Private garden – great place for work and relaxation. For complete holiday relaxation people have come up with various accessories from swings to hammock. Classic comfortable item of furniture are chairs. But someone brilliant has managed to make its design the addition, which made it even easier: was born the rocking chair. This model allows you to relax all the muscles and the slow and rhythmic rocking has a pleasant thinking, soothes and lulls. The rocking chair was so popular that since its invention, many variations and modifications. Moreover, it was found that the rocking chair are made of different materials – is not a myth.

The contents

Popular models of rocking chairs

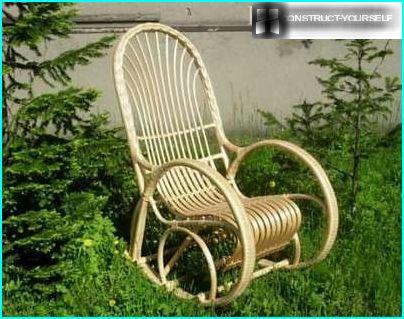

To create classic models chairs need wicker willow. Openwork, lightweight design looks great against the greenery of the country and blending with the interior of the garden house or gazebo. The drawback with this lightweight and durable products one – fear of the excess moisture.

Make easy and seemingly simple chair from willow twigs not so easy. You need to be able to prepare the material, and the technique of weaving requires special skills

Rattan is a flexible vine that grows in Southeast Asia. Rattan weave is also wonderful and very beautiful chairs. Beauty they are not inferior to willow that cannot be said about strength. No screws, no nails when creating rattan furniture is not applied. All connections to stay only because of the glue and artful binding.

Rattan as raw material in our stores is not for sale. This rocking chair for the owner of the cottages is a good buy, not the product the manufacture of which he can show their creativity

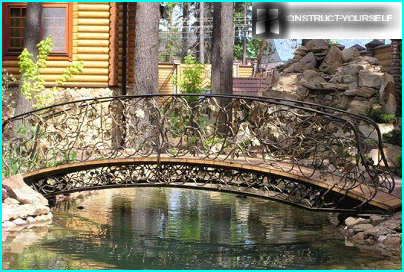

If we talk about the strength and durability of the product, it is an example of a reliable furniture it can happen that a model designed from forged metal. Delicate lace construction will decorate any garden.

The main advantage of this model is its durability. The main but not the only one. I agree that this thing is like a delicate silver decoration

Rocking chairs are not only used as garden furniture. A distinctive feature of office chairs are respectability and reliability.

Office workers also value good rocking chair as accessories that help to fully relax from the busy work. Of course, office models vary from country option

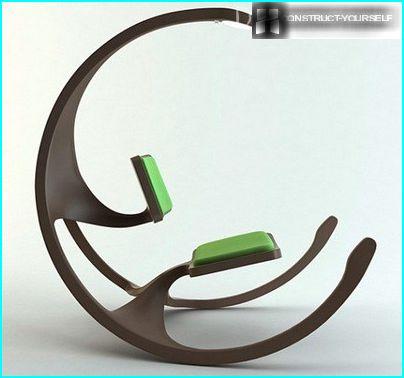

There are designer models of rocking chairs, made in the style of hi-tech.

Very interesting and, most importantly, you need a functional model. Combines a comfortable rocking chair and a directional lamp

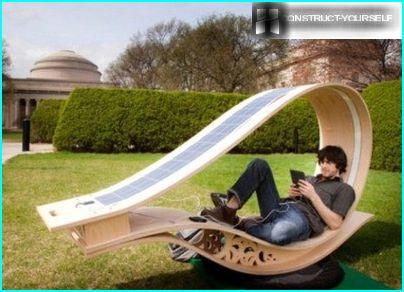

Some ultra-modern designs of rocking chairs truly unique. As more simple models, they provide its wearer comfort, but also, independence from energy sources. This product is equipped with solar panels, allows you to spend time with comfort and benefit.

For the base of this design you can use thick plywood, and for its upper part polycarbonate. Find solar panels today is not a problem.

Master class: swing chair for two

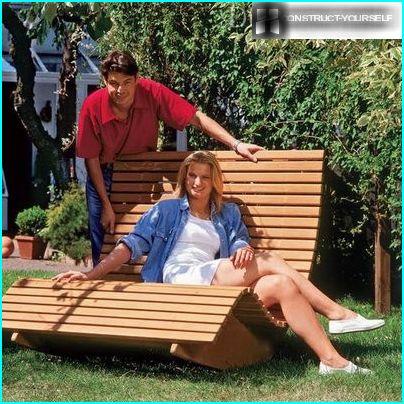

Double rocking chair more like a sofa. If this is a convenient construction to put some pillows or a throw blanket, nothing better for holiday vacation is simply not to find. We will tell you how to make a rocking chair with their hands.

Who said to enjoy the comfort of a rocking chair can only be alone? It is this model good for two people

Step #1 — prepare tools

To make a quality rocking chair is not as difficult as it seems. Having all the necessary tools and stocking quality materials, you can slowly do it herself. What tools will be needed for this job?

- Electric jig saw complete with saw blade for wood.

- The disk sander. It needs the will of nozzles with different granularity. In fact, manual mill may also be necessary, but if you have a large number of coarse sandpaper and with sufficient power sander, you can do without it.

- Screwdriver with bit set wood bits.

- Right angle, having a long measuring range.

- Roulette.

- Hammer.

- Spatula.

- The brush and pencil.

Proper organization of work assumes that all of these tools will be literally at your fingertips.

Stage #2 — draw the drawing

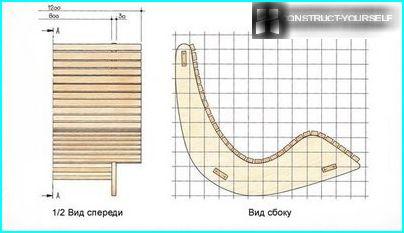

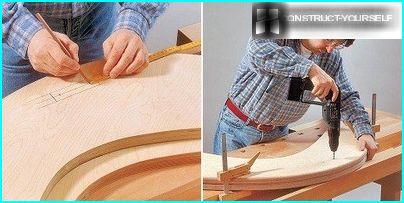

Any responsible work begins with the manufacture of drawing. It is necessary in order to correctly calculate the material requirement. However, the drawing is already there. Metric on the grid, a step which is 100mm, placed pattern side of the chair. It is best to transfer the drawing onto the paper and cut the pattern by which it will be easier to put the outline on the plywood.

Drawing a great rocking chair that you can do with your skillful hands, is performed on a metric grid step equal to 100 mm

Small inaccuracies are acceptable, it is important not to be mistaken in one thing: the sidewalls have to be the same on the bowl, the lower side should be no protruding corners.

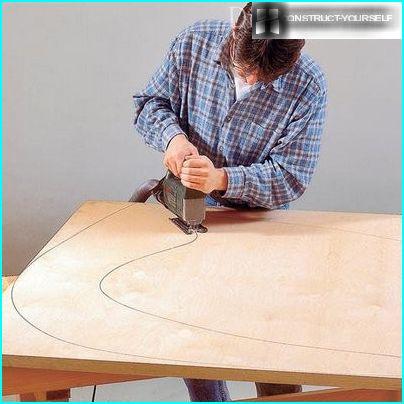

Step #3 — cutting blanks from plywood and lumber

For the manufacture of ties, the rings and the sidewalls need eurotuner, a thickness of 30 mm. Side, as mentioned, are cut with a jigsaw, strictly according to the pattern. The size of each of the three rings – 800х120 mm.

Now you need to cut parts of the bars that will later constitute the surface of the seat and back rocking chair. For this, the beam size 50х25 mm, from which we will cut 35 blanks at 1200 mm each. Before purchasing the necessary material, learn what is the standard length of such a bar in your stores.

On the basis of the proposed drawing you need to make the template, which should be applied to the contour of the sides of the seat to the plywood

Common moldings you need, you can easily calculate yourself. Observe the multiplicity, to the cutting of blanks was not a large amount of residues. Better your chair will be slightly narrower than originally planned. For example, when the standard length is 2.4 meters length one piece will be 1195 mm (subtracted the thickness of the cut and subsequent processing).

With the fasteners all just. Need:

- confirmati (evrovinty) 12 pieces, size 5х120мм;

- screws 140 pieces, size 4х45.

In fact, the initial part of the work is already behind, but still have to work thoroughly to get the desired result. In the process, you will need linseed oil, wood varnish, putty, antiseptics, who also need to buy in advance.

Step #4 — pre-treatment of parts

Start sanding all of the parts and removal of small chamfers. If your sander is powerful enough and you know how to use it, this procedure will not take you much time. Given the fact that the rocking chair will be on the street, special attention must be paid to the ends of all the elements, to protect them from damp, exposure which they undoubtedly will be.

Pre-treatment of parts is not only in their sanding and chamfering. You need to take all measures in order to protect end parts of the elements from rotting

The ends of the parts need to be impregnated with hot linseed oil, and the wood fibers on them slightly to flatten with a hammer. So there will be less moisture to absorb. For the ends processing of coating processing should be performed twice before the General Assembly.

Step #5 — Assembly design

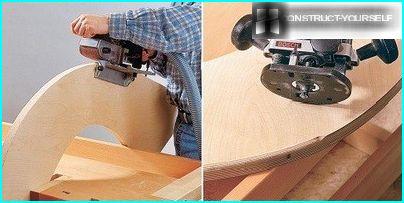

No specific standards in the manufacture of this item of garden furniture is not provided. Holes for rails are spaced as required by the logic: the head, the middle part of the outer arc sides and footboard. The drawer sides are fastened to the sidewalls by means of confirmation. For this purpose, the sidewalls are doing a preliminary layout, and then two sides are aligned, and their planes is drilled a through hole with a drill of 8 mm For the holes in the end rings, a drill of 5 mm. you can Now pull the frame of the chair with eurowindow.

The holes for the drawer sides need to lay out, after which the two sides fold together and drilled a neat through-holes

Now let’s talk about how to drill the bars forming the seat and the backrest. We have exactly 35 pieces. You need to drill each block with 4 holes (two on each side). And this 140 symmetrical holes.

To simplify the problem, use «the conductor» — a device for marking a large number of homogeneous parts. We make it very simple: take a scrap of the same timber, not shorter than 250 mm, drill holes in it for the template, whose diameter should be the same as the pencil for marking. With the face and one of the side parts «the conductor» nail cutting plywood, which will serve as a limiter, not giving to miss the process of marking. «The conductor» ready.

Assembly is the most time-consuming part of making rocking chairs. However, «the conductor» will help you to ease the process of drilling symmetrical holes

Here is the chair in the final stages of work. Of course, in this form it is still impossible to exploit. You need to take steps to protect it from the weather

«The conductor» will be used for marking holes, drilling through it is impossible, because the drill bit can break the formulaic openings and details will have to countersink. If you take a drill bit 3,5h30 with the countersink, it will be ready markup to make a hole so, it is needed.

According to the drawing, between the bars should be a gap of 15 mm. to avoid bias it is necessary to mark on the side of the seat distance, which will correspond to the six bars along with intermediate intervals, and check the coincidence of the template ear thickness. If match, you can continue to strengthen. Otherwise, adjustments should be made. Chetyrehkilometrovoy screw on wood well-kept Evrofinance. But given the fact that the frequency of mounting high is better to use a three-millimeter drill bit.

Step #6 — finishing the finished product

The holes above the screws must be carefully zashpatlevat. Next in line will be processing three antiseptic coating of the product with a waterproof varnish. You must work very diligently. Remember how in this chair already invested your labor. After all, you want it to lasts as long as possible? Then try!

If you have small children, you can get them to work on filler holes over the screws, but carefully inspect the model for damage to eliminate them for yourself

Moving the chair runners

You may have noticed that all the above models share a common working principle. The trick is that as the base, these horns are used curved runners. How to make a rocking chair without runners? It turns out that this possibility is also available. Watch this video and you will get an idea of how it’s done.