The contents

The range of possibilities for the organization of heating in a private house at the moment is quite wide. In a situation when the installation of the electrical equipment is not supported by financial capability and a gas pipeline nearby is missing, come to the aid of a diesel boiler. The regular upgrade of technical characteristics allows to choose the design most suitable for a particular situation.

The advantages and disadvantages of installing a diesel boiler ↑

In addition to heating, the acquisition of dual circuit units will provide tenants with hot water. The solution set for heating of private housing diesel boiler has a lot of arguments:

- The capacity of the unit allows you to effectively heat the large space of a private home.

- The diesel boiler is characterized by high efficiency, which varies in the range of 91-95%.

- The availability and low relative electric source, the cost of fuel used.

- The no need to obtain permits for heating diesel boiler.

- Adjustable temperature mode.

- The presence of the control system, controlling the set parameters, easy operation.

- Automatic control facilitates compliance with fire safety regulations.

Any equipment for heating of private housing has a number of drawbacks. Among the difficulties faced when buying a diesel boiler, note the following points:

- The unit is running on liquid fuel, installed in a separate building, equipped with high-quality ventilation, extractor fan and window. Room height must not be less than 2 meters, the walls are made of non-combustible materials.

- Storage of diesel fuel, care should be taken about the availability of special containers made of steel or plastic. Installation is performed in an isolated room, the connection with the boiler should have a separate pipe. ?Comment! The tank is recommended to bury in the ground. Recommended volume capacity – from 4 to 10 t

- Heating of the private house building diesel boiler is accompanied by a high level of noise. This is another argument to isolate the unit in a separate building.

- Liquid fuel boiler is partially depends on the availability of energy supply, interruptions in the heating process will stop.

- The difficulties caused by the properties of the fuel to thicken at temperatures below +5onC. This complicates the movement of the heat carrier in the heating system. Also there is the possibility of clogging of the filters and the deterioration of the combustion process in the burner. To prevent negative effects of the able insulation of filters and tubing or organization of their heating. The building that houses a container of fuel, preferably equipped with heating.

Operation of the diesel boiler is accompanied by soot formation. When forming a 2 mm layer, the fuel consumption increases by 8%. Timely removal of dirt (once a year) will allow you to avoid unnecessary expenses for heating of private housing.

The principle of operation of the equipment ↑

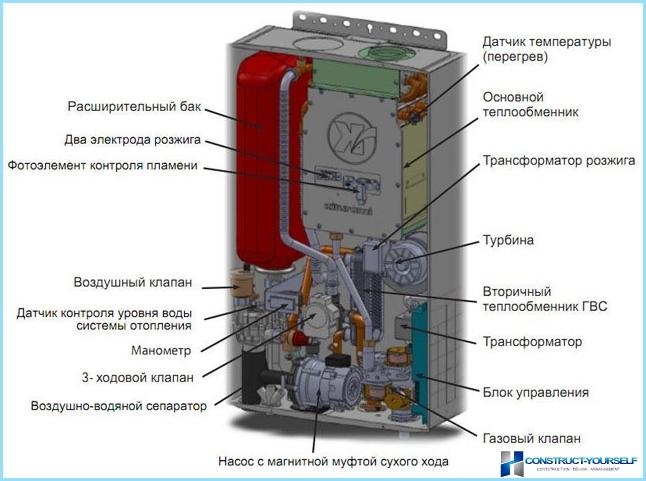

The basic principle of operation of a diesel boiler consists of the following items:

- Start of work the equipment is accompanied by the start the pump and Assembly of the supercharged air.

- The injector is formed by a pressure best suited to the atomization of the diesel fuel.

- Transformer fuse performs the function of energizing the ignition electrodes.

- Diesel fuel in the boiler is ignited, and the heating device goes into offline mode.

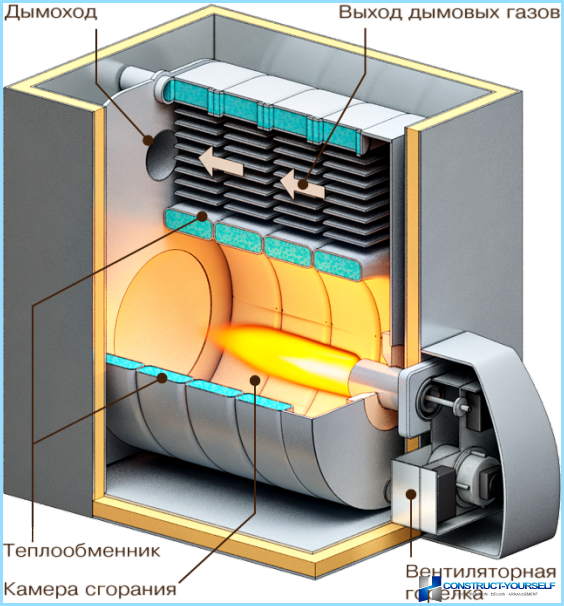

In General, the principle of operation of diesel equipment similar to gas outdoor boilers. The key difference is the burner, which is equipped with a fan or has naduvnye design. In this case, the injected air promotes the formation inside the burner of the desired volume of oxygen for complete combustion of the fuel.

