On a hot Sunny day, when the walls of a country house thoroughly warmed up and do not give desired coolness, many of us often there is a desire to find a place to relax in the fresh air. A good solution to the arrangement of such a cozy corner outdoors will be a gazebo made of metal with your hands. Elegant design is not close to a picturesque landscape or view of the house and will become an organic complement of the architectural ensemble.

The contents

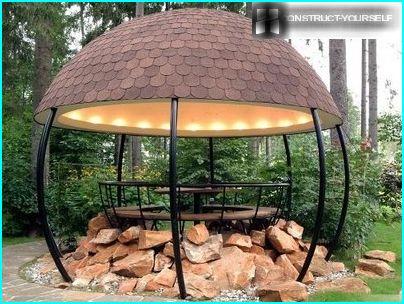

Beautifully designed metal gazebos for the garden, acting as aesthetic additions a landscape design that can emphasize the taste of the owner. The variety of shapes and sizes of metal garden arbors is amazing. Decoration of suburban areas be like traditional round, square, six – and octagonal gazebos, as well as original designs of the most unusual design solutions.

Depending on the intentions of the designer of the gazebo can be decorated with various decorative elements: art forging, hanging planter basket with flowers…

The main advantage of the gazebo to give of metal is its strength and durability. Convenient construction capable of regularly last for one season. The only thing required to extend their service life, periodically inspect and promptly clean up areas where there are signs of corrosion.

The rigidity of the frame metal gazebos to prevent the change of the geometrical sizes, which often arise due to uneven subsidence under the influence of seasonal changes.

Depending on the design solution and the functional purpose of the gazebo, a covered area can be set any attributes for the rest, starting with garden furniture and ending with the grill or stove BBQ

Design options of roof metal frame many: slate, metal sheet, polycarbonate… the Choice is limited only by the preferences and financial capabilities of the host.

Gazebo can be a permanent structure or portable temporary structures. In the first case they are installed on a Foundation: slab or crawlspace Foundation. Portable design, easy to dismantle and clean the onset of cold weather, are installed directly on the ground.

Hand made metal gazebo – at least the pride of its owner. And therefore propose to consider the main stages of construction as required in the farm design.

Step-by-step construction of a gazebo with a multi-faceted roof

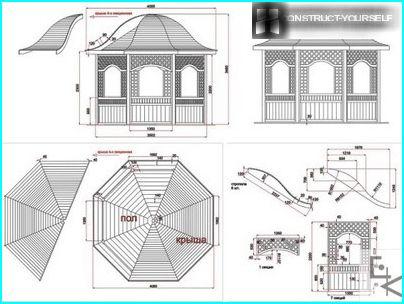

Hexagonal gazebo – a classic that never loses its relevance over several decades. This cozy design has a number of advantages, principal among which are: elegance, roominess, strength and ease of construction.

This eight – or six-sided design is analogous to a round model of the gazebo, but unlike the latter is much easier from the point of view of construction

To make the metal gazebo yourself, there is nothing difficult. You only need to have a specialized tool and possess minimal skills plumbing.

Step #1 — preparation of all necessary materials

For the manufacture of metal gazebo will need:

- Hollow tubes with a wall thickness of 2-4 mm for racks design (rectangular or square cross-section);

- Mounting brackets;

- Bars for sheathing;

- Roofing material (wave polycarbonate, soft tile…);

- Siding for wall cladding;

- The rotation or garden auger;

- Electrodes;

- Drill bits for metal;

- Building level;

- Sand and cement;

- Paint on metal.

Among the tools we will need: grinder, welder, drill or a power drill, galvanized screws and screwdriver.

Step #2 — site selection and preparation of substrate

The main condition of selection of space for a gazebo to the owners and guests feel cozy and comfortable, enjoying the most beautiful views of the country site.

Place under the arrangement of pavilions on the site can be selected any: under the canopy of trees in the garden, near the pond or near the entrance to the house

Thinking through the design of the gazebo, you must decide for yourself whether it will be open ventilated or totally enclosed, with lighting or without. To visualize the project and determine the dimensions of the future construction it is desirable to make a drawing of the building. Drawing, made to scale, will allow to calculate the required amount of pipes to the installation main frame, and additional couplers are of smaller cross section for arrangement of the roof and cross members.

