The contents

Depending on what tasks are assigned to the hot water storage tank, oven is selected with a certain volume of the tank. When using only boiling water for scalding stones, warming the broom, it makes no sense to put a large tank.

Variants of installation of the water tank ↑

Depending on the installation, there are several variants of installation of the tank under the water:

- adapter;

- samovar;

- hinged

Adapter placement involves the installation of the tank directly into the combustion chamber. At the samovar version tank mounted on a chimney. Attachments location involves the installation of the tank on the side of the furnace. Sauna stove with water tank may further include a heat exchanger. It is used to ensure a comfortable temperature in the anteroom and terrace. Additionally, the heat exchanger supplies the steam room and shower hot water.

The size of a brick stove used in the bath, influenced by the following factors:

- the area of the steam room;

- the number of people that will use it;

- the seasonality of the use of baths;

- the application

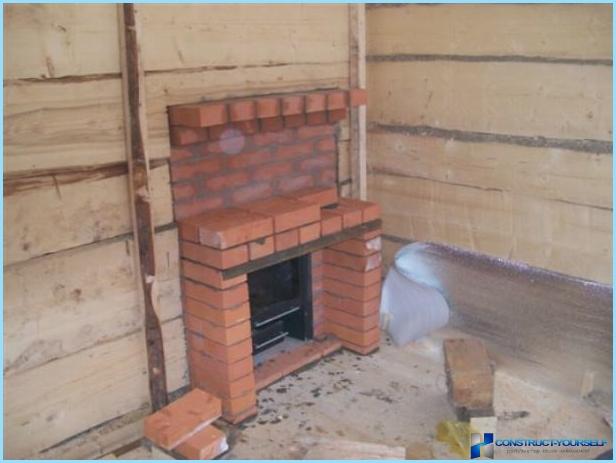

To find a turnkey project of brick, completely satisfied the owner, is quite difficult. In most cases, it is necessary to alter the existing order, to make major changes to the original draft.

When changes in the project changes, consider some of the specific characteristics of brick masonry:

- In heaters the fuel compartment should be of significant size to ensure full combustion of the wood, to guarantee the quality of the flow of air. Ashbox’s door, ash pit itself, also make impressive size.

- To obtain the normal ward air into the furnace, the grate bars are placed parallel to the ash-pit channel.

When the location of the heater above the firebox, the firebox may not be less than see Ideal consider of the furnace bath with the water tank (pictured) with the fuel cell in 8-9 bricks. In this case, stone heating will be uniform. If you reduce the size of the firebox, between the stones will accumulate soot, the temperature in the furnace is reduced.

Masonry ovens ↑

Masonry stoves with the water tank begins with training grounds. Separately preparing a clay-sand mortar. Next, the bricks are laid dry on the plan. First laid the corner bricks are matched in size to the width of joints not exceed 5 mm. Only after this phase is complete, you can start laying the bricks in mortar.

Check the verticality and horizontality is performed after the laying of the range, this will require building level. To assess the quality of corners, use a plumb. Adjustment is necessary even with minimal tolerances, otherwise the oven would be safe, besides the water in it will not be heated to the desired temperature.

There are certain nuances and installing doors. In places where the doors will fit snugly to masonry, first do a layer of layer of asbestos. For locking doors you will need wire or steel cord.

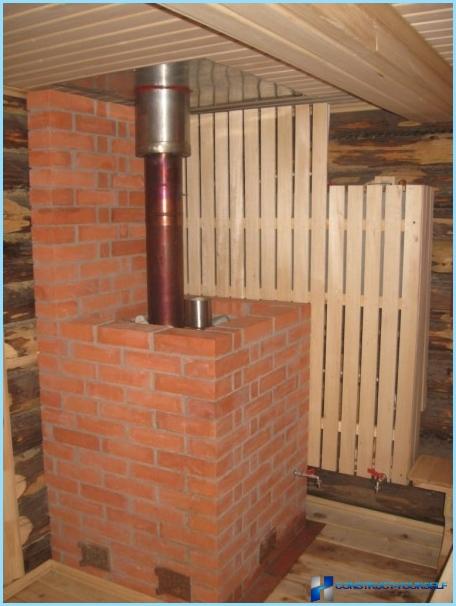

Attention also should be paid to the place where the pipe from brick kilns will pass through the wall, roof, or ceiling. Performed quality pipe insulation with insulating materials, for example, basalt wool.

