The contents

- The types of stoves burzhuek

- Cast iron stoves to give

- Wood stove from a gas cylinder with your hands

Most owners of country houses and garages sooner or later face the problem of heating. Well if the structure is connected to the Central heating or it is possible to install the boiler. It is justified if you live in the house for a long time. But what if you plan to live in the house only in the summer season or on weekends? In this case, a great solution to the heating problems will be baking stove.

The stove is the best option for heating small rooms. And if such a heating device is equipped with a hob, then it can even cook or reheat food. The stove can run on solid fuel, waste machinery oil, and the simplicity of the design allows to make its own hands.

The types of stoves furnaces ↑

Despite the relative simplicity of the furnace, there are many types of stoves with different design, material, cost and so on. You first need to define the duration of operation of the stove. There are stoves the so-called long burning, and that will be a great solution for the garden, especially if you plan to spend it on the holiday season.

The most popular option are the stove, made of cast iron, but are stainless steel. The design of the stoves is quite simple and represents a bin of metal with the furnace door and the chimney flue. However, there is a furnace with two combustion chambers.

With regard to used for stoves, fuel, the most common are wood-burning oven. The popularity of these models is caused by the fact that firewood is enough available material. But the cheapest option is stove stove running on wood chips and sawdust. Of course, there is a furnace adapted to operate on waste machinery oil, however, their design is the most complex of all the rest.

Cast iron stoves for cottages ↑

Currently, the factory cast-iron stove stoves are available in a wide range and in addition to the basic functions can be a worthy decoration of the interior. Stoves can be heated with wood or any other solid fuels and be used not only for heating but also cooking and also as a hot water boiler.

Modern country stove made of cast iron is able to heat the room with an area of 50-60 m? with standard height ceilings. It may compete with the fireplace or brick oven. In addition, the stove is quite mobile and can easily be moved or transported to any other place. The only negative, cast iron stove the stove can be done with your own hands at home.

Wood stove from a gas cylinder with your hands ↑

Currently, there are lots of drawings of stoves of all kinds. Most options, of course, difficult for perception and self-Assembly, however, let’s consider the most simple and straightforward options.

Oven stove made from a gas cylinder, may be both horizontal and vertical. In any event, before starting work you must make the relevant preparations to eliminate a fire hazard. To do this, you must do the following:

- remove the valve and out of the remains of the gas cylinder;

- flip the container and drain any remaining condensate in a tank or bucket, avoiding contact with the floor;

- to put the tank vertically and fill it with water which will displace the remains of the gas;

- drain the water and the balloon is ready to manufacture the stove.

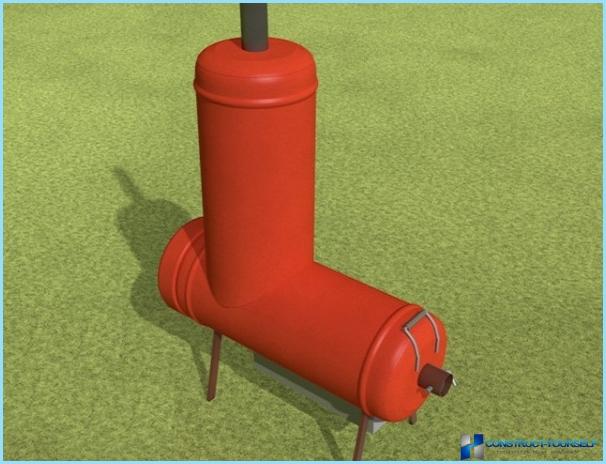

Horizontal option ↑

In some cases, a horizontal version of the stove is preferable, especially if the firebox of the stove will be wood.

The sequence of actions

- the top of the gas cylinder to cut using the grinder;

- fittings cut into pieces of desired lengths for the grate and weld them inside the vessel;

- in the bottom of the container to cut out a rectangular hole which is the entrance into the compartment of the furnace. From waste metal is made the furnace door to which the hinges are welded and fastened to the handle. On the perimeter of the door, it is desirable to paste over asbestos cord;

- at the bottom of the cylinder to make a hole, through which from the furnace chamber be backfilled ash;

- under the holes for receiving ash set steel box with a door;

- from the corner or pipe sections to make the legs and weld them to the cylinder;

- on top of the cylinder to cut a hole and weld in its place a chimney;

- in the upper part of the cylinder it is also possible to weld a metal frame that can be used as a cooking surface.

Vertical stoves ↑

Vertical stoves are good that takes less space. Bake in the manufacture of fairly simple to do this, perform the following steps:

- mark on the cylinder space to the furnace door and ash pan;

- grinder to cut out the marked holes and install made from waste metal doors with hinges and handles;

- 10 inches below the level of the furnace doors install the grate out of rebar;

- to the bottom of the container to weld the legs of a metal bracket or tube;

- from the top or side of the cylinder to make a hole for the chimney to which is welded a metal pipe.

The video shows the whole process of making kiln stove from a gas cylinder.

