The contents

- Wooden base

- Installation on the hillside

- Brick base

- Concrete Foundation

- The Foundation for the house from foam blocks

Determination of the need to erect poles ↑

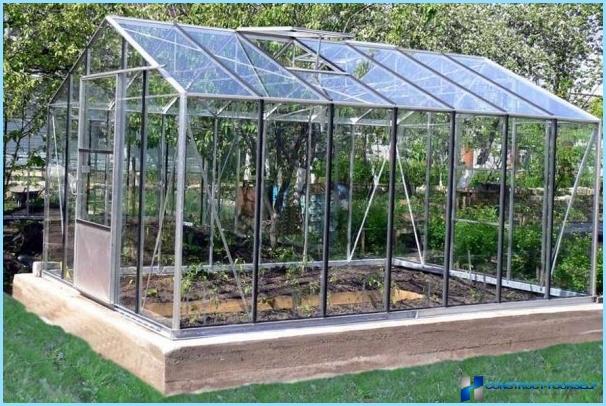

Before you decide on the method of manufacture, should determine whether the Foundation for the greenhouse, because the hard frame of the structure and mutual fastening elements, along with a fairly high mass allow to install it directly on the ground or lining the beds without fear that the structure will get blown away due to the high sail. The high ground in this case, you should say when you apply the glazing frames designs or as stiffeners applied metal profiled elements (area, square, tube), that is, when using materials with high density and mass.

If the greenhouse is finished with polycarbonate, which is characterized by a low density of material and the total weight of the design, a large area of the lateral surfaces and, consequently, high windage is able to provoke the displacement of structure under strong wind. On the other hand, the lack of a rigid Foundation under a greenhouse allows you to move the design across the site, choosing the most appropriate for her location depending on cultivated crops and weather conditions.

The answer to the question: «Do I need a Foundation under a greenhouse made of polycarbonate or other material with the performance?», be positive in the following cases:

- if you are abutting to a building, and planned year-round operation;

- when installing on a country site that is visited periodically and is not guarded, as anti-vandal measures;

- if the depth below the ground freezing to create the climate necessary to grow crops year-round;

- at larger sizes, in order to give rigidity;

- if the site is characterized by low groundwater levels.

- in the manufacture of wooden frames and stiffeners, as a measure to protect the material from rotting in contact with the soil;

- if the installation of a greenhouse constructions produced on the slope.

In order to answer the questions: «What Foundation is best for polycarbonate greenhouses?» and «What kind of Foundation is needed for polycarbonate greenhouses?» you should consider what types of bases are there.

Varieties of greenhouse grounds ↑

As the support base for the greenhouse, regardless of its material and design can be used structures of timber, or sleepers, brick or stone, concrete blocks or reinforced concrete. Each material has its advantages and disadvantages, and the technology of their construction specific. The classification presented below also provides answers to the question: «How to make the Foundation under a greenhouse made of polycarbonate?» and «What should be the Foundation under a greenhouse made of polycarbonate», due to the lack of differences in device and technology development of Foundation depending on the material of the structure itself.

Wooden base ↑

Among all the structural materials used in the construction of bases, the most affordable, accessible and tractable is wood. Given the requirement of massiveness as elements to the wooden base, decided to use the timber or sleeper.

The Foundation for the greenhouses of beam, as well as of sleepers can be accomplished with the installation of soil or the depth below the surface.

The Foundation under a greenhouse made of timber with his own hands with the installation of ground runs on the following technology:

- is the preparation and leveling the surface – it is necessary to remove the topsoil and perform the filling with sand, sand and gravel or fine crushed stone;

- the layout of the perimeter of the base by means of pegs and strings, with alignment angles;

- the timber is pre-organized – treated hydrophobic composition (waste oil), in order to prevent premature rot and fungal attack and mold;

- prepares (cut to size and washed down half of the section) and Assembly of the elements by means of brackets or ties at the place of installation. The connection elements are in series in the cross section of the belt and between the belt.

How to make surface wood Foundation for a greenhouse, you can see in the video, which is presented below:

The construction of Foundation under a greenhouse made of timber when buried method has the following technology how to make the Foundation for the greenhouse:

- Original label to determine the location of trenches, with the adjustment of perpendicularity.

- You are fetching the fertile soil and sandy clay layer to a depth bookmarks base elements (200 – 300 mm) and a width greater than the thickness of the beams 100 – 200 mm.

- Is the crust of the bottom of the trench with sand, ice or dropout, the layer is evenly distributed and compacted, check the horizon.

- Laying of waterproofing material (roofing material) around the perimeter of the trench with the departure of 50 – 100 mm above the surface level.

- Outside of the trenches is made by the enlarged Assembly of structural elements up to height of the surface.

- Installing collected items in the trench and connected to each other.

- The roofing material is tensioned at the perimeter of the structure and is mounted in the upper section by means of staples.

- Sinus between the waterproofing layer and the ground are filled with the previously selected soil, sand, ice or dropout and trebuutsya as backfill.

Ease of handling and Assembly of wooden elements allows to make a Foundation for the greenhouse with their hands. The installation of greenhouses on the Foundation and consolidation of the bias and to give rigidity in wooden base also is simple and requires no fixings.

