The chain saw is widely popular among the owners of country farms. Although she is not able to fully replace its «sister» with the internal combustion engine, but for its sawmill operations small amounts of the best variant not to find. The tool is easy to service: to begin, it is only necessary to connect it to the network. How to choose a chain saw with enough features but not pay extra? To exercise the right choice you must consider a number of factors, the main of which we will consider in this article.

The contents

The principle of operation of chain saws

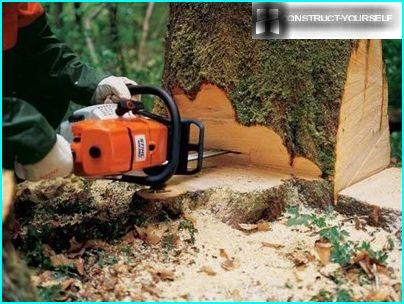

Saw — right on the farm tool that is often used in cutting branches in the garden, sawing wood and carpentry works.

Compact and user-friendly tool does not require the presence of knowledge and skills for the treatment of gasoline engine

Initially, the manual model chain saws was quite bulky and heavy. It is not surprising that the emergence of electric chain saws on the market for most consumers was enthusiastically received. In addition to ease of operation a significant advantage of the tool is that it is environmentally friendly because the process does not emit exhaust gases. This is particularly important when sawing materials in a confined space.

The main structural elements of chain saws are:

- the electric motor in the housing;

- guide rails;

- circuit;

- oil pump with oil tank.

When the unit turning on the motor creates rotational movement, which by means of bevel gear or direct drive is transmitted to the sprocket. Hosted in common with the circuit plane of the sprocket starts to rotate, whereby cutting blade easily saws the wood.

In recent years, many manufacturers equip the model of a centrifugal clutch, whereby during the loop breakage of the motor and reducer saws.

Electric chain saws are renowned for long lifetime, which is achieved due to the constant lubrication of movable elements in the process

In a special capacity chain oil by pumping the pump is supplied to the bus, which is distributed through the chain on the sprockets and cutting fabric. Many models have the function to adjust the intensity of oiling, which allows you to work with materials of different hardness.

The volume capacity is on average 120-200 ml. This volume is sufficient for 2 hours continuous operation. The task of the operator is to control the oil level in the tank, otherwise, working «dry» the motor will quickly overheat and the tool will fail.

To facilitate control of fluid volume manufacturers make the body sheer or require a special probe.

Household or professional tool?

Like any tool, the chain saw on the market of household and professional models. Professional tools have more power, allowing them to operate without interruption over long periods of time. It is better to choose frequent use.

Most professional models come with a function of maintaining a constant number of revolutions of the motor, as well as protection and comfortable handles

The only disadvantage of professional chain saws is their high price, which is often several times higher in comparison with domestic analogues.

Appliances chain saws are primarily intended for short-term activities. Time of continuous operation of the tool is limited to 10 to 15 minutes, after which you must pause, giving the engine «relax».

The simple design of these models and used in the manufacture of inexpensive materials significantly reduce the cost of household and chain power saws

Not to miscalculate, before you choose a chain saw, determine the estimated scope of work and frequency of use of the unit. If you need a tool for seasonal work in the country, it is possible to be limited to household option.

Parameters selection of quality saws

The modern market offers a wide variety of models. Among famous brands proven producers are the most popular: Bosch, Sparky, Patriot… there are also less popular brands, which are often not inferior to the presented functions. Therefore, when choosing chain saws should be guided not only razreklamiruete brand, but also the performance of a specific model.

Option #1 — the location and power of the engine

The first thing you should pay attention when choosing the tool – motor power. This parameter determines not only the performance but also its longevity.

If voltage surges in your power supply are quite common, better choose a tool with sufficient power. The engine for this chain saws at low voltage will not overheat, posing rated power.

Engine power chain power saws household option can vary in the range of 1.5-2 kW, and professional – to achieve 3.5 kW

When an unstable voltage experts recommend to choose a model with a thermal control that automatically shut off the tool. Thermostat activated when the temperature of the motor windings reaches a predetermined threshold. But it is worth considering that if too frequent disconnection in unstable voltage conditions and reduced performance of the unit.

If you focus on the location of the engine in designs, it can be:

- The cross – axis of the motor is perpendicular to the width of the machine and its centre of gravity is slightly displaced. When working with such a tool will always have to maintain a balance. Comfortable to work with him in the vertical plane when doing the downwards cut.

- The longitudinal design represents a straight line in which all components well balanced. This design provides excellent balancing of the canvas at the corners, giving the tool greater maneuverability.

Saw blades with a transverse engine is designed for General use. The power of such tools is around 2kW, and the weight does not exceed 4 kg.

Saw blades with a longitudinal arrangement of the engine is indispensable in carpentry.

