The contents

- Under what types of furnaces can not equip foundations

- How to determine the weight of a brick oven

- Basic principles of the structure Foundation under the stove in the bath

- The signs of a poor Foundation

- Varieties of Foundation

- Monolithic

- Monolithic slab on stilts

- Block

- Rubble concrete

- Tape

- Columnar

- The Foundation on screw piles

For a solid base of the furnace in the house or bath normally requires Foundation. It will serve as a support to evenly distribute weight load and significantly increase the service life of the furnace. In addition, a Foundation under the stove in the bath protects the lower part of the structure from the effects of moisture and serve as insulation between the warm stove and the cold ground.

Under what types of furnaces can not equip foundations ↑

Mostly this includes stoves, made of metal. They are of two kinds: wood and stoves.

Small brick ovens can also be light in weight. To determine their mass it is possible to use simple calculations. But usually the weight of the heater reaches 1.2-1.5 ton.

On average, the weight of a standard furnace ranges from 6 to 10 tons. Therefore, the device of the Foundation for the Russian oven under classic street kiln is absolutely necessary.

How to determine the weight of brick kilns ↑

Weight is determined by the number of bricks and the weight of one brick. To simplify the calculations, the weight of the stove can be defined in one of several ways.

- Standard chimney brick weighs 4 kg. by Counting the number of bricks going to build a furnace, you can calculate the final weight.

- Red brick weighs 3.5 kg.

- Weight of masonry can be calculated by multiplying the total volume of masonry (meters) 1350.

Basic principles of the structure Foundation under the stove to the bath ^ the

Typically, the Foundation under the oven in the house poured at the same time with the basic Foundation and at the same depth.

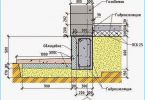

The Foundation of the furnace is necessarily arranged separately from the Foundation walls, it will provide him a free draught. Minimum distance from wall is 50 cm In this case leaving a free space from 3 to 5 cm between the base of the furnace in the bathhouse and base of the wall and covered it with sand and lay on two sides waterproofing material.

The size is determined based on the length and width (must not exceed the dimensions of the furnace at 6 – 10 cm at each side). The depth of the Foundation under the stove depends on the geological data of the site.

The chimney creates a major load on the base. It should be located as close as possible to the center of the Foundation. Also in the regeneration furnace to calculate the pipe axis and the location of load-bearing structures of the house (beams, rafters), to avoid overlap. Under the powerful chimneys sometimes construct an independent basis. Regardless of the type of slab or piles, the weight distribution of the furnace at the base should be made evenly, otherwise the design will fall apart.

The signs of a poor Foundation ↑

If in the process of installation of foundations under the stove in the bath mistakes or he is not strong enough, the furnace will be subjected to the following deformations:

- partially destroyed walls,

- cracked case «through»,

- the destruction of the chimney.

The most unpleasant that all these defects are not subject to partial repair. As the reason Foundation, restored the oven will be exposed to a secondary destruction. In the event of such characteristics will have to completely disassemble the figure and mount the stove again.

Varieties of Foundation ↑

In principle the device of the bases are divided into monolithic and columnar. The first represent a whole plate made of various materials: crushed stone, concrete, concrete slab, burnt brick. A type of such reason is a continuous footing. The second type is based on columns or piles. Piles can be a screw.

Monolithic ↑

Monolithic slab on stilts ↑

The same solid foundations, only strengthened from the bottom bar or screw piles. Applies to insufficiently stable soils.

Block ↑

This base is mounted of concrete or steel blocks, strapped with wire and filled in with cement mortar. When correctly stacking blocks the design is quite robust and does not require a lot of time.

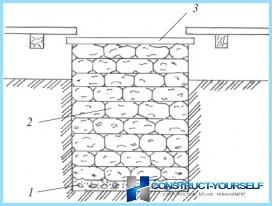

Rubble concrete ↑

Consists of large stones on a sand cushion, filled with cement mortar. Suitable to construct lightweight stoves-stoves.

Tape ↑

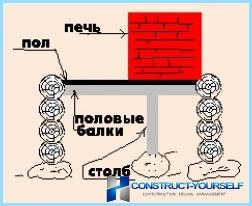

Columnar ↑

The Foundation on screw piles, ↑

How to choose the Foundation depending on the soil characteristics ↑

The depth and type of Foundation directly depends on three factors:

- the depth of soil freezing,

- soil type,

- the height of the aquifer.

