The contents

For motorists, the garage often becomes a second home. Besides the main purpose – vehicle storage, garage used to repair cars and to repair tools and household appliances, and for other purposes. Here usually are demolished already useless things, old furniture, which is a pity to throw out, any appliances that need fixing, up old bikes and even inflatable boats fishing enthusiasts. The list stored in the garage of junk at everyone, however, the number usually increases and greatly complicates our lives.

Why do you need shelving for garage ↑

Among the main reasons to install garage shelving note the following:

- First, there are difficulties upon arrival and exit the car.

- Second, the accumulation of old things is hard to find the right tools to reach the currently required parts.

- Third, the aesthetic appearance of the garage leaves much to be desired, in addition, such a chaos in the room pretty annoying and takes a lot of time.

- Fourth, in the cluttered garage increases the risk of fire, and far harder to resolve inflammation, because the garage is usually stored and flammable materials: gasoline, oil.

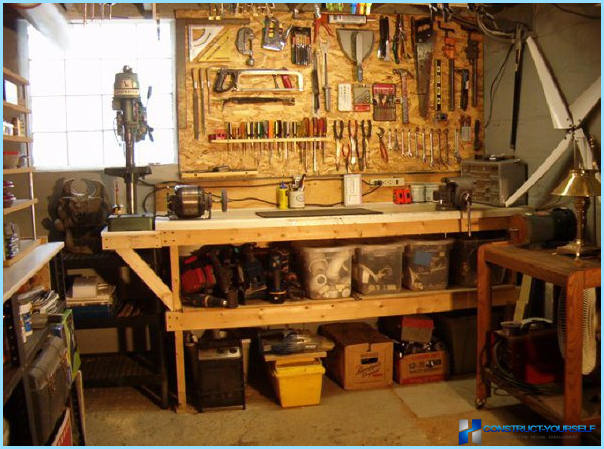

Of course, there are exceptions. Some owners of garages manage to keep them in perfect order, where everything is laid out on the shelves, hung on hooks, sorted by purpose. If you notice, in these areas are usually along the walls are shelves, which laid out all the contents of the garage.

As practice shows, the rack remains the best option for storage of tools, spare parts and other garage equipment. It has sufficient capacity, does not occupy much space, open access to the shelves of the rack allows you to quickly find the desired object. The rack will conveniently store and large items, and enough heavy objects.

If you decide to organize the contents of the garage, a rack makes it much easier to restore order. And to figure out what is most suitable for your garage, you need to familiarize yourself with the options.

Conventionally available types of racking are:

- stationary;

- teams;

- mobile;

- rotating.

The stationary structure is mounted in the garage on a permanent place for greater stability can be fixed to the wall, typically is molded. The advantages of this scheme include the high strength and the possibility of placing the maximum of heavy parts and tools. It is made from strong durable materials and will easily withstand operation for several decades.

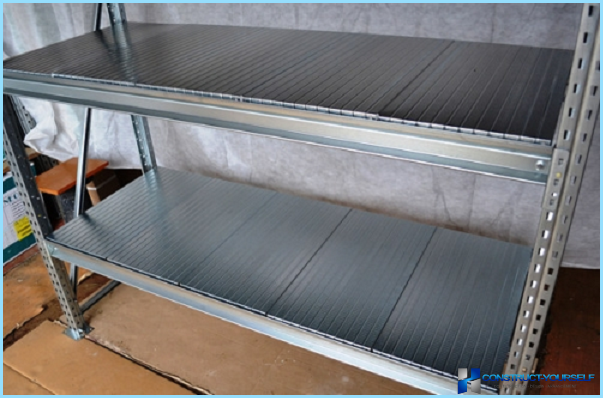

Most sales teams have the metal shelving for the garage. They are made from perforated metal racks, which are attached to the horizontal shelves. Usually they are sold in disassembled form with a set of necessary fasteners. Assembly this option is available to everyone, not even owning a special repair skills. The advantages include the fact that you can optionally change the height of the shelves depending on your needs. This way you will be able to fold for storage and spare set of rubber, and large tools.

Mobile variants have small wheels so you can move the entire set of tools in the garage, and if necessary even to roll out beyond it. The advantage of this design is its mobility, the ability to easily rearrange in the garage with a single garage to another without unloading its contents, and also to pick from all the tools to the place of repair. But its load capacity is inferior to the solid variant. This rack is also sold in parts, going with a screwdriver directly at the garage, as the designer.