The absence of the speaker from the side of the engine simplifies the work with the tool, but increases the weight of the unit, the value of which can reach 6 kg

From the considerable weight of the hand will tire quickly, and therefore such a tool is not very convenient to be managed within a few hours of uninterrupted work is worth considering.

Option #2 — adjustment of chain tension

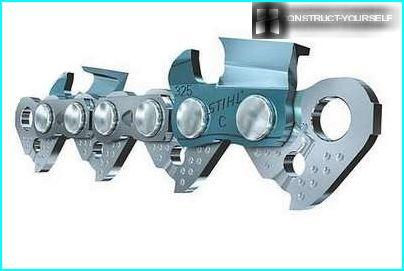

In the manufacture of power saws use low profile chains. Though they have lower performance, but it is good that the tool is subjected to less vibrations, making it safer to operate.

The correct tension will affect the performance and safety of the work, so in the process of operation of chain saws have to pull quite often

In sale there are models in two variants of execution of the chain tension:

- Classic – for tensioning the chain holding the tire and loosen screws using a flat screwdriver to gently move it. It’s a pretty laborious method, time-consuming and requires the availability of the necessary tools.

- Simplified – chain tension is achieved by loosening the nuts and removing the tire by means of the slider.

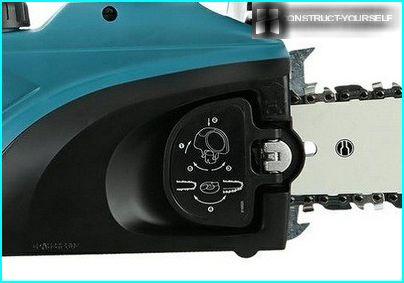

Lubrication the saw unit in the current model is carried out using the oil pump automatically. The pump is driven simultaneously with turning on the saw. This greatly simplifies the care unit. The task of the owner of the drinking – to monitor the level of oil liquid and pour it as needed.

The presence on the side of the lever makes it easy to adjust tension system is convenient because does not require the use of special tools

Option #3 — the length of the bus

Working the tire on which is fixed a chain, may have various modifications. Length of bus is directly connected with the power tool. It can reach 30 – 45 cm Given that the suburban area is unlikely to have to cut thick logs, the best option for economic purposes is considered a bus length of 40 see Tools bus of greater length will be much heavier, more powerful and therefore more expensive.

The quality of the cut depends on the thickness of blades.

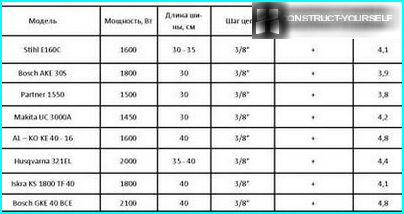

Tools for domestic use a standard pitch of the teeth is 3/8 of an inch: the thicker the chain is, the stronger must be the motor

Saws from different manufacturers depending on the performance of the tool can be installed different types of chains and tires. Over time, the movable elements will wear out and require replacement. Therefore, in order to prevent problems with search of detail, choose power tools with the most common type of chains.

Option #4 — smooth start-up

System starting and braking of the engine – perhaps the most extreme modes of the plant. The reason for this is that in these moments, through the motor winding are dosage of current, which significantly reduce its resources.

Greatly facilitates the work and protects the engine from extreme loads, the system soft start, which limits inrush current, allowing the motor to gain momentum gradually

System soft start extends «life» unit.

The presence of the inertia brake allows for fractions of a second to stop the motor when switching off the tool, thereby reducing energy consumption.

Option #5 — security

Any power saw for woodwork is a potentially dangerous tool. Therefore, when choosing a unit, it is important to protect yourself from possible injury while using a tool.

When choosing a power tool, pay attention to the presence of lock accidental activation. It will protect you from danger if you are not comfortable took the instrument with one hand or after switching on found that is not yet ready to work with him.

When working with a chain saw special danger may be «reverse punch». It arises at the moment of contact of the end of the bus with a solid timber surface, in which the tool is abruptly thrown back, and its moving chain can injure the operator.

To warn «reverse punch» modern models are equipped by system of automatic brakes, which is a designed in the form of a flap lever located under the arm

The automatic brake is actuated by the slipping of the hands when there «reverse punch»: when pressure in the shield triggered spring that includes a brake and stops the chain.

How not to break freshly bought tool?

Professional repair tools point out that most electric chain saws fail in the spring. This is easily explained by the fact that during the cold winter months in the windings of the motor of the tool collects the condensate. A drop of moisture and cause a short circuit when you turn on the unit. To prevent this problem, «stand» tool before starting work in a warm room. For this it is put in the room at least the day before the date of inclusion.

Frequent provocateur removal tool of the system is the voltage drop of the network. If the voltage and development unit of nominal power as a result of intense heat may just melt the insulation or to close the anchor. Therefore, when working with the tool, it is important to monitor the stability of the current and periodically to give the unit «relax».

The chain saw is simple and easy to use tool. With proper care and observance of safety rules it will last more than 5 years without additional costs.