The contents

- What and where is burning in the oven

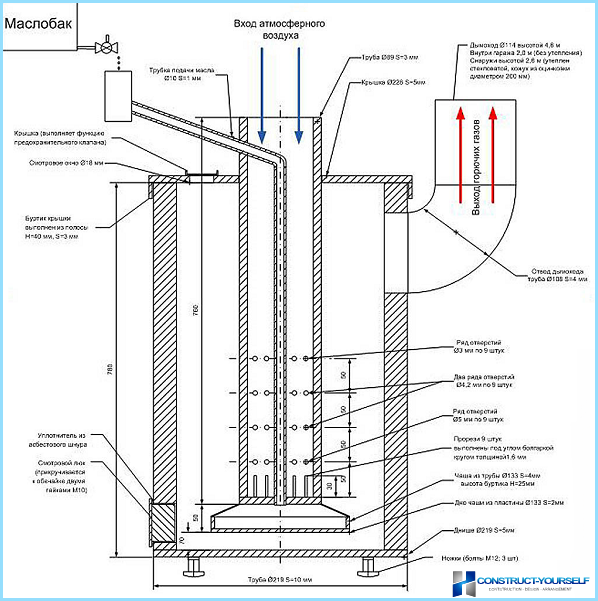

- Option drip furnace

- How to organize a competent heat removal from the surface of the furnace

Among the many variants of improvised heaters and stoves is worth to mention an interesting design of the heater furnace waste oil. Many old car enthusiasts in garages and basements keep a considerable amount of used motor oil. In the work for its intended purpose, the lubricant is not necessary, and as fuel for stoves on community service fits.

Options furnace waste oil ↑

Appearance of furnace oil does not cause enthusiasm, but it is only at first glance. Almost all the homemade versions of the furnace on waste grease repeatedly improved and altered in order to achieve stable operation and good heat transfer. To understand and assess the reliability of the design, it failed to make a furnace in working out with their hands, or use a ready option in the bitter cold.

This files most often made for yourself the most simple and easy option furnace on waste oil. If desired, you can assemble more complex structures:

- Oven on testing with the supercharged air into the combustion chamber;

- Bath furnace waste oil with adjustable heating power;

- Oven on working out with the water system or forced air cooling of the heated surface;

- Drip furnace waste oil.

For most designs you will need a black sheet metal with thickness 3-4mm, angle grinder with three discs for metal, welding machine electrodes and tens of No. 4.

The structure and operation ↑

For the operation of the furnace any suitable hydrocarbon oil, the consistency and properties similar to motor. Can be used hydraulic and ballast fluid, all that can burn in a highly heated condition. Separate people manage to burn rancid vegetable oil, and even molten grease waste grease.

What and where is burning in the oven ↑

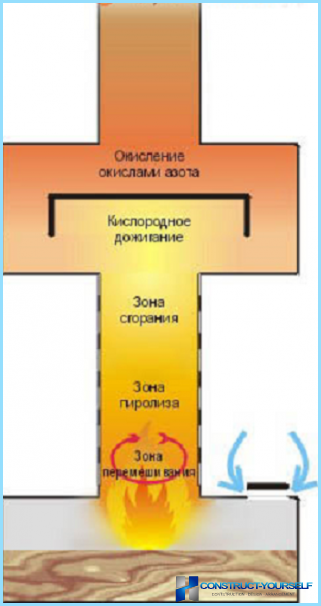

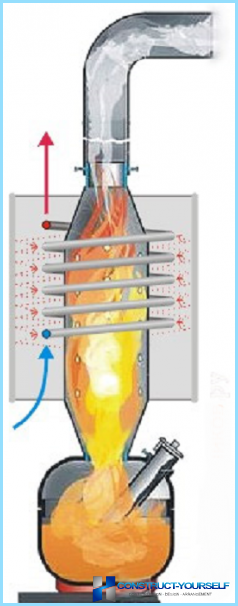

The design of the stove waste oil has two main areas of combustion and one auxiliary. As such, a separate front or flame of burning fuel-air mixture in the furnace no. Conditional area burning is in the combustion chamber – perforated pipe connecting upper and lower part of the furnace.

In the lower chamber is a supply of waste oil, the less its volume, the faster and better heated waste oil, the faster it evaporates and burns. To the lower reservoir via a metal duct connected for additional capacity or tank with the main supply mining.

The most difficult process of firing the furnace. For this purpose, the combustion chamber pushes a few pieces of oakum, saturated with kerosene. In the lower capacity of the furnace through the hole with a lid pour exercise ¾ the nominal volume. Set fire to the oakum, and the process of firing went.

As the warm oil starts to evaporate rapidly, pairs, mingling with the heated air entering the chamber and increase the combustion. Under the action of the thrust of air in the pipe, the combustion products are quickly removed to a safe distance.

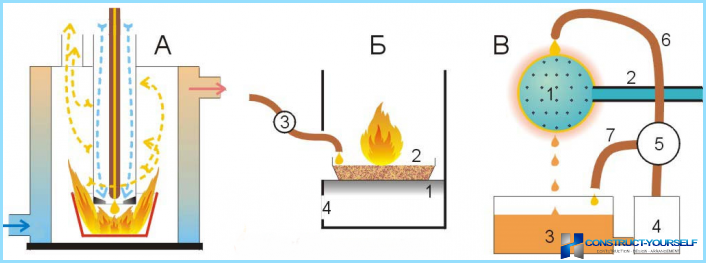

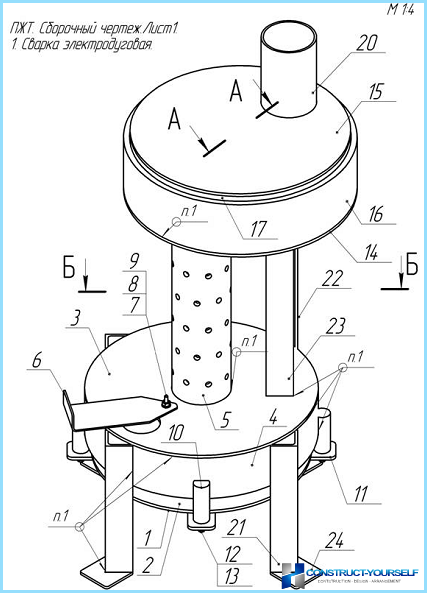

Option drip furnaces ↑

In addition to the above variant of the furnace working out, like a giant dumbbell, set vertically, there is another very interesting diagram of the furnace on the motor oil. This design is also called a stove flame Cup. The principle of operation is clear from the drawing furnace on community service.

At the bottom of the cylinder is open the small container, with a filler in the form of a broken wire potency. On a vertical the top tube flows down and drips testing. Drops waste oil falling on hot metal, evaporate with the decomposition of heavy petroleum products into lighter components. They really burn well and produce less soot.

The heat from the cloud of burning oil is transferred through the walls to the surrounding air or in the body of water tank or heat exchanger.

If the issue is not about the mobility of the furnace working out, it is better to use a design with drip oil feed.

How to organize a competent heat removal from the surface of the kiln ↑

Create burning ball of fire a little. It is necessary still as-that correctly to remove the heat into the surrounding space and warm the air in the room. In fact, it is the oil counterpart of the stove, near the heat, and a little distance cold.

Here in the furnace waste oil manifested certain drawbacks, which need to know and be ready to deal with the possible consequences:

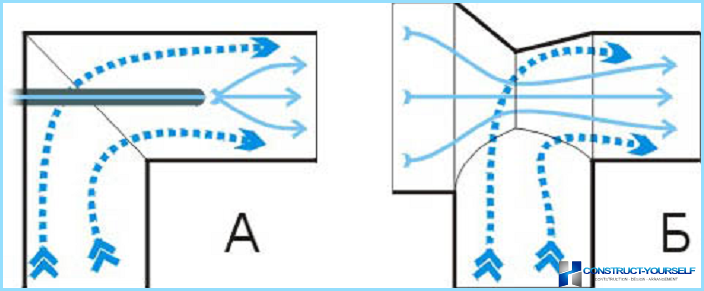

- High temperature combustion chambers, oil intensely dry air in the room, «eats» oxygen and fills the air with a variety of dangerous compounds unburned oil. To eliminate the latter factor use oven for testing with a boost. With the help of electric fan through an additional nozzle at the junction of the upper container chimney serving the air. This upgrade pumps the leaked combustion products from the premises, improves ignition and cravings, often allows to reduce the height of the chimney up to 2.5 m.

