The contents

- The advantages of furnace stoves

- Tools for the manufacture of stoves in the garage

- Materials for the manufacture of stoves in the garage

- Flue installation

- Oven on community service

- The procedure of manufacturing stoves in the garage

- Stove from a gas cylinder

For many motorists, the garage is not just a place where you can leave your car. Many spend a lot of free time in the garage for auto repair or simply for spiritual gatherings with friends. But in the cold season to be a long time in a place very difficult. However, the exit can always be found. Putting the stove in the garage, made with your own hands, even in extreme cold to relax in comfort in the garage. Moreover, this furnace can be made of different materials that are there almost every host.

The advantages of furnace stoves ↑

The heated room is of limited space. So the stove in the garage is the best option. In addition to compact dimensions, this stove has the following positive aspects:

- Quick heated;

- The possibility of using both liquid and solid fuel;

- The stove heated the room long keeps heat inside;

- For the construction and installation does not require expensive materials and special skills.

Tools for the manufacture of stoves in the garage ↑

In order to make the stove into the garage to get the following minimum set of tools:

- Welder. It is recommended to use the tool with power 200 amps;

- The mask and suit for welding;

- Special hammer to separate the slag;

- Bulgarian;

- Standard hammer, pliers and a chisel;

- Steel brush;

- Drill with drill bits;

- Roulette to required measurements.

Materials for the manufacture of stoves in the garage ↑

For garage stoves can be conventional gas cylinder, metal sheets, steel tanks and pipes. You can also build your own hands of the brick oven. However, this method requires much more effort and money spent.

Flue installation ↑

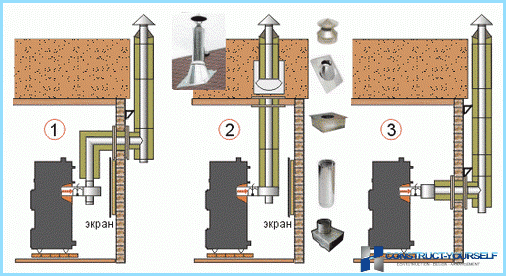

Before installing any furnace should build a chimney that will output all the products of combustion. To understand how to make a chimney for a stove in the garage, you have to determine its type. There are three options for installation of the chimney, each of which has its advantages and disadvantages.

The first option when some part of the tube is inside, and the rest exits through the side wall, is used most often. In this case, the inner tube also plays a role in the heating and serves as a battery. Besides, to make a conclusion through the wall quite easily.

The second diagram shows a tube that is completely inside the garage and is discharged to the outside through the roof. Despite the fact that a stove with this chimney warm the room better, do it less often. This is because the process is more time consuming. In addition, when defective sealing of gaps between chimney and roof, possible leak.

The third option is the installation of the chimney with their hands not as efficient at heat transfer, but much safer. Due to the fact that the pipe is directly conducted away, the fire risk is reduced to almost zero. But at this end of his dignity, and the disadvantages, unfortunately, no. This type quickly cools down and draws heat from the furnace. Thus, for a high-quality heating of the garage need more time and fuel.

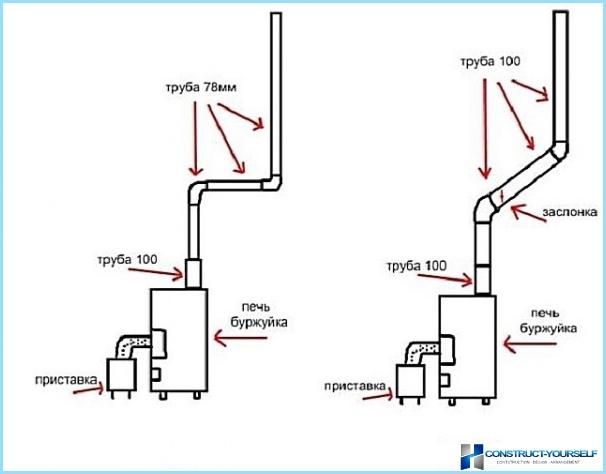

Having defined the place of installation of stoves and flue exit, you need to make a drawing or a rough drawing. An example is shown in the figure below.