The lack of stability of the wood to rot it is possible to compensate for pre-installation of dot supports a variety of material options. In this concrete support can be recessed and mounted on the ground.

The installation on the slope ↑

The Foundation for the greenhouse on uneven terrain includes screw piles, screwed into the soil below the depth of freezing, to avoid seasonal extruding, and put on him a belt stiffness of wood or obtained by continuous casting in the mold.

If you have two or three assistants and a lever of sufficient length to set the Foundation for the greenhouse with their hands possible and on the hillside. Screw piles are pipe with screw on end, which ensures the mounting at the desired depth.

The brick ground ↑

The Foundation for the greenhouses of brick is also quite simple to manufacture and has a similar production technology works with the device support structure of the beam in the depth of it below the surface level. The device is a brick strip Foundation under greenhouse, it is necessary to perform the work according to PP.1 – 4 technologies of arrangement of the beam in the underground way, then you must perform the following operations:

- to implement masonry in a half-brick to bring the wall above ground level at 150 – 200 mm;

- after setting masonry mortar to produce the plaster recessed part of the base liquid hydrophobic compound (bitumen) and use the sticker waterproofing material (roofing);

- to fill the sinus between the base and the soil, seal the filling.

Concrete base ↑

The Foundation under a greenhouse made of concrete is the most durable and reliable way to arrange the Foundation, and reinforcement with metal frame gives it great strength and finds application not only as the Foundation for a polycarbonate greenhouses, featuring lightweight, but also for structures made of metal profiles and glass covers.

Strip Foundation for greenhouses of reinforced concrete follows the same technology as the embedded Foundation other tangible performance, but has its own specific features:

- the trench width is determined by the maximum outer dimension of the formwork, with an allowance of 150 – 200 mm;

- formwork can be made of wood, plastic or metal boards with smooth surface;

- laying waterproofing layer is beneath the mold, while the width is necessary sheet is defined as the sum of the base width and twice its height;

- between the walls of the formwork, installed reinforcing elements are connected by welding, wire or plastic clamps;

- reinforcement must have at least two vertical uprights and two horizontal flanges, the distance between the vertical uprights is 300 – 400 mm, and between horizontal zones – 150 – 200 mm;

- for mounting it is necessary to provide fixings for direct connection or with a wooden belt from Board or beam;

The Foundation for the house from foam blocks ↑

Material having high waterproofing performance and therefore does not require laying additional waterproofing layer is a porous concrete, a brilliant representative of which are considered the blocks of foam.

How to make a Foundation for the greenhouse with his own hands, using foam blocks is described below:

- pulled the trench width exceeds the block size of 150 – 200 mm, the base is aligned and is laying on the bottom of the moisture barrier (roofing felt);

- the first layer of foam blocks fixed to the surface with mortar sand-cement mortar and aligned on the level;

- voids in the blocks filled with sand-cement mortar and compacted;

- on a layer of masonry mortar is laying the subsequent layers of blocks;

- sealing of joints is done after drying of the mortar mixes.

The greenhouse of window frames without Foundation ^ the

This method is economical in that case, if in the presence of a large number of old window frames that are a pity to throw away.

The device support member in this case is not mandatory, you can frame the beds of the Board thickness of 40 mm to the width of their overlap two window frames when laying on the ridge. Next is the vertical installation of the frames and their attachment to the framing and each other to give the structure rigidity. After Assembly perimeter are installing Gables and ridges, on which are placed frames, pasted together and to the side walls.

The rationale for the construction of the supporting part ↑

What is the best Foundation for greenhouses to choose is determined by its design features, the heavier and larger the design, the more thorough should be its support. From these considerations you can perform the following breakdown:

- the Foundation of the timber will ensure the weight characteristics of the grounds and greenhouse design with its small size;

- the Foundation of brick is required when a sufficiently large area of the side surface, and for greenhouses boards and films will be justified;

- a concrete Foundation is justified if the size of the greenhouse is very large, and to operate its plan throughout the year. At the same time the concrete Foundation for greenhouses of metal profiles and glass is not a luxury but an absolute necessity;

- the Foundation of foam blocks is justified with the high water content of the soil and of the need to isolate the crops from waterlogging, to prevent rotting, as well as any other material design greenhouse design.

Provides a breakdown allows to make a conclusion about which is better the Foundation under a greenhouse made of polycarbonate.

The Foundation for a polycarbonate greenhouses ↑

What should be the material Foundation for the production of polycarbonate greenhouses is determined by its size, properties of soil and mode of use.

Technology of the Foundation with his own hands is no different from the previously discussed, depending on the material design foundations of design.

Installing polycarbonate greenhouses on the Foundation is to consolidate the design to the base using standard fasteners. The Foundation under a greenhouse made of polycarbonate regardless of what he’s done should be covered with wooden beam or Board in order to avoid any question about how to install greenhouse polycarbonate on the Foundation.

Video of how to install a polycarbonate greenhouses on the Foundation described below:

The answer to the question «How to put greenhouse polycarbonate without Foundation?» simple – it is necessary to level the surface on which you are installing, set design and fasten with pins to the ground. If the soil is loose and the length of the regular pins are not enough, they can be replaced with a longer.