole you want to dig around the well to a depth of 1.8-2 meters. The dimensions of pits are determined by the dimensions of the container, average width is 1.5 meters. The result should be a pit in the middle which sticks out casing.

If the pit filled with groundwater, it is necessary to create additional recess in order to timely implement their pumping.

In the bottom of the caisson to cut a hole equal to the diameter of the insulating casing. Prepared the caisson can be lowered into the pit, placing in the center of the wellbore. Thereafter, the well casing can be cut and welded to the bottom of the caisson by welding. To the assembled construction is necessary to attach the tube for the withdrawal of water and an electric pump cable. The caisson is filled with a layer of soil above the surface needs to remain a cap, serving the entrance to the building.

Caissons are mounted below the level of soil freezing and additionally equipped with: ladders, storage tank, pumps, compressors and other operating lifting devices

Installation of submersible pump

Despite the fact that the process of pump installation is fairly simple, for its installation it is necessary to consider some nuances:

- before installing the pump, thoroughly clean the bore, pumping water until until the water ceases to give a precipitate in the form of sand and other particles;

- the pump in the well is placed so that it did not reach 1 meter to the bottom of the source, and it was completely submerged in water;

- in parallel with the installation of the pump install a plastic pipe (the water is up), and cable (for control of pump motor);

- protective and regulating device and a check valve are mounted after the pre pump installation;

- after installation, adjust the pressure in the tank is necessary, so it should be 0.9 of the pressure at switch on;

- the rope with which the pump is attached to the cover wedge shall be manufactured of stainless steel or have a waterproof cover.

After the installation of the pump, you can set the cap, which seals and protects the wellhead.

The installation of the accumulator

To ensure an uninterrupted supply of water is not possible without the installation of the accumulator.

The hydraulic accumulator can be installed in the caisson and substructure

The principle is quite simple – after the pump empty the tank is filled with water. When you open the tap in the house, water it receives from the accumulator and not directly from the well. For the consumption of the water pump is automatically switched on again and pumping water into the tank.

The installation capacity in the engineering system required to produce, leaving easy access for repair or replacement in the future. In the place of installation of the tank, facing the water, there must be a check valve. Before and after placement of tank need to install a drain cock to drain water. The fixing of the accumulator with the use of rubber will reduce the level of vibration.

Also, answers to most common questions on the arrangement of wells can be found in video lectures: