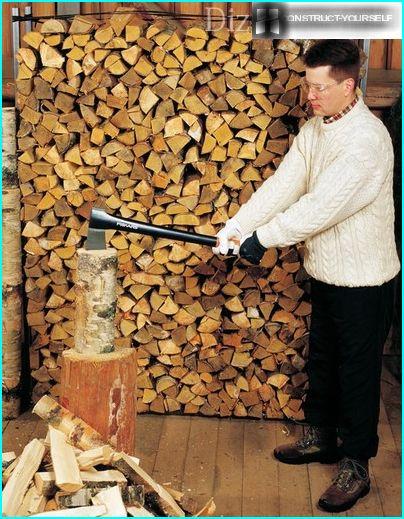

Axe think rightly «king» carpenter tool. A real carpenter related professionally to their craft, knows how to make an axe ideal for a particular operation. The master, as a rule, a few axes, always ready to work. However, this tool need not only carpenters, but for ordinary people living outside the city in private homes, as well as citizens leaving for the summer or weekend cottages. Chop wood to heat the oven in the house or in the bath, it is necessary to master each. To make the process faster and didn’t cause trouble in the form of a flying axe, blunt or broken blade of the ax, should be able to properly prepare the tool to work and maintain it «combat readiness» during the entire period of operation. Form of stick may be different. Important correctly to plant the axe, riving, and then sharpen the blade to the desired angle.

The contents

Buying axe or how to choose the stabbing part?

When buying an ax, or rather pricking the parts, should pay attention to the quality of the metal taken for the manufacture of tools. Look for the axe mark GOST, which confirms the compliance of the metal to the state standards and requirements. Beware, if instead of this sign will stand THE OST or MRTU. In this case, the manufacturer may make changes in technology. The axes of Soviet times, characterized by high quality metal, can be purchased at a flea market.

The quality of the metal can be checked and empirically, taking two of the ax and hit the blade of one of them on the blade of another. A less quality product will remain the notches after the attacks. Also the quality of the metal is checked by the characteristic sound, which appears when tapping the ax. The tool must be in limbo.

You should also focus on the following points:

- the well-drawn the blade should not be bent;

- manuaalisesti form eyelets;

- the alignment lugs and axe blades;

- a small thickness of the butt and its ends perpendicular to the blade.

Don’t worry, if you can not find the ax that meets all these requirements. Because deviations can be eliminated by sharpening burrs, boring eyes and give the butt a symmetrical shape.

The choice of procurement and manufacturing of the ax

The length of the stick depends on the growth and strength of the master. Not the last role is played by the quality of the wood. Lightweight axes, having a weight of about 800-1000 grams, have a handle length of 40 to 60 cm for the heavy tool (1000-1400 g) the length of the stick varies from 55 to 65 cm.

The length of the stick depends on the force of the blow. The longer the handle of the axe, the easier it is to chop wooden chocks. The strength and growth of the person also matters

Not every wood species suitable for making the handle of an axe. For this purpose, a true master comes to the entire forest before finding a suitable tree. Most often the template for the stick made from the root of the birch, and the best of the growths on its trunk, gnarled and very very dense wood. Instead of birch, you can use maple, oak, acacia, ash and other deciduous trees of firm breeds. The workpiece must be well dried in natural conditions, and that will take a lot of time.

On the prepared workpiece contour for the selected pattern the contours of the future of the ax. At the end of the handle of the axe shall be provided with a thickening intended for «braking» hand in case of slipping out of the tool. Then the excess wood outside the contour are removed with a knife, an axe with a perfectly sharpened blade, chisel or a jigsaw that much faster. After completing the fitting head of an axe on toporishche with mallets, and, making a tight fit of these parts, you can continue finishing tool handles. For sanding use glass, but for polishing fine – grained sandpaper.

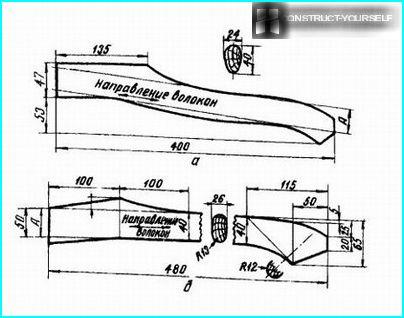

Above shows the drawing of the ax (a) that meets the requirements of GOST 1400-73 and bottom handle camping axe (b) a zone of undisturbed fibers constituting 40 mm

Important! If the ax easily into the eye, it means that the master erred in calculations and incorrectly drawn the pattern. In this case, even drive a wedge does not correct the situation, providing short tight fit of an axe on toporishche.

How to plant an axe handle?

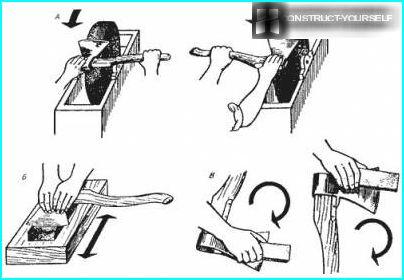

The following is the algorithm of operations, showing how to plant an axe on a carved and polished ax. This is one of the possible ways:

- Adjust the upper part of the stick under the eye of the axe. The extra wood sostragivaja knife. File use is not worth it, as it «razmeram» tree.

- On the axe handle placed in a horizontal position on the table, put on top of the ax, and with a pencil put the handle label, to which he will sit down. Divide the segment in half and place a second mark.

- Clamp the handle in a vertical position in a vise so that the wide end was located at the top. Take a hacksaw and make a propyl to a second label under the wedge.

- Buy shop metal wedge or vystrugat wooden counterpart, whose thickness should be from 5 to 10 mm. the length of the wedge, made for the axe with his own hands, must be equal to the depth of cut and width – the size of the eye of the ax.

- Put it on the table Board and put it on the axe, placing it upside down. Put the axe on toporishche and start tapping them on the Board. Then flip and tap the Board with the handle of the ax, the process of fixing continues. Turning and tapping need to be done several times. In the end, the axe handle enters the eye.

- Next, put the axe handle vertically and insert propyl-planed wedge, hammer it with a mallet to half or almost to the end. A hacksaw will cut off all that will remain stuck on top.

- Apply oil (engine, Flaxseed, sunflower, etc.) in ax, let any excess drip off and leave to dry. Wipe the axe and the handle with a rag.

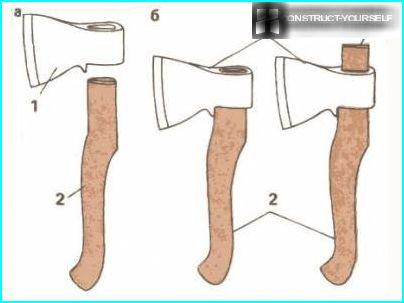

After fitting the axe to the axe handle, shown in figure (a) produce his tip (b) and wedging the handle (in): 1 – ax 2 — ax, 3 — wedge

How and at what angle to sharpen the blade of an axe?

The tool is not trouble, it is necessary to properly sharpen the blade of an axe. In accordance with the requirements of GOST, the angle of sharpening an axe building must be 20-30°. Tool for carpentry is sharpened at a slightly greater angle of 35°. Recommended angles necessary to maintain, as a thinner blade will get caught up in the wood. Their pulling out will have to exert extra effort. The knot on the thin blade can easily bend. Sharpened angle 35° blade, podlasia detachable from the main logs, wood chips, not bogged down in the wood.

First performed «draft» primary sharpening the ax, during which it is possible to eliminate the rotating grinding everything around Shcherbinka, minor injuries and major potholes. If this is the formation of a new sharp cutting edge of an axe. Then roughly sharpened blade is subjected to «fine» sharpening. Grinding is carried out along the entire length of the blade on both sides a fine-grained whetstone, which removes all burrs.

Three ways of sharpening the blade of an axe: a) grindstone; b) the block is moistened with water; C) edit a whetstone soaked in motor oil

Important! The Shine of the blade of the axe with the lack of cutting edge Burr says that the sharpening process was successful.

This video shows you how to sharpen an axe using a grinding machine. This is one of the alternative ways.

How to store the axe?

It is recommended for the axe blade to put a cover made of thick leather, birch bark or other material. Do not leave the ax stuck in a log. A true master cares for his instrument, because the axe is «continuation» his hands.

Once chopped wood homemade axe, you will not be able to work the store tools. If you doubt their abilities, then use the services of artists who know how to make a comfortable handle for an axe from selected and dried workpiece.