The definition of the dimensions of the doorway:

- the height is calculated, based on average human height (1.8-2.0 m);

- opening width approximately equal to the standard size door to the apartment (0.9-1.0 meter).

The site selected under the arrangement of the arbors, clearing of debris and tree roots.

With cleared of debris and the remnants of the plant site remove the fertile layer of soil, which we use to podsypanina in flower beds and alignment changes on the site

Clearing the ground and removing the 15-20 cm layer of soil, the bottom is formed «pit» sleeps 5-8 cm layer of sand, pour water and carefully stamped. On the basis of sand, you can just lay paving stones or paving slabs, or to construct the concrete pad. To do this, from the boards forming the formwork, fixing it driven into the ground on the outside of the pegs. Fill the area with concrete and leave until fully cured for a few days.

When building a site, with an area of over two square meters, it is necessary to provide thermal expansion joints. For the casing boards are installed, maintaining an interval of 1 meter, and fill space with cement mortar. After curing of concrete, remove boards, and the gaps sealed with a liquid solution.

Step #3 — installation of support stands

After completion of works on arrangement of the floor, around the perimeter of the grounds set label where we will place the support poles. The number of racks must match the number of corners of the gazebo.

For the erection of support posts in scheduled areas by means of rotation or a garden auger dig holes with a depth of about 80 inches

The support struts are preferably sunk below the level of freezing of the soil that is 80 -100 cm excavated pits covered with a layer of sand and gravel. In the center of the hole install metal poles. Using a level, defined by their verticality, then fill the voids with cement mortar.

Another possible embodiment of the construction of stands, wherein in the planned places at a depth below the level of soil freezing install pier Foundation – concrete columns with the mortgage. These mortgages will be welded metal supports.

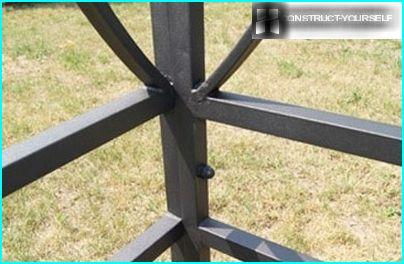

After the installation of the vertical struts can be welded to the horizontal crossmember of which may be metal tubes or rods

Prozhiliny placed in two rows, between which the width of 1.2-1.5 meters. They will be further secured sheathing (boards, molded polycarbonate).

The metal structure can be assembled as by screws and bolts or by welding. The choice depends on whether the host is able to work with a welding machine or whether it has the ability to invite an experienced welder. The main advantage of bolted connection is the possibility of dismantling the structures for the winter. But at the same time we should not forget that in the process of operation design of bolted joints have to constantly pull up.

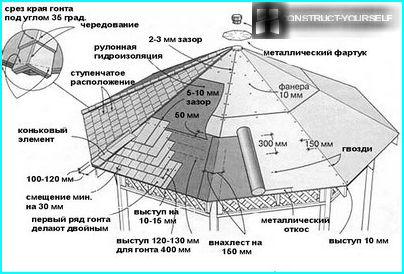

Step #4 — the arrangement of the hexagonal roof design

To the flowing from the roof water filled design, cross joists are placed so that they are 50 cm out from each end.

For arrangement of proper eight – or six-sided roof to the support posts welded cross beams, placing them at a distance of two meters from each other

The joists are welded to the metal crossbars, and then, based on the level, apply and fasten the rafters

The simplest version of the arrangement of the roof sheathing sheets of polycarbonate. To do this, in the metal rafters make the holes for fastening of roofing material. To set the first sheet of roof, put two leaves on them look forward and set your desired angle and go. After that, remove the first sheet and the second fixing screws. All sheets of the roof fasten it in turns to stiffen fastening them together using two waves.

Gazebo is almost ready. It remains to attach the side panel and paint the metal frame members. Paint the finished design can be achieved by powder coating. Gives good results and traditional painting, in which the surface of the first layer of primer, and then paint on metal.

Video examples of the construction of other structures

Example #1:

Example #2: