The contents

- How to prepare the raw material for roof

- About the technology the arrangement of a thatched roof

- The advantages of natural raw materials

- About the merits of the jungle cover

- Technology laying on the roof of reeds

- Rules of operation characteristics of the thatched roof

- Thatched roof with natural clay

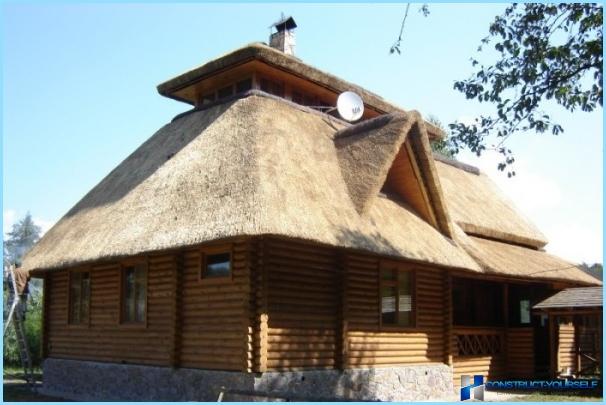

Since ancient times, people used natural materials in the construction of dwellings. Currently, the roof is made of reeds became popular, the reason is eco-friendliness and versatility of this material.

The original roof of straw and reeds suitable for any interior, it can be done with your own hands.

How to prepare the raw material for roof ↑

To harvest reeds for roof needs in the winter. As soon as the ponds covered with solid ice, you can mow the reeds. Further, from the plants put in the sheaves, dry them.

Next, remove the whisk of the cane, leaves, to prevent rotting of the plants.

About the technology the arrangement of a thatched roof ↑

In the construction market presents a variety of types of reeds, you can choose the variant that will appeal to most. Depending on the species of plants used several technologies of manufacturing a roof of reeds with their hands:

- English;

- Danish;

- Dutch;

- Polish;

- American.

To increase the strength of the finished product uses stainless steel wire.

- Dutch technology roofing reed bundles involves packing plants to two meters in length. Stem thickness should not exceed 6 cm.

- In the Danish technology use stems no more than 1 m, the thickness is 4 mm. the Technology is characterized by complexity, significant time spent.

- Polish technology to the roofing with reeds involves the creation of a loose structure, spikelets loosely applied to each other. This roof is made of reeds suitable for gazebos.

There is a division of the roofs of reeds with their hands on two groups:

- open;

- closed.

In the case of the construction of the coating on open technology, the bundles are placed in a special crate so that the inner surface is served in the room ceiling. This method is used in the construction of bars, cafes, restaurants.

The disadvantages of the method:

- the complexity of the construction works;

- high cost;

- estetichnost (lint from the cane will fall into the plates of visitors).

The closed technique involves creating a wooden structure to which attached plants.

Advantages:

- reasonable cost;

- aesthetic appearance;

- excellent waterproofing;

- minor and temporary labor costs.

The advantages of natural raw materials ↑

This material has many positive characteristics, it is easy and convenient to operate:

- the resistance to putrefaction;

- resistance to high humidity;

- excellent sound insulation characteristics;

- excellent waterproofing;

- the lack of allergens.

For arrangement of the roof are not suitable plants that develop in salt water.

About the merits of the jungle cover ↑

This roof is not afraid of temperature extremes, high humidity.

The surface formed by the fungus, the roof is rotting, because the natural plant in natural conditions grows in a wet environment.

Reed roofing system has natural ventilation, will not require additional arrangement of heat-insulating materials.

The tubular structure of the stems of reeds contributes to the reliable protection of the roof space from outside external noise. The operational life for a thatched roof is 50-60 years.

In addition to the aesthetic benefits will also celebrate the uniqueness of this coating is its sophistication.

After installation, natural roof has a Golden color, gradually increasing its intensity. The facade of the house, house territory is complemented by the natural colors, significantly improved the General perception of the house.

Technology laying on the roof of reeds ↑

1 way. This technique involves laying the reed bundles of the rows. First, do the eaves. On the roof of the plant is placed the same way as it was growing in natural conditions: whisk up, root down.

2 way. The bottom row includes down by the roots, subsequent series are arranged so that the root of the plant facing up.

3 way. Material throw on the roof randomly, press cargo (wooden poles).

In modern construction give preference to the first method of arrangement of the thatched roof. In the ranks of the plant is pierced with the steel wire, is fixed with screws to the crate. When all the sheaves laid on the roof, they are carefully «comb», spread with forks and blades.

The roof of reeds, stacked without faults, has a velvety and monolithic appearance. When parallel stacking sheaves between them, no air gap, the roof will be fireproof.

For formation ridge of the roof boards are used, Heather branches, or inverted sheaves of reeds stacked «pairs». Dutch ridge thatched roof used natural tile. The roof is further coated wire mesh, preventing netdania on the roof of the birds.

Rules of operation features thatched roof ↑

- A year after the construction, the roof must be corrected, re-seal, then brush with brushes.

- For reeds allowed roof pitch of about 30 -35 degrees. The thickness of this coating is 30-35 centimeters. Per square meter of roof maximum load 35 kg.

- The crate under natural material make durable, not solid. The classical variant of the gutters to the roof will not fit under eaves overhang attach system, linear drainage, drainage perform in the storm drain.

- Mnogoschiptsovye and hipped roof made of natural reeds assume the same thickness main beams and ribs. Such coatings having smooth transitions, mainly performing in the form of a conical and tent structures.

- The roof under the trees have systematically cleaned from twigs and leaves to prevent growth of other plants reeds.

Thatched roof with natural clay ↑

Crate perform solid, bundles of plants are placed in neat layers, with roots in the ground. At reed, located at 10 cm, placed on top of dry soil (2-3 cm), and rams. Next, coat the soil with a mixture of clay and straw cleavers.

The flow of such mixture is:

- 10 g of cane;

- 4 g of broken rice straw;

- 40 cm3 of earth and clay.

Styling clay and reeds allowed for roofs with slope up to 40 degrees in the following technologies:

- Soaked for 7-8 days reeds in a clay solution. Performing at the roof line type of the sheathing, the spacing between slats is 35-40 cm.

- Steeped vegetable bundles have vertical rows. To cover a square meter of such a roof will need 20 g of cane and 30 cm3 of a mixture of clay.

In modern construction give preference to the tile, proplist, slate, forgetting about this amazing and ancient natural raw materials. And it was reed roof guarantees a unique and original design, is safe for a man material.