The video presents the algorithm for creating the stoves of brick

Stoves with water tanks of brick ↑

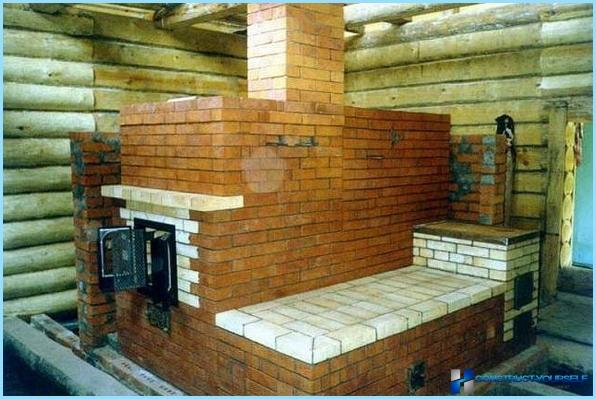

These brick stoves with water tanks are small, they are easy to make. Key elements are:

- tank under water;

- oven-stove;

- chimney;

- support under the tank;

- fire doors and blower;

- the pedestal of the heater grates

For the manufacture of the container under the heater uses a steel thickness of about 8-10 mm. Tank under the water made of pipes with a diameter of 40 cm as a support under the heater you can use a frame made of corners of the 50 by 50 cm To the heater cover is meant for laying stones, sacrifices water.

The heater is placed on the frame, then obkladyvaetsya brick, standing on the edge.

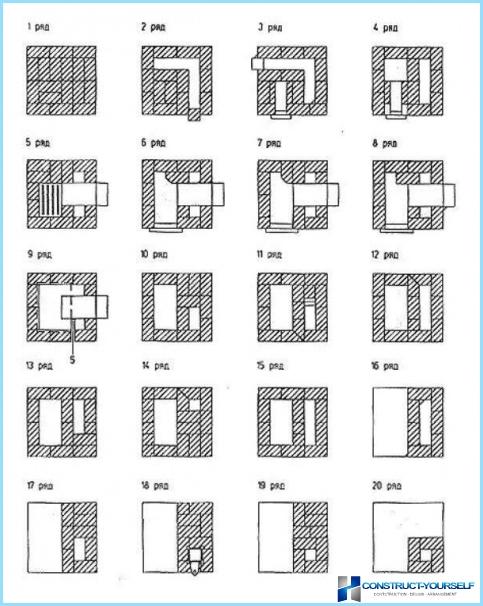

Poradovka furnaces ↑

The lining of the bath furnace with a water tank simple, does not involve significant time costs.

Furnaces are designed for heating steam, in which at the same time is 3-4 people. Loading stones into the heater is carried out after complete drying furnace.

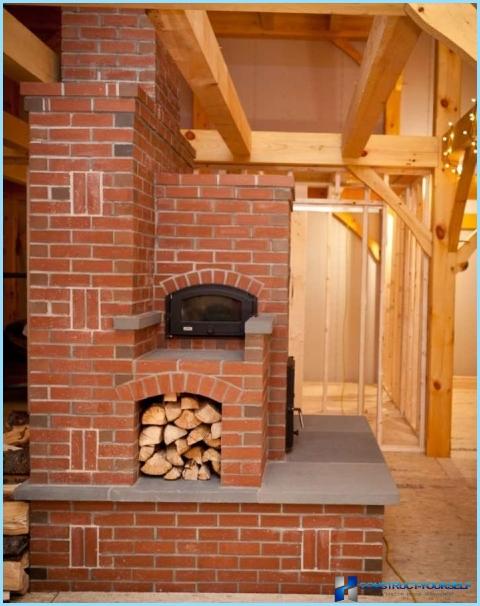

On this oven, will require about 700 bricks, 30 small buckets of sifted sand, 40 pieces of refractory brick 15 buckets of clay for construction. Accessories needed 2 furnace doors, door blower, 2 valves, 2 grates, metal angle 30 30 panel with burner, steel Cabinet under the stones.

This pizza oven is placed with the base (zero) line. In this form the vent. When laying it is important to observe the layout of the bricks, to check the levelness and verticality in each row, to monitor the quality of the corners.

The damper is performed in the third row. Immediately occurs and the formation zolnikov inserts, are placed the furnace doors. The door blew shut in the 5 row. Set the jumpers to create the transition to the furnace. For jumpers use metal not thinner than 3 mm. In the 6 series share mine, using 2 grates grate. Shaft furnace spread fireclay brick, you need a special solution. Styling of the grating, the bricks make a special pit, to 6-10 mm free distance in the case of thermal expansion of the material. Then performed the laying of the flue channels, this would require strip steel.

Fireclay brick 7 number put side attached fire box door. 8 row is facing the doors. Then they are covered with metal strips, serving as support for the brick slabs.

10 a number of furnace doors fully lay bricks, then file (if necessary). Next comes the laying plate, and installing the Cabinet under the stones.

With 12 rows of laying the channels to the chimney, and 15 row lock the door to remove soot. Then attach the chimney the door. With 22 number begin to narrow the fuel in the mine and in the 24 row fully overlap.

To create the chimney, with 27 number of laying only one chimney.

Conclusion ↑

Stone oven with large water tank – the dream of every vacationer. To make a furnace capable of any host, you need to choose the option of the furnace, to seek advice from professional potters to fill your desire and patience. With minimal time and material costs you can expect to receive the desired result.