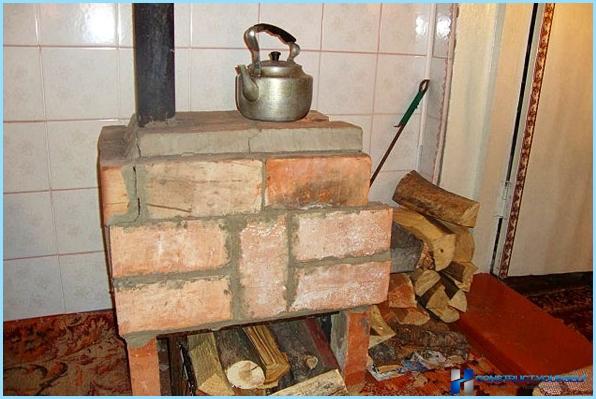

Brick cottage stove ↑

For the main stove casing of rectangular shape should be made from sheet metal with a thickness of 3-4 mm. In the first place are welded to each other side and have them fastened the thick cover, grate and the bottom. The chimney should be made of metal of great thickness. The finished design to impose with a brick.

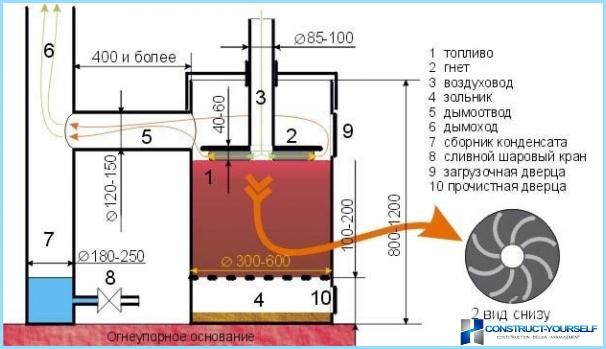

Furnace long burning ↑

Such furnace has a very important advantage, namely, the oven doesn’t require frequent bookmark of fuel. This is achieved through the use of a pyrolysis process. Combustion of fuel occurs in the upper part of the furnace, and the combustion process is replaced by decay. The fuel burn lasts up to 60 hours.

For the manufacture of long burning stoves will require a large diameter pipe or steel barrel and channel.

The process of making

- the bottom of the barrel is cut with a grinder, and edge-aligned and trimmed;

- sheet steel is cut the lid in the center which make a hole under the pipe with a diameter of 100 mm;

- on top of the stove welded pipe for a chimney with a diameter of 150 mm;

- at the bottom of the pipe is welded and strengthen the corners of the circle, which is the measure of fuel burn will fall down;

- under the upper chamber is placed a special divider is slightly smaller with a hole diameter of 10 mm;

- the pipe is mounted in the cover.

How to melt stove ↑

It may seem that kindling stoves is quite simple. However, this is true in the event You at least once faced with furnace heating. If you are a beginner among the firemen, let me offer detailed instructions. So:

- Paper. The grate must be put crumpled paper (can do this with any newspaper).

- Firewood or kindling. Depending on what You have to put an ignition material on top of the paper. It is worth considering that the brushwood, as dry as it was, erupted worse than Lucina.

- Fuel. On brushwood or kindling to lay a few small logs. Whatever fuel You use for stoves, firewood necessary, in any case. Even fuels such as coal, will simply not ignite firewood, as it requires high temperature.

- Ignition and control. After everything is done you can run the furnace. Set fire to the paper, while ash pit wood burning stoves should be half open. Do not forget that the thrust of such stoves is regulated only with the help of blower. It is not recommended to shut it down completely, but it is best to leave a small gap. Strongly do not overload the stove with wood and keep power.

A potbelly stove on the sawdust ↑

Sawdust, of course, is not the best kind of fuel because of their weak combustion. However, due to the easy availability of this fuel this type of stove is also widespread as a wood-burning stove.

The stove design consists of two metal cylinders of different diameter. The cylinder of smaller diameter is inserted in a bigger and is a camera for fuel. In the bottom of the fuel cylinder to cut a hole with a diameter of 50 mm and a strip about 10 mm. the Pipe of the chimney is arranged at the bottom of the outer cylinder. Box for ash is welded from steel of 3 mm thickness and is supplied with door.

In the hole of the inner cylinder is inserted into the core of a conical shape, made of wood and has a height of 500-600 mm. Around the core backfilled and well compacted sawdust. This is to ensure that the combustion was not too intense. Removing the core fuel compartment to install the stove.

The ignition of the sawdust stove is run through the ash box with wood shavings, bark or burning sticks. Fire through the gap will ignite the sawdust and when it reaches the top layer of the stove should cover.

The installation of stoves in the country ↑

When you install in the country or in the home stoves of any type should not forget that the stove body is still metal, and thus heats up pretty quickly and strongly. The steel stove cools faster, and cast iron stoves retain heat for a long time yet and so they must be installed in accordance with the rules of fire safety.

Installation the stove should be on a fireproof base, such as:

- concrete;

- brick pedestal;

- tinplate sheet;

- outdoor ceramic tile.

Absolutely not permissible to install the stove on:

- parquet or wooden floor;

- laminate;

- linoleum;

- carpet or any other soft flooring;

- plastic.

Stove should be on wood panels or walls at a minimum distance of 1 meter. The area of the chimney in the room should be in one piece without any joins. If it is for some reason impossible, then the connection must be performed with entering the lower section at the top. The fuel is placed in the side of the furnace door to possible sparks or accidentally dropped coal will not ignite it.

Conclusion ↑

As You can see, there are many choices of stoves stoves for cottages and garages, and sometimes they can be simply irreplaceable. Such stoves can heat almost any kind of fuel, and even waste. Due to the simplicity of the design and with the appropriate tools and materials to create a furnace in home will not be difficult.