After selecting a chimney can start to build stoves.

Oven for testing ↑

Engine oil after usage can also come in handy. With it, you can greatly insulate the garage. But this will require to build a special stove, which is somewhat different from other types of.

This option is suitable in case if it is not possible to use coal or wood.

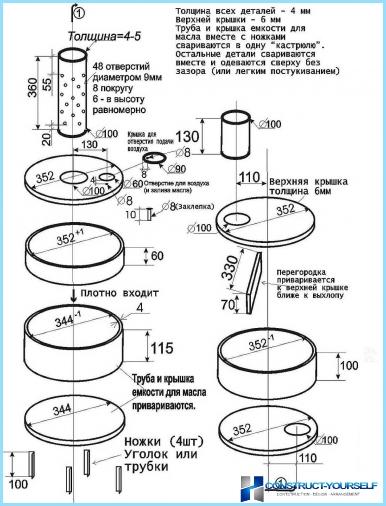

The main component for the manufacture of a sheet steel with a thickness of 5 mm. of it will be stripped of parts that will be produced by the stove. In addition, you will need a metal pipe, which will create part of the furnace and the chimney.

Will not be difficult to put a stove in the garage with their hands, using the drawing, in which parameters are specified all the necessary details.

The procedure of manufacturing stoves in the garage ↑

Begin work necessary with a marking on the sheet surface. It is important that all information is accurate. After that, the grinder cut all the parts and clean them from chipping.

The procedure works as follows:

- After cutting out the components, it is necessary to engage the pipe. Choosing the correct size, across the surface of the drilled hole. This detail serves as a connecting link between the upper and lower part of the furnace.

- After the construction of the upper tank there is a round hole (left of center) that you want to connect stoves to the chimney. The underside of the tank, in contrast, has a hole on the right side. It will be installed connecting pipe.

- When the upper tank is ready, to the bottom of the welded pipe.

- Then you can start installation the bottom. After cutting parts from the sheet in the upper circle you need to cut two holes. First, it was the center that will connect. The second is installed with a movable cover. Through this neck, the stove is fed fuel.

- After prodelyvanija to the bottom of the legs and its connection with the pipe, the furnace is almost ready. Are only the finishing touches. Before joining the chimney, you should clean up the seams and to cover the heat-resistant stove paint. These actions not only give a more acceptable appearance, but also protect the surface from corrosion.

Stove from a gas cylinder ↑

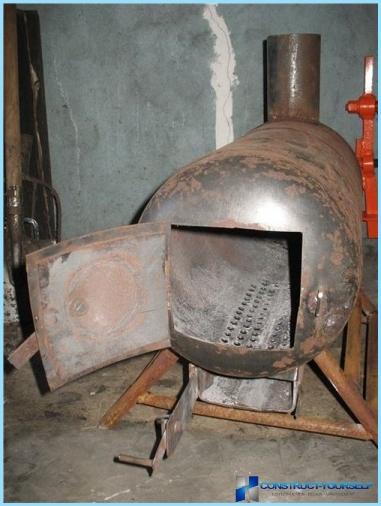

Old and unnecessary gas cylinder is not necessary to throw out. It is possible their hands to make an efficient stove potbelly stove for a garage with a high level of heat.

