When you look at the beautiful embossed cover of the walls, paths and fences is hard to imagine that all of them are made of the usual material — concrete. But modern coatings, unlike its «ancestor», known for its unattractive dull grey appearance, are of particular aesthetics. Due to its presentable properties decorative concrete is widely used not only in construction but also in landscape design.

The contents

For the first time decorative concrete was used in the early 60-ies of the last century by the Americans during the construction of runways at military airfields. Before them the task was to create a building material, which successfully combines both excellent performance and decorative qualities. Material that consisted of cement, water, filler, paint additives and is fully consistent with these requirements and therefore is widespread in many industries.

Today, decorative concrete can be seen on car parks, roads and sidewalks, metro stations. It is used in restoration of monuments of architecture

Thanks to the efforts of developers today, decorative concrete has a number of advantages, principal among which are:

- Resistance to petroleum products, chemicals, and aggressive compounds;

- The ability to withstand load (2-3 times more than extruded paving tiles);

- Resistance to UV radiation and the ability to withstand up to 300 cycles of freezing;

- The ability to withstand extremes of temperature range from -40°C to +40°C;

- Resistance to abrasion and mechanical stress.

Using extruded concrete to create an exceptionally beautiful and durable coating. Special additives included in the composition of the material, made to prevent delamination and cracking of the surface.

Unlike conventional concrete, the technology of which is reduced to the usual pouring, decorative concrete involves the application on the top layer after the final fill of a certain pattern.

For surface design involves different punches and other special tools. Stencils, molds for sand-blasting and chemical compositions for etching can create complex patterns and fine lines, made with saws with diamond cloths, can give a touch of definition picture.

How to apply it in the design area

Using modern technologies of manufacture of concrete surfaces, manufacturers are producing material that is able to create the effect not only of natural stone, but wood, bricks, decorative tiles and other textured coatings.

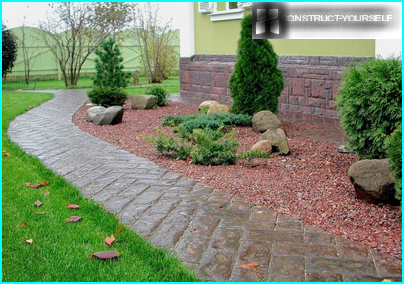

In landscape design, decorative concrete is used in the regeneration areas, making garden paths and building elements of garden landscape

Such concrete is suitable not only for the arrangement of pads and tracks. It is used in the creation of enclosures and the manufacture of small architectural forms.

Decorative fences made of concrete can have any surface, ranging from traditional brick and stone, and ending with the imitation of bas-reliefs of the Parthenon.

Scenic balusters, resembling low columns and a delicate railing as beautiful as a delicate marble and alabaster figures

Balusters made of concrete look spectacular as fences, verandas and pergolas, pillars for railing. Elegant decoration of the garden can be covered with climbing plants single columns, concrete floor vases and flower girls. And decorated with stucco fountain made of concrete and it will be the center of attention.

Cast concrete garden benches – some of the most practical structures of the garden. Depending on the style they can be easily fit into the landscape design, making elegant addition to the area.

This garden bench made of decorative concrete combines beauty and practicality – it is always a pleasure to sit down and relax

Varieties of finishing material

Depending on the options for components of the material and he created the effect there are three main types of decorative concrete.

Colored concrete

The color range of pigments used in the manufacture of decorative concrete, has more than twenty shades.

Thanks to the wide palette of shades of colored concrete can successfully complement the architectural and vegetative composition of the suburban area, having acted a worthy decoration of driveway, Parking spaces and garden paths

For colored concrete manufacturers use special pigments, which thanks to a special hardener is able to retain color fastness even under the negative effects of the environment. Often such pigments are the oxides and salts of various metals. For example, to make the concrete a greenish shade, add chromium oxide, red oxide of iron and purple – manganese oxide.

Imitation of natural stone

Using innovative technology, diamond processing, manufacturers can produce concrete, which creates the effect of full conformity with the surfaces of natural materials, laid out hundreds of years ago.

In the capable hands of a master concrete can take the shape of any natural material, whether it’s pavers, brick, slate, cobblestone and even marble

Imitation goes so believable that even with careful examination is not always possible to determine whether it is natural stone or is it his skilfully executed copy.

Covering with relief structure

Decorative concrete with an expressive structure is created by adding to the composition coarse aggregate. The desired effect is achieved by exposure of the grains that appear on the surface after the removal of tools or special solutions of the top layer.

This decorative concrete can transform an ordinary sidewalk in the old pavement, and patio in the extravagant Spanish patio

When creating a concrete with a relief structure are used aggregates of crushed marble, granite, anthracite, limestone and basalt. Striking surfaces are obtained with the use of fillers in grey, red and pink shades.

Independent production of decorative concrete

Decorative concrete is ideal for decorating paths and design of adjoining territory. With excellent quality characteristics it has a special aesthetics. In addition, a concrete coating is easy to clean, and it has a resistant and grease and oil. The grounds and alleys with such a coating does not require the installation of curbs, allowing you to save money on construction.

The grounds and alleys with such a coating does not require the installation of curbs, allowing you to save money on construction

If desired, decorative concrete can be done by their hands. Dry the mixture and shape for cooking can be purchased at any hardware store.

Version of the design depends only on your preferences. In sale you can find plastic or silicone molds that include combinations of diamonds and squares, drawings «fan», «the Exec», «animal skin», «basket weave».

Technology for creating a textured surface includes several stages:

- Substrate preparation. In the manufacture of garden paths on the marked area, remove the soil at a depth of 10 cm, put the formwork and poured a layer of gravel.

- The pouring of concrete. On the leveled surface spread grout and smooth.

- Application of color hardener. To give the surface the desired color solution sprinkle dry free flowing dyes or treated with the colour hardener, which in addition to pigments includes a core of granite or quartz sand.

- Pressing forms. On the set, but not completely frozen surface lay out forms, closely pressing them to each other. To get a clear impression of the pattern stacked shape slightly tamped. To determine the readiness of the punching of the concrete mix possible, touching it with your finger. The mixture is ready, if she’s not reaching for him.

- Cleaning cover. Stand 2-3 days, wash the concrete surface with a brush dipped in a solution with hydrochloric acid. After complete drying of the upper layer is applied to the protective structure that prevents the evaporation of moisture from the surface of fresh concrete.

In places of probable fracture should provide expansion joints, completing them at a distance of 6 meters from each other and filling the void of colorless sealant.

To prolong the service life of the concrete and significantly improve the aesthetic properties of the material, the surface should be treated with a special impregnating composition, forms a protective film.

Walkway decorative concrete can be used in 10-15 days. Ideally, the concrete surface is desirable every year to treat water-repellent solutions.