- Ring furnace design on the testing tied to the location of the pipe exhaust gases, a large part of the surface, radiant heat is not directed toward the center of the room and the walls. Therefore, to increase the efficiency of heat transfer is usually used reflective screen of glued aluminum foil material.

- It often happens that the heat have not only a corner in the garage or shed, furnace testing with a water circuit enables you to heat the whole house under 100mTwo. Usually copper heat exchanger with water soldered to the upper chamber of the furnace. But the best solution is recognized as the scheme specified in figure.

Design and assemble the oven on working out their own ↑

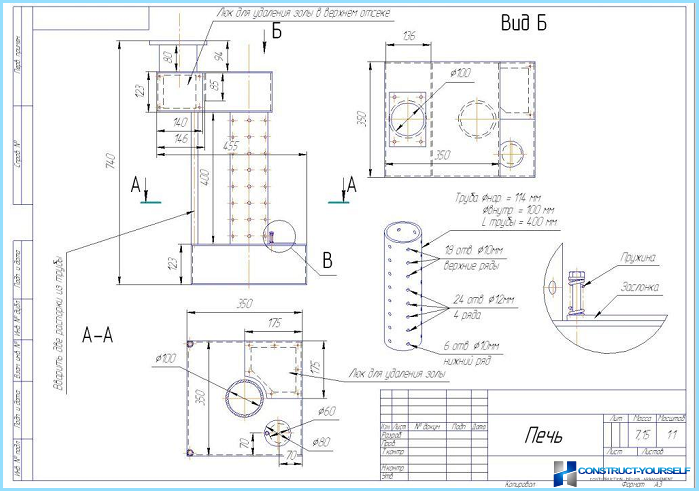

The production design is very simple, the first phase of the cut blanks from sheet metal according to the drawing, the second phase qualitatively weld by electric welding in the finished structure in accordance with the scheme.

Step one – make the main parts ↑

First cut out the sheet and cut grinder 4 bottoms of the upper and lower chambers of the furnace. For final machining to leave a seam allowance of 1mm and diameter of each object. The cut of the workpiece driven by the size of the drawing on the trodden. The same requirement applies to the side walls of the chambers.

For the flame bolt you can use a thick-walled pipe or an old cylinder with a wall thickness not less than 4mm. With core mark up the hole positions and drilled them on a drill press can drill.

Step two – Assembly design ↑

Welding work is straightforward with the correct selection of the welding mode.

Further work performed in the following order:

- We catch the points of the bottom and side walls of the lower chamber, proverjaem seam twice to get firm and tight connection;

- Set a flame chamber in the finished lower chamber and fix one point, heat with a blowtorch to the place of laying of the weld and also hot proverjaem twice;

- Put on the tube bottom the bottom of the upper chamber and weld similar to the previous paragraph;

- Weld the side walls and the lid of the top chamber, the support adapter to the chimney in normal mode.

For the filler hole of the stove pick up the option easy removable tight cap or shutter to regulate the amount of air sucked by the stove.

Test ↑

To check the reliability of the connection should conduct thermal testing of the furnace. The goal is to check the reliability of welds under the action of internal strains in a heated condition. You can install two or three operating blowtorch in the direction of the flame chamber and warm the design in half an hour. If the design will not lose any of the welding seam as the product is ready to use.

Summary ↑

Furnace waste oil makes sense only if you have the opportunity to purchase or barter for testing in sufficient quantity for little money. In modern conditions of the market to collect free 100-200L of fuel at a time is feasible, but for continuous use the required source in order more powerful. So the furnace is on working out the economic problems can be more complicated technical.