In the Arsenal of the home worker will always be functional and easy to use disk saw. But there are times when you want to cut the part and perform a small amount of work and to expand and connect the Assembly no time or desire. In these cases, I like that it is a manual hacksaw. But how to choose the hacksaw on wood, so it was easy to use and easy «gnaw» any wood species, let us consider in more detail.

The contents

Technical characteristics of the instrument

The saw is considered to be the progenitor of a large family of hand tools. Since the establishment of the first iron type of weapon saw a lot of changes, having to acquire numerous «sisters», able to perform dozens of works.

In the household it is impossible to do without «toothy assistants»: they are indispensable when trimming the garden, small carpentry and joinery

Hand saw for wood differ by many parameters: size of leaf, steel grade, shape of teeth, the lever design. Let us discuss each option in more detail.

How must the saw blade?

The main part of the tool is a saw blade. The first thing you should pay attention when selecting a product – the length of the fabric. This parameter depends largely on its application. At the same time, the longer the fabric, so it is more springy, which also complicates the process especially when working with hard woods such as ash, maple or oak.

Long stroke allows the cutting to make less effort, as in one move the cut runs a large number of teeth

For the cutting of small elements such as floor, bars, or narrow strips can be dispensed with a hacksaw with a length of fabric in 25-30 cm Planning to use the tool when performing more major construction work, choose the product with a cloth 45-50 cm.

In determining the length of the saw blade, follow the rule that the length of the saw greater than the diameter of the elements being processed 2 times. Failure to follow this recommendation, you will only complicate your work. The short teeth of the hacksaw will stick inside the wood, and to promote the release tool of sawdust each have to exert a lot of effort. Uncomfortable work will cause premature fatigue.

Traditionally, the width of the product varies in the range of 10-20 see Models with narrower blade for technical reasons are not allowed, since it goes down at the slightest bend. But remember that too wide of a cloth awkward for handheld work.

Equally important is the material and the manufacture of cloth, which is often alloy steel, and quenching degree

For the hacksaw used tool alloy steel with a high content of silicon and carbon brands:

- 65G, 60 C2A;

- HF 8, HF 9, 9 KHS;

- U7, U7A, U8, U8A, U8G, U8GA, U9A, U10

Hardening of metal is carried out by exposure to an alternating magnetic field, in which appears an electric current of high frequency. Spreading over a surface, it heats the surface layer of metal, which after cooling is tempered.

The standard parameter is the hardness of the metal 45 HRC, but still preferable to choose products, the hardness of the fabric which is 55 to 60 HRC. A hacksaw blade with high hardness will have sufficient flexibility, but the high stability of the teeth. At external examination of such instruments to determine darkish shade of sharpened teeth.

The parameters of the teeth on the blade

Determining a measure of performance of the work tool and precision cutting of wood is the size of the teeth.

The teeth of a handsaw for tree serves a dual function: cut the wood and parallel to this, the sawdust is removed

Cutting precision is determined by the index «TPI»- number of teeth per inch.

Between these technical parameters, there is an inverse relationship:

- leaf with large teeth set the high speed works, but spil this gives a rough and messy;

- hacksaw with fine teeth guarantee a clean and precise cut, but at a relatively low speed.

In determining the required size of the teeth should be guided by the appearance of the treated material. For example, work with DSP, which requires a high precision of the cut, choose a tool with high «TPI» 7-9, and the log cutting and work in the garden, where cleanliness of cut is not as important – «TPI» 3-6.

When choosing the best option type follow the rule that the minimum thickness of the wood should be in any case more step three teeth

If we compare with a hot and a normal tooth, the difference is that in the first embodiment, assuming domestic use of the product long blunts. But the saw with tempered tooth re-sharpening anymore. When it becomes bad cut, it will just throw.

A normal tooth is amenable to sharpening. Periodically it may be performed using a special file marked accident (for Potocki drinking). To sharpen the canvas, it is enough to perform several movements on each tooth.

Depending on the type of teeth there are three types of hand hacksaw:

- For longitudinal pilenija. The product is equipped with teeth in the form of oblique-angled triangle and externally similar to the hooks. The tool allows you to perform the sawing of the wood along the grain. These saws are sharpened with both sides of the tooth, thereby capable of cutting as when passing forwards and back.

- For cross-section pilenija. Teeth tools are made in the shape of isosceles triangles. This design makes it easy to cut material during the cutting edge forward and backwards. But this type of tooth is only suitable for working with dry pieces, but not fresh wood.

- For mixed pilenija. The products have combined the composition, in which the triangle edges combined with a slightly elongated semi-circular notches. This solution allows the movement of the hand forward semi-circular teeth to perform the cutting guide, and when you return the triangle to expand the channel, bringing him chips and sawdust.

Some types of modern tools are equipped with teeth, which are made in the form of a trapezoid. This solution allows to make the fabric more durable and wear resistant.

But it is worth considering that to sharpen this blade is highly problematic because of the trapezoidal teeth are difficult to give the desired shape. This greatly reduces the life of the product, after which you have to change the blade or buy new tools.