The rotating rack can be purchased for storing lightweight small tools and parts, as well as nails, bolts, screws and other small things. It has a small footprint, but you will be easy to find the desired item by turning the rack around the axis of rotation. At the same time you can free up space on a large shelf for massive objects.

Optionally, you can not buy ready-made shelving for the garage and do it yourself.

Before you buy or make a rack, you need to determine what place in the garage you can under it to select. It is best to place it along one of the walls on the entire length of the wall. Height limited to the height of the ceiling in the garage, and the width is determined by your needs. It is desirable to keep the distance between the rack and car not less than 80cm, to have free access to the shelves, as well as to protect the car from possible fall from shelves of heavy objects.

In addition to size, determine your anticipated load on the structure, consider that you will be folding. Maybe for ease of placement of the instruments need not one, but two of the rack from opposite walls, or a solid one stationary and one mobile. All this is determined from the point of view of convenience depends on the kind of work performed in the garage, and for no other purposes use it.

Shelving for garage is easy to do with their hands. If you are into that stuff, it’d be good practice.

How to make shelving for the garage with his own hands ^ a

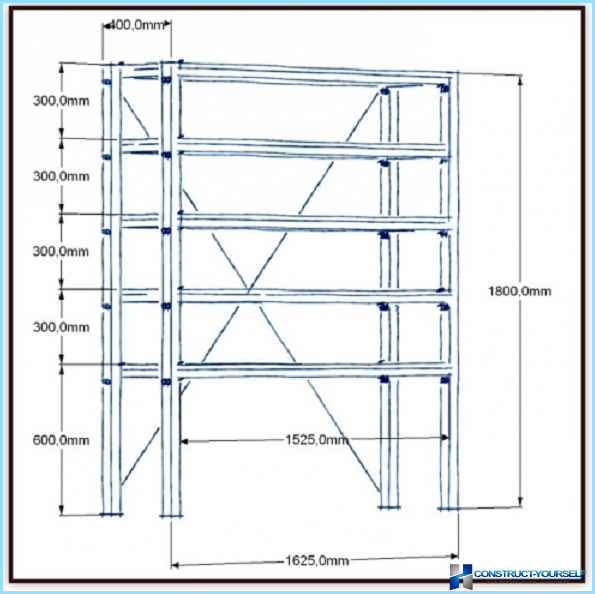

Before the construction necessary to determine the dimensions and make a drawing with dimensions. Length of the rack depends on the length of the wall or to your needs. Height limited to the height of the ceiling in the garage.

Flange width, i.e. the distance between the vertical posts, usually made about 1 meter, and if you want to increase it up to 1.5 meters, no more, as this will reduce the strength of the shelves.

Depth of shelves generally range from 30 to 60cm, depending on your individual preferences. The height of the shelves can be different, for example, the top shelf can be done up to about 30cm for storing small and lightweight items. Middle shelf – до60см height, and the height of the bottom increase to 1 meter, to fit large items and heavy spare parts.

For the construction of the rack it is better to use durable and reliable materials that can withstand high mechanical loads, that they have served the maximum years.

Tools for the manufacture of metal shelving with wood shelves:

- ruler, level, tape measure;

- Bulgarian;

- welding machine;

- construction pencil;

- hand saw;

- paint brush;

- drill, hammer, screwdriver, pliers.

To build a set of racks would need to purchase the metal rack (metal rod or tube), metal parts, boards for shelves or thick plywood (chipboard) with five electrodes for electric welding, primer for metal and paint, dowels and brackets (if you plan to mount the rack to the wall).

Start to work ↑

Oddly enough, but the most difficult to manufacture racks for garage is the detailed planning and thinking through where and how must be placed tools, parts, paint materials, old stuff, to have everything at hand and doesn’t interfere.

For the manufacture of shelving in the garage will stick to the rough order of work:

- Grinder to cut metal into the required segments specified in the drawing.

- On vertical posts mark the site of attachment of the shelves.

- On the vertical supports by welding weld metal corners. Before welding the parts, it is necessary to ensure the symmetry of their arrangement on adjacent racks so the shelf did not work inclined.

- After it is welded metal base, it must be well primed, and then painted to protect from rust.

- The size of the shelves to cut wooden planks to make shelves out of boards, plywood or OSB.

- Below the shelf was more stable, upright brackets fixed to the wall of the garage.

Even easier going wooden shelves in the garage. To install them need to be concreted into the floor and wall corners 50 and a height of 10-15cm. The very supporting structure made from timber 75-100mm. If the bottom shelf to pick up in size by 70% of the diameter of the tire of the vehicle, this construction can be used in the garage as a shelf for the wheels.