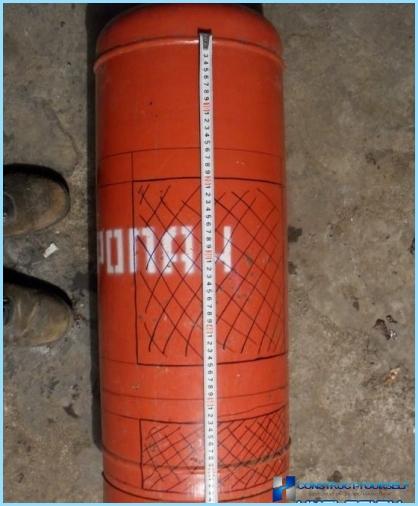

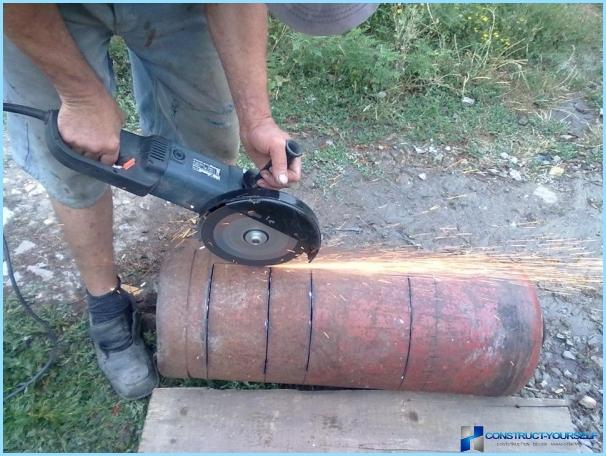

The first thing to do is to cut off the excess part of the grinder.

Do it better in the open air, since the condensate has a sharp and unpleasant smell, which for a long time disappears from the room. Finally remove the gas will help water. To do this you must fill the tank to the eyeballs, turn and drain all the water. You can then safely start working.

The first step is to determine the installation option. There are only two:

- Vertical;

- Horizontal

Garage is equally good for both.

Horizontal stove in the garage ↑

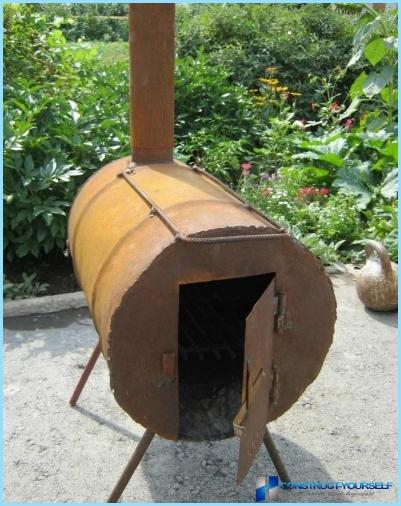

The order of performance in the production of furnace stoves for the garage:

- Manufacturing horizontal furnace begins with cutting the upper part of the cylinder. After which inside is mounted a grate.

- To make this grid you can easily with your hands. For this purpose the valve. If not, you can replace the large wire, which is bent in the shape of a snake. To her inside, welded the grate.

- Then you can move on to mounting the front of the stove. It is necessary to take steel sheet, minimum thickness of 4 mm, and cut out a circle the size of which must correspond to the diameter of the cylinder. On the resulting circle, you must do 2 holes. The first will serve for fuel, and the second, for admission of air into the combustion chamber.

- Then on the lid are mounted the hinge on which the door is mounted. To improve the quality, it is recommended to cover its asbestos cord.

- The resulting structure is welded to the cylinder.

- The final step is to install a pipe to connect to chimney. For this purpose, in the rear of the stove is a hole in which is installed pipe. After that, parts are welded to each other. Oven ready.

Vertical oven-stove ↑

This homemade wood stove for a garage, made with their own hands, more convenient to use. But it needs more effort for its manufacture.

Before beginning work on the tank should be marking future openings. Look the drawings as follows.

Dimensions can be arbitrary. Importantly, the holes were rectangular in shape. In this case, the combustion process will be somewhat better.

Then, using the grinder to cut the holes.

Now you set inside the grille. It’s easier to cut off the top of future stoves. However, you can do without it. You can insert it through the newly made holes. It should be noted that it will be more difficult.

When this procedure is completed, you can install the door. The process is exactly the same as when installing horizontal stoves.

The conclusion will be breaching the top of the hole under the chimney and subsequent welding to the pipe.

A similar stove in the garage with his own hands excellent burning firewood and other solid fuels. With its help, even in extreme cold you can Tinker with the car, or just having fun to spend your free time.

The potbelly stove from an old barrel ↑

In addition to the gas cylinder you can use an old metal barrel. The principle of operation is almost the same. In the same way as the previous version, to put in the garage stove can be both vertically and horizontally.

For more information about how their hands to make a quality oven for your own garage, you can get from the video.

Following all safety rules, with the construction of a furnace to handle even a novice master. And if you have a full set of instruments, the procedure will take not much time.