For cutting fresh branches convenient to apply fabric, equipped with a triangular head, processed in parallel by grinding, in which each element sharpened on one side only and staggered

Often in the market you can meet the upgraded look of the hacksaw.

Upgraded hacksaw easily distinguished on the canvas of groups of teeth between which are spaces

Hand saw re-type efficient for cutting wet wood. The wet chips through the gaps between the teeth in the cutting process is easily out cut, impeding the movement of the tool.

Types of manual saws for tree

Option #1 — narrow

A small narrow saw, is a structure which consists of a straight flat blade and a handle. It performed fine work and cross cuts, cut out the curved details.

This type of tool is designed for cutting wood workpieces whose thickness does not exceed 8-10 cm, podpira small branches and small jobs in the garden

In the manufacture of narrow models set fabric with double-sided triangular teeth, or with parallel shank. The disadvantage of this tool is that when you push in the process, the fabric is able to deviate from the specified direction.

Option #2 — basic

A standard hand saw may be equipped with any type of teeth and are often equipped with replaceable cloths of various type and design.

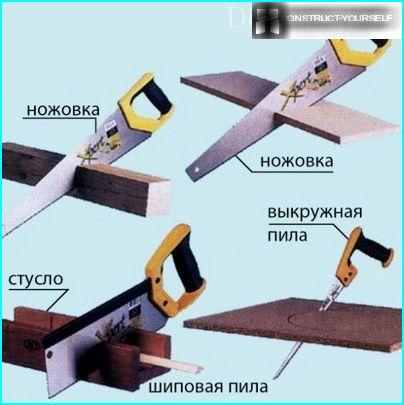

To be able to cut off the workpiece at a certain angle using a standard hand saw have to buy a special mitre

But despite the universality of their application, saw that TIA is not desirable to use in the manufacture of furniture.

Option #3 — butt

Both narrow and conventional saws by increasing the rigidity of the processed material prone to flexing. In these cases effectively use canvases come with a butt, which acts as a kind of stiffener.

Manual cutter, equipped with back of the blade are designed to create shallow cuts in the wood surface of any thickness

The presence of the back of the blade, allowing the saw to make the cut depth is greater than the width of the fabric, as it prevents the passage of blades on a tree.

Option #4 — segmental

Saw bow-shaped type is a more bulky device acting analog of the jigsaw.

The main purpose of drinking this type – the creation of a precise cut when working with surfaces arranged at any angle

Thanks to the thoroughness of the design and the threaded connections of the arms of the saw bow-shaped type can easily overcome bitches, performing a cut along the radii and curved patterns.

Depending on the purpose and constructive solutions saw can be:

- razmernye – for longitudinal cutting;

- cross – cutting blanks transversely to the wood fibers;

- vykruzhnye – for cutting holes, performance curves and curved sawing;

- tongue and groove – for cutting the connecting tenons, and sawing the workpiece of simple geometric shapes.

Only hacksaw bow-shaped type, you can cut the material up and down, Napili workpiece with complex lines and doing the work alone without the involvement of the assistant.

Recommendations for tool selection

Procedure, how to choose a hacksaw on wood, is pretty simple:

- Determine the purpose for which will be used tool. For joinery choose products with fine teeth for high-precision cutting for carpentry – leaf with large teeth.

- The frequency of application. If hand saw is used only for one-time work, choose a tool with hardened teeth. Resource exploitation of this type of product is quite large. In addition, you do not have in the process of exploitation to worry about grinding and separation of the teeth.

- The uniformity of the fabric. Viewing tool, try to gently bend the canvas by setting the angle in 30-45°, and then release it. Re-inspect cloth: the slightest deviation at the point of bend even in the range of 2 mm indicate low quality metal.

- The cost of the product. As with other tools, keep in mind that quality models from leading brands are always much more expensive consumer goods. This overpayment acts as a kind of guarantee of wear resistance and durability of the saw. But for one-time work makes no sense to spend money on an expensive tool.

A regular arm made of plastic. Prefabricated plastic handle made of two halves, do not possess sufficient rigidity. Much easier to work with the tool having-molded handle, which is equipped with rubberized backing for the fingers. The presence of a rubber insert allows you to make tighter the grip, preventing the formation of calluses on the palm of your hand.

Pay attention to the design of the handle: it is desirable to have an ergonomic shape that allows to properly transmit force to the canvas

In sale there are products with standard and reversible handles. The second option is convenient because it allows, if necessary, to replace worn-out canvas new.

Keep in mind that not all hand saws go on sale sharpened. And from this, it would seem, trifles depends largely on how soon you will be able to get to work.

Firms that manufacture saws, on the market there are many. Judging by the reviews, is currently well established: hacksaw «Bison» domestic production Gross Piranha joint German-Chinese cooperation, Irwin Xpert made in the USA. They are known for decent quality at a low price, which varies in the range of 10-20 at.e.

Finally, we offer you to watch a video with tips on choosing: