Polymers, as the know-how of the human mind, gradually replacing with landscape design, natural materials, mimicking their appearance, but winning at features and price. And if to plastic gnomes and pools people have used, that plastic tile for tracks used less than pavers or stone. It is actively implemented in the city squares and streets, and the ordinary cottager while cautious or just not familiar with the technology of laying this material. Let’s try to understand the nuances of the construction of garden paths from different types of plastic tiles.

The contents

Than plastic tile different from the polymer?

The Internet is often a whole block, which is polymers are called plastic. Therefore, in this category you can see the material of 100% plastic and polymer blends with natural ingredients like quartz, crushed wood, etc. But the durability and beauty of coatings are completely different.

Clean plastic looks simple, it has low resistance to frost, after several winters starts to burst, to crumble, gradually fade, etc. Such tiles are used as a temporary coating, not to carry dirt into the house or in areas near farm structures where aesthetics are not so important.

Plastic tile comes in bright colors and unusual design, but loses the spectacular view and begins to crack in the joints

The mixture of polymers and silica sand has a high strength due to the addition of quartz, which the frost will hold, and the active movement of people and vehicles. But the appearance of this tile remains artificial, not imitating any other material. Her solid relief surface is perfect for paths, near pools, ponds, where natural coatings face a high humidity. But as the main, leading from the gate to the main entrance to the house, the polymer-sand tile choose not all. If the house is covered with artificial material, for example, the siding, the coating will look harmonious. But on the background of wooden or stone structures a path to lose in aesthetics.

For perfect smoothness of the surface can immediately recognize that a coating of artificial ingredients, but the path to change the weather will not slip

The most luxurious kind has decking – decking boards, in which wood flour is mixed with polymer additives. It highly resembles strips of wood, i.e. wooden floor, so the view of the track turns out solid and respectable. Call the decking plastic tiles would be a stretch, since different manufacturers add the shredded wood and polymers in different percentage. These components can be mixed in a ratio of 50:50, but very close in texture to the natural wood is a coating, where the polymer is only 20%. Accordingly, the requirements for the installation are changing. The more natural the composition, so it is more resistant to moisture and therefore requires proper reason.

Texture decking is very much like natural flooring, but fits much easier due to the large size of the tiles

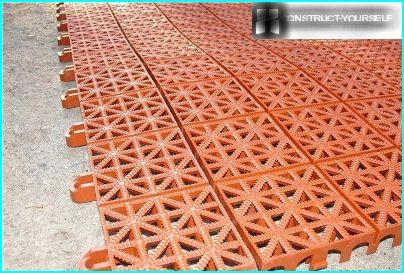

Stacking modular tiles: Assembly type constructor

Modular plastic floor tile for garden paths often has a perforated surface below through it freely away moisture and dust. These tiles are joined together by means of locks located on the sides of the ribs. Their Assembly is like a game with the children’s designer, so the track will be able to collect even a child.

Often, for durable fixing of the modules in a plastic tile is provided for additional fastening, which makes the coating more resistant to stress

Stack lattice tiles on any flat surface where the elevation changes do not exceed half an inch. They can be laid straight and right angle corners. On the lawn lay out the tiles without any preliminary work, as the surface is already leveled up to the moment of seeding the site with grass.

Lay on the lawn plastic tiles can be in just a half hour, but to preserve it for a long time, before the winter, the track should be dismantled and stowed in the outhouse

Laying on the ground, for example, when creating paths between the beds, it is recommended to first build the base non-woven material that is not penetrated the weeds, and top – attach tile.

If the area is an old concrete path with cracks and potholes, first it should be slightly repaired, smeared all visible defects in the adhesive or cement mortar, and put the unit coating. Modular plastic tiles is not designed for strong static load, so for her I go only on foot.

Polymer-sand tile: laying on the type of pavers

Tiles of polymers with quartz aggregates has emerged as an alternative pavement that is able to nourish moisture and this gradually disintegrate. Plastic cover this problem does not exist. And yet, technology of stacking tiles of polymer concrete are identical. It is necessary to create the same trough, the sand-gravel cushion, set curbs and so on can be placed on a concrete base, gravel or ordinary sand-cement mixture, depending on the load, which must withstand the treadmill. All the nuances of styling we have already written in articles «Technology laying paving slabs» and «The rules of laying paving slabs on a concrete base», so here is the detailed process will not describe.

Just to say that the quality of laying the Foundation in the future will affect whether it will maintain through the winter your walkway perfectly flat surface. At the seams moisture will still seep between the tile and substrate, and if it is bad to condense the sand, it will give the sediment, thereby pulling down all the upper layers. Concrete, on the contrary, does not pass water, if you do not create drainage holes, and block it under the tile. And in winter, expanding ice will put your path. The tile itself will not suffer, because she is not afraid of no water, no frost, but the track will have to shift.

In Europe figured out how to save plastic track from heaving quite a simple way. Instead of creating the trough and «pillow», they’re making fertile soil for no more than a bayonet of a shovel, level the surface with hard-Packed sand on top of it and lay extruded polystyrene – insulation that is completely impervious to moisture and therefore does not freeze in the winter, keeping the structure warm. Next, pour the sand-cement mixture, and laid tile. Joints filled with sand. This technology is particularly popular in Finland, where the swampy soil over the winter lifts even the concrete slab on the ground, not to mention lightweight plastic.

Some owners complain that in the summer of polymer-sand tile emits a specific odor, but if it is regular to shed in the heat, then this is no problem

Decking: decent appearance + easy to install

Decking is also called decking, liquid wood, or the garden parquet, emphasizing his street mission. It consists of thin strips resembling plank flooring, which are bonded 4-5 pieces in one tile. Between the bars there is a gap for the passage of water. The width of the gaps varies from 0.1 to 0.8 cm, and when laying the garden path focus on soil moisture. The higher it is, the more clearance you need to choose a decking.

There is a seamless option of decking that looks like elongated rectangles. But to track this type of decking to use is not necessary.

To provide good moisture drainage and ventilation of the material, manufacturers have created a square decking of two components: external part, resembling a tree, and the substrate. The substrate is a plastic grid with fasteners at the perimeter for jointing of tiles between them.

Thanks to a plastic base, garden flooring retains ventilating properties, removes moisture and thereby extends service life to 50 years

Laying decking is needed on a smooth, hard surface where the coating will not «sinking» and keep the air gap through the substrate. Therefore, as the basis do not use sand. Lattice substrate is simply pressed into him and cease to perform their functions.

The best materials for the Foundation:

- concrete;

- Board;

- a shallow layer of crushed stone or gravel;

- ceramic tile.

Of these options, the Board and tile are used more often on the terraces, and walkways poured concrete (if it will move the transport) or were currently covered with gravel (enough layer up to 5 cm).

To make the edge of the track can be either a plinth or lateral laid-on plates.

As you can see, polymers are able to acquire completely different characteristics, thanks to the introduction of the other components. Therefore, before purchasing plastic tile specify its composition, in order to know how many years it will hold your track.