This data is obtained through geological exploration. Specialists drilled wells, perform soil sampling and determine the necessary construction parameters. This procedure is about 2500 thousand rubles. Of course, you can decide and «to the eye», but in this case there is a danger not to guess. But the mistakes made in the construction of foundations is expensive.

On heavy clay and loamy soils with shallow aquifer used pile Foundation. Piles installed to a depth of soil freezing. As an interim solution in such cases is sometimes used finely recessed slab on piles.

When groundwater comes close to the surface, and the soil not susceptible to the swelling, but has a weak bearing capacity, it makes sense to bookmark in the form of concrete slabs or rubble concrete Foundation.

On sandy and dry soils the Foundation operate on the depth of frost penetration (it is not more than 60-80 cm). But mostly in the middle zone of Russia is dominated by heaving soils, they require «stock» depth for reliability. The average depth of foundations on these soils are 150 cm.

The construction of the Foundation ↑

The procedure works during the construction of pier Foundation ↑

- Manual drill in the ground, make a cylindrical hole 20 cm wide and 100 cm deep.

- The bottom is filled with 10-15 cm of gravel.

- Turning the cylinder a layer of roofing felt, let it down into the hole – it waterproofing and formwork.

- Poured concrete, can withstand 10 days.

- After hardening of a solution on top of the posts set concrete or metal slab.

Pile-screw Foundation ↑

Piles screwed into the ground using special devices, controlling the pile level. On top of the pile equip metal or a reinforced concrete slab.

The construction of strip Foundation ↑

- Around the perimeter of the future basement dig a ditch taking into account the width of the formwork.

- Mount the formwork.

- Poured sand-gravel cushion 10 cm, mounted reinforcement reinforcement and pour concrete.

- Clean the formwork, voids filled with soil, tamped.

Construction of monolithic Foundation ↑

Look at the technology of the device monolithic Foundation for kiln, reinforced wire mesh.

- Dig a pit to a depth below frost penetration. Pit width by 10 – 20 cm longer than the planned width of the Foundation required for formwork.

- The bottom is filled with 15тисантиметровый layer of sand. Sand shed water as long as he does not stop to settle, constantly adding the layer to the required thickness. Then put a layer of broken bricks (20 cm), also sprinkling it with sand and spilling water. On top add 10 cm of gravel and thoroughly tamped.

- Prepared «pillow» cover with two layers of roofing material.

- Inside the pit formwork is mounted so that its top edge was 10-15 cm below the floor level. Between the wall of the pit and the outer casing, leaving a 10 cm gap. The formwork thoroughly moisturize.

- On the bottom pour the starting layer of concrete 4-5 cm thick After it firmly, then laying the reinforcement mesh. It is possible to prepare yourself or buy ready-made option.

- Concrete is poured in stages, in layers 20 cm thick. Each layer «pritoptyvaya» to remove the air. The last layer is poured to exhibited marks and adjust the level.

- After shvatyvanija a solution prepared plate covered with foil and occasionally wet Period curing – three weeks, but with the addition of special additives in concrete, it can be shortened to one week.

- The formwork is dismantled, the empty space filled with rubble.

The device rubble concrete Foundation ↑

Dig a pit the same size, as in the device monolithic Foundation.

- The bottom is filled with 10-15 cm of gravel, tamped. Check level.

- Mount the formwork.

- Inside the formwork coated with bitumen or with roofing material cover. Then spread a layer of stones with a diameter up to 15 cm, the space between them filled with rubble.

- Pour a layer of cement mortar (1 part cement, 3 parts sand). If Foundation depth is small, the layers are poured in one go. If more than half a meter, then several, with a break in the day.

- The top output level 6-7 inches below the finished floor level and smooth down. Cover with foil and kept for weeks.

Regardless of what kind of Foundation is chosen for the base of the furnace in the house or in the bath, are working slowly, soaking all the required timeframe. After all, Foundation is the key to long and trouble-free operation of the furnace.

Dig a pit the same size, as in the device monolithic Foundation.

Dig a pit the same size, as in the device monolithic Foundation.