From the rich assortment of building materials suitable for the manufacture and installation of gates, individual developers often choose corrugated sheet. Prefer this building material is given for a number of reasons, including strength, durability, decorativeness, and, of course, affordable price. Corrugated sheet is manufactured in the factory conditions of a steel sheet by cold-kata. On both sides with sheets of metal profile is applied a protective layer of galvanizing protects the metal from corrosion and premature destruction. For extra protection and enhance the decorative qualities of the corrugated sheet are covered with a polymer layer, the colors of which may be very different. To make the gate of corrugated Board with your hands, you just have to find a couple days and a couple of hands. After all, to build together is always more fun and faster. However, in addition to the hands you need to be a welding machine and a minimal set of tool.

The contents

What are the design and the good working?

Why corrugated? Because it provides:

- Durability. Made gate will be able to stand a quarter of a century, it does not require much maintenance, and repair.

- Light weight used materials, that facilitates the installation and delivery of all necessary on the subject.

- The choice of textures and colors, based on the preferences of the owner of a household. Gates combined with fence, roof and other finishing elements of the buildings standing on the site, will decorate any area.

- The savings on the paint, because the gate of corrugated Board do not fade under the action of sunlight and do not fade under influence of precipitation. When purchasing, pay attention to the manufacturer, because the fakes may not possess such qualities.

In addition to all the other of course is the low price in comparison with other materials and taking into account their characteristics.

So, there are several types of gate structures, among which the greatest distribution was received with two options: swing and sliding.

Sliding gates of metal profile construct with your own hands is difficult, therefore, to perform this task, it is better to invite professional builders

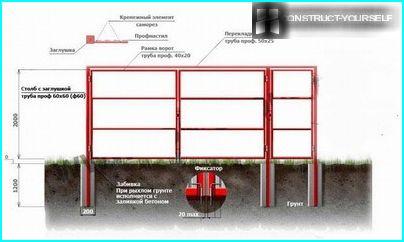

Self-collect easier for hinged doors, composed of two identical halves, each of which opens in its side. Of course, you can make one large leaf turning in one of the sides. However, this option drops a big load on the loop, which is hung all this «mahina». Therefore, most developers prefer the classic folding design of the swing gate. For journey on the territory of passenger car and small truck is sucient to construct a gate width of 4 meters. Height welded frame can be 2-2,5 meters.

Important! If you have free space the gate can be installed next to the gate. Otherwise, the gate (door) slams directly into one of the folds.

Preparation of pits and setting of gate posts

Supporting pillars for the gates can be constructed from the following materials:

- wooden beams, the section of which is 150 by 150 mm;

- whole round logs with a diameter of at least 20 cm;

- channel beam, the thickness of which is equal to 14-16 mm;

- shaped tube (80×100 mm), the thickness of which is 7 mm.

After marking the site starting to dig holes for the installation of the gate posts, using a regular shovel or garden drill

Having defined the material for the pillars, start digging pits, the depth of which is equal to one-third of the height of the aerial part of the portal posts. It should be noted that the fabric of gate leaves usually do half a meter shorter than the pillars. This stock allows you to provide a lift of the lower edge of the gate from the ground surface at 20-30 cm, and leave a couple of tens of centimeters from the top for welding decorative elements that adorn the entire design.

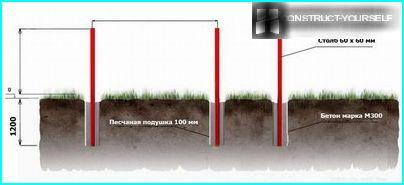

The resistance of the gate depends on the strength of the pillars, so to manufacture them choose steel. For setting the profile pipe or channel beam drilled a hole 1.2 meters deep and a diameter of about 20-50 cm Prepared by metal poles are lowered into the pit, set at level, upright position and filled with cement mortar. Preparation of the posts is to sweep the surface from rust, followed by primer and paint, and to install top caps to prevent ingress of snow and rainwater.

Installation of poles for attachment of gate leaves is in the upright position followed by fixing them with cement mortar

Article topic: Setting poles for the fence: ways of assembling different designs

The choice of core sheet for covering woodwork

Profile sheets are divided into three groups, which differ from each other in thickness, height of fins, degree of strength. Each group has its own marking:

- «With» — wall trapezoidal sheet, made from galvanized steel sheet of small thickness, having a small fin height. Lightweight and durable material, which is usually opt for the self-Assembly of winch.

- «NS» — sheet metal, different from the material of previous brand larger wave height and greater thickness. This affects their weight and level of strength.

- «N» – «bearing» sheet metal used in the construction of steel hangars and roofing a large area. Heavy profile sheets of this brand have a high level of durability. To use them for covering woodwork expensive and impractical.

It is best to build gates made of profiled sheet brand C8 and C10 (the numbers denote the wave height in millimeters). The thickness profile of the sheet varies between 0.4 and 0.8 mm. Fold from this material weigh from 25 to 40 kg, so to cope with their mounting under the force of two workers. Lifting equipment draw will have, which will save on the cost of the gate.

Important! The cutting sheet to fit the size better to order at the factory (subject to availability). Special equipment available to manufacturing, could ensure the cutting precision, accuracy of cut and minimize potential damage.

Manufacturer of frame frame

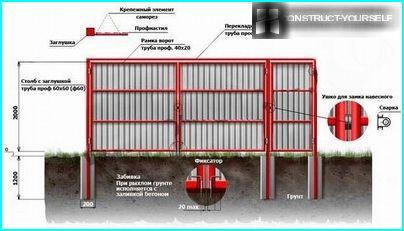

The frame for the manufacture of the gate leaf can be made of wooden boards or of the profiled tube of rectangular cross section (40х20 mm), the walls of which have a thickness equal to 2 mm. If the metal poles are supplied, then the frame should be made of the same material. Going gate frame on flat ground, enclosing at least one sash. Corners turned out straight, use precise measuring instruments (triangles). You can also use a homemade device made of rope, folding into a rectangular triangle with sides 3,4 and 5 in. From the profile frame is welded as a rectangle using the welding inverter, the corners are further reinforced with steel corners, giving the design greater rigidity. The long side of the frame is divided into three parts and is welded to the marked locations parallel to the lintels, reinforcing connections steel corners. In these places it is welded loop gate.

The scheme of making frames for gates made of profiled tubes having a rectangular or square cross-section. The method of fixation of the closed gates

Important! If you intend to make the gate in a gate, the frame is a little different. In one of the valves by longitudinal and transverse bulkheads welded to a rectangular frame, frame gate 80 to 180 cm the location of the loops shift to the lower and upper edge of the gate.

The covering of the gate frame with sheets of corrugated sheet

To the casing frame profile sheet proceed immediately to the place of Assembly of the frame. For fixing profiled sheet using special fasteners – screws hex head painted in the same color as the material. The hinged gates leaves with a wavy surface bolted by bolts or welded welding. Length of loops for the gate must be at least one meter, and their thickness at least 3 mm. When mounting the assembled panels you can use a small winch, which cling to the beam, laid on top of the gate pillars. On the ground stack bars, which set the shutter door to fix a weld on the pole ends of the loops. It is possible for the insurance to fix the hinges with the bolts. Bars removed from under the gate valves and check how easy they are opened and closed.

Mount profiled sheet to the frame of the gate using special screws that have hex heads, painted in the color of the main canvas

As you can see, nothing complicated in the construction of the gates made of profiled sheet no. It is only necessary to draw a drawing, calculate and purchase all the necessary materials to carry out installation work. A few days of work and a beautiful gate made of metal profile will be the hallmark of your home.