The contents

Plastic water pipe long ago came into our life. A fixture in the repair of Soviet housing, along with plastic Windows, was the water supply system of polypropylene pipes.

The advantages of polypropylene water pipe before the steel pipes are obvious:

- Cheapness and a wide range of materials;

- The simplicity of the work on partitioning and build the most intricate and complex routing of pipes;

- Environmental friendliness, material resistance to corrosion and salt deposits on the walls of polypropylene communications.

Those who are faced with a tedious and time-consuming plumbing installation of metallic pipe, can appreciate the simple connection technique of plastic using a special soldering iron for polypropylene pipes.

If it’s time to repair the apartment, a problem with the replacement of plastic plumbing utilities, depending on the availability of desire, money and free time to solve:

- The hiring of the master and friend who has experience with the device for soldering polypropylene pipes that help to collect using the soldering iron is marked and cut into single unit pieces of plastic pipes;

- Transfer to the mercy of the repair «turnkey» brigade repairmen without any desire to deal with the intricacies of assembling and soldering plastic assemblies;

- The performance of all work with their hands.

Ease of Assembly soldering plastic so captivating that it is difficult to resist the temptation to solve the problem of water supply not otherwise, how to choose and buy a soldering iron for polypropylene pipes.

The amount of money spent on the purchase of the instrument will be less than the cost of the services of the wizard, but provided that you really know how to choose a soldering iron for polypropylene pipes. In fact, soldering iron for polypropylene parts and fittings is a heating element with thermo-mechanical or electric heating controls and display. On the heater are mounted two nozzles, allowing to heat the soldering iron the outer surface of pipe and inner surface of the fitting. Heat lasts an average of about 5C, details connect with slight pressure with your hands to grasp and the formation of strong connections over 2-3s. In case of overheating or krivobok connection parts may contact with part of the melted plastic inside the pipe, as a result, reduced bore.

For innovators and tinkerers their hands you soldering iron for polypropylene pipes raise their hands. From perfect soldering iron and the quality is polypropylene pipes, depends on the strength and durability of the soldering.

Than a good soldering iron, assembled with his own hands ^ a

The principle of operation of a soldering iron is simple and uses the principle of sticking heated to the softening temperature of the soldered surface of the polypropylene parts. Not always there is a need to re-ReWire or resolder half of wiring of water supply networks in the house. Sometimes you need to work with a soldering iron for two or three connections. In this case, can help out home-made, hand made mini soldering iron for polypropylene pipes improvised from heater.

For a person with experience with electrical wiring and plumbing skills to produce small Amateur version of the soldering iron for polypropylene pipes – a matter of two hours.

As a rule, water pipes laid in channels and hidden from the eyes of a stranger screens and decor, so do not worry about the beauty and aesthetic form. What is more important – incorrect adjustment of the temperature and overheating of the material of the pipe or fitting, under even a little stress will lead to marriage. In soldering the first and main issue is the quality of the connection details.

If you are working on a homemade soldering iron can be slightly not make it to world standards of appearance – not a problem for Amateur cases permitted.

To build a homemade soldering polypropylene pipes will need:

- Heating element – the sole ordinary electric iron, preferably in the form of a closed block of aluminum with a thermostat and an electric cord with plug;

- a nozzle on a soldering iron for polypropylene pipes and fittings of the required size for your pipes;

- Nickel-plated bolt-nut M8 for mounting the nozzles on the heater;

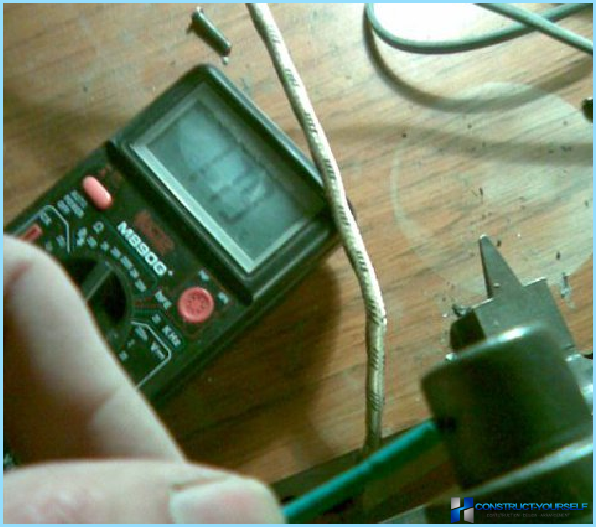

- digital multimeter with an external thermometer on the basis of the thermocouple;

- clamp or other attachment, allowing secure soldering on a utility surface.

In addition to temperature, important speed or power of heating the surface of the parts. If you heat polypropylene fitting or pipe long enough – parts exposed to the temperature being out of shape and dimensions.

Therefore, to quickly melt the surface with a diameter of 15-30 mm, the necessary capacity of 700 – 900 W, which corresponds approximately to the maximum power of the heater iron.

Collect home-made for propylene couplings:

- At a distance of 30-40 m from the bow of the aluminum sole drill a through hole with a diameter of 8 mm and with a screw and nut connecting the nozzle to the pipe and the fitting with the base of the heater;

- Set the iron stick on the soles of the heater so that it does not limit access to the pinned attachments;

- Connect the wiring to the contacts of the heater of the iron;

- Included in the network and with the help of multimeter, digital thermometer and regulator on iron exhibit temperature 265onWith.

Use a clamp for fixing a homemade soldering polypropylene pipes, which will allow to solder the parts on their own, without an assistant, the handle can also be done under the greatest convenience and minimal risk of a burn.

What soldering iron for polypropylene pipes better ↑

It was always considered that the best tool is the professional version designed for long term use and having high performance soldering polypropylene pipes. Professional soldering tool for plastic pipe includes:

- Application to nozzles materials resistant to prolonged heating, high conductivity, not adhering to the heated surface of a polypropylene component; as a rule, use brass or copper heads, Teflon-coated or carbon fiber;

- Lightweight and easy to change attachments on the flange of the heater, the kit is supposed to set the basic dimensions of pipes from 16 to 160mm;

- Metallized surface of the nozzle gives a high heating rate of the polypropylene parts.

- The presence of the stabilizer power of the heater and autoreguljatsii temperature allows to keep the soldering iron in a hot condition indefinitely without the risk of failure of the heating element.

Essential attributes of professional models of soldering irons are easily removable stand and storage case and to carry the device with accessories.

For example, is widely known variant soldering iron for polypropylene pipes dytron or ditron – as you like. He gives high marks for reliability and ease of use, simplicity and robust construction. When soldering parts propylene the second is, we have to put quickly, drop or even throw the linstock on the stand, and it practically does not affect its performance. In the line of DYTRON three models:

- Capacity of 850 VT, the chassis housing repair, is used for polypropylene pipes with a diameter up to 36 mm;

- Capacity 1200 watts – for polypropylene pipes with a diameter up to 160 mm;

- With a heater in the form of a rod, with a capacity of 650 W.

The soldering iron attached key for bit changes, which can be set from 3 to 12, scissors for cutting polypropylene tubes, construction level, gloves and stand. With all the advantages, it is worth noting one negative thing – obviously inflated price of a soldering iron.

But even the experts involved in the soldering of water pipes do not always want to buy a soldering iron for polypropylene pipes in an expensive professional version. Many of the budget models collected from Chinese and Turkish components work perfectly is not worse than branded models.

Take for example a typical workhorse repairer – soldering iron for polypropylene pipes «Union»:

- High-power heater up to 2 kW;

- The set consists of six model bits with a diameter from 20 to 63 mm;

- In addition, the soldering iron is equipped with a hexagon key for changing working tool, a device holder and carrying case.

Power cord length is 130 cm, which is clearly insufficient for the job. But this size is typical for budget models, while professional soldering irons have a full 2.5-3.5 m. «Union» equipped with a dual mode push-button heating controls and the two color indicators – green and red, the latter illuminates of heating automatics.

A soldering iron equipped with everything necessary for successful soldering polypropylene pipes, so it’s hard to say – whether to overpay for the accessories, as in the case of expensive models of soldering irons.