From the point of view of economical fuel consumption, the burners are divided into 3 groups:

- The cheapest and most ineffective are single-stage models. Their characteristic difference – continuous operation. To reduce the temperature in the heating system requires shutdown of the diesel boiler.

- Two-stage designs operate in two modes: 40 and 100 % of its performance. Their installation on diesel boiler slightly contributes to savings in fuel consumption for heating of private houses.

- Modulated burners are among the most economical structures. They are able to adjust their performance from 10% to a maximum power based on the temperature of the room and outside the window.

Technical characteristics of the burner includes the important parameter is the suction depth. When burying tanks for storage of fuel in the ground, choose a design with a high depth suction. Installation of suspended tanks allows you to purchase equipment with less options.

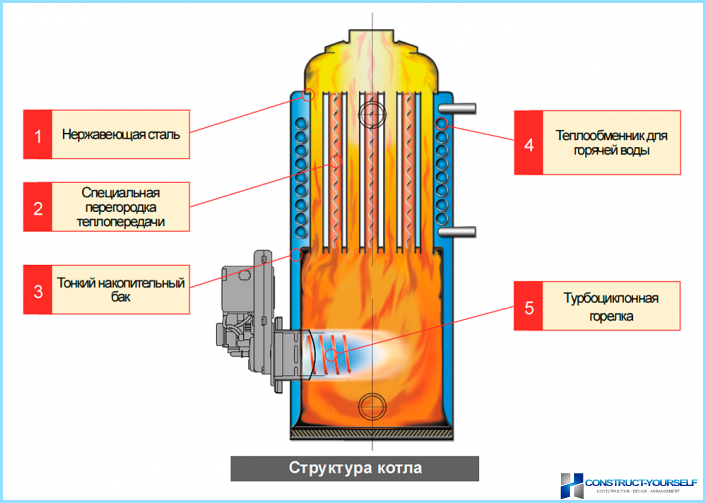

The next important element of the diesel boiler is a heat exchanger which is made of steel or cast iron. Cast iron heat exchanger is characterized by thicker walls, resulting in less subject to corrosion due to condensation formation.

Manufacturers say about half a century of use of such designs, however, you should pay attention to its substantial weight and susceptibility to local overheating. When poor-quality coolant the probability of failure of a cast iron heat exchanger high, it leads to unplanned repair of diesel boiler.

Steel aggregates at low temperatures provoke the coolant in the combustion chamber the effect of acid rain. This leads to corrosion of the walls of the equipment for heating and early failure. Also, condensation leads to an increase in the consumption of diesel fuel. Typically, these systems are used in industrial buildings and not used for heating private houses.

Diesel boilers are made exclusively in the outdoor version, the design cannot be fixed on the wall. To extend the operation of the equipment will allow the use of high-quality diesel fuel, which can be diluted with kerosene.

Fuel consumption ↑

A natural question that arises when choosing a diesel boiler heating, is the fuel consumption. To calculate the desired value is possible, starting from the relationship: the consumption of 1 kg of fuel per hour provides a heat output of 10 kW. For example, consider a private house with area of 150 mTwo, for its heat will need to install a boiler with a capacity of 15 kW. When working at full capacity, the diesel fuel consumption will be 1.5 kg/h during the day the consumption of a diesel boiler fuel is calculated by a simple action: 24х1,5=36 kg, depending on region, private house needs heating at full power an average of 120 days and 90 days in half strength. Means 120х36+90х18=5940 kg, i.e. almost 6 tons.

Calculations are approximate, but when you buy the boiler on diesel fuel it is better to opt for modern models with automatic modes and ensuring economical consumption of diesel fuel. In addition to reducing fuel consumption thanks to the modern design of the unit, sound insulation of private homes is an important aspect of the heating issue.

Review trademark ↑

The choice of diesel boilers intended for heating of private houses is quite extensive. In the study of the range, focus on proven brands and certificates issued by Rosgosstraha and confirming quality of production. Deserved popular following units:

- Korean equipment brands «Saturn» characterized by prolonged period of operation and high performance.

- Another Korean representative firm Kiturami. Its dual diesel boilers provide high-quality heating and heating water for household needs. Equipment TurboChannel burner reduces fuel consumption. Temperature controls suggests 7 modes.

- German units Budurus going high-tech equipment. The quality, attractiveness and efficiency – main features of these diesel boilers.

- If you wish to become the owner of high-power equipment should pay attention to the Italian Ferroli boilers, whose lineup varies from 23 units up to 3500 kW.

Choosing the right model diesel boiler provides sufficient heating of private homes with the simultaneous supply of hot water, the equipment does not need complex care and in compliance with the performance requirements